Manual thread feeding mechanism

A wire feeding and machine body technology, applied in the field of manual wire feeding mechanism, can solve the problems of increased equipment complexity and energy consumption, insufficient reserved length of wire feeding, inconvenient cutting with scissors, etc. The effect of inconvenient cutting and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further introduced below in conjunction with the drawings and specific embodiments.

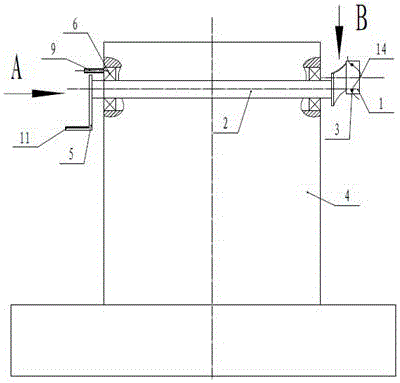

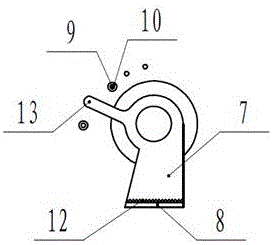

[0018] Such as Figure 1~3 As shown, a manual wire feeding mechanism includes a wire pulling piece 1 and a rotating shaft 2. The pulling piece 1 is provided with two wire pulling holes 3, the rotating shaft 2 is rotatably connected to the body 4, and one end is fixedly connected To the side of the cable piece 1, the other end is fixedly connected with the shake handle 5. After passing the thread 14 through the first hole on the front side of the cable piece, pass the second hole on the outside of the cable piece 1, and rotate the rotating shaft , The thread can be pulled forward, so that after the keyhole is completed, a section of thread is reserved for easy cutting.

[0019] Preferably, the above-mentioned cable pulling piece 1 has a bent L-shaped structure, and the structure is simple, and the above-mentioned two cable holes 3 are arranged vertically in a line, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com