Underhand sublevel open stoping method

A mining method and open field technology, applied in the field of downward segmented open field mining method, can solve the problems of chassis loss, capital and ore backlog, frontal dilution, etc., and achieve the effect of avoiding capital backlog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

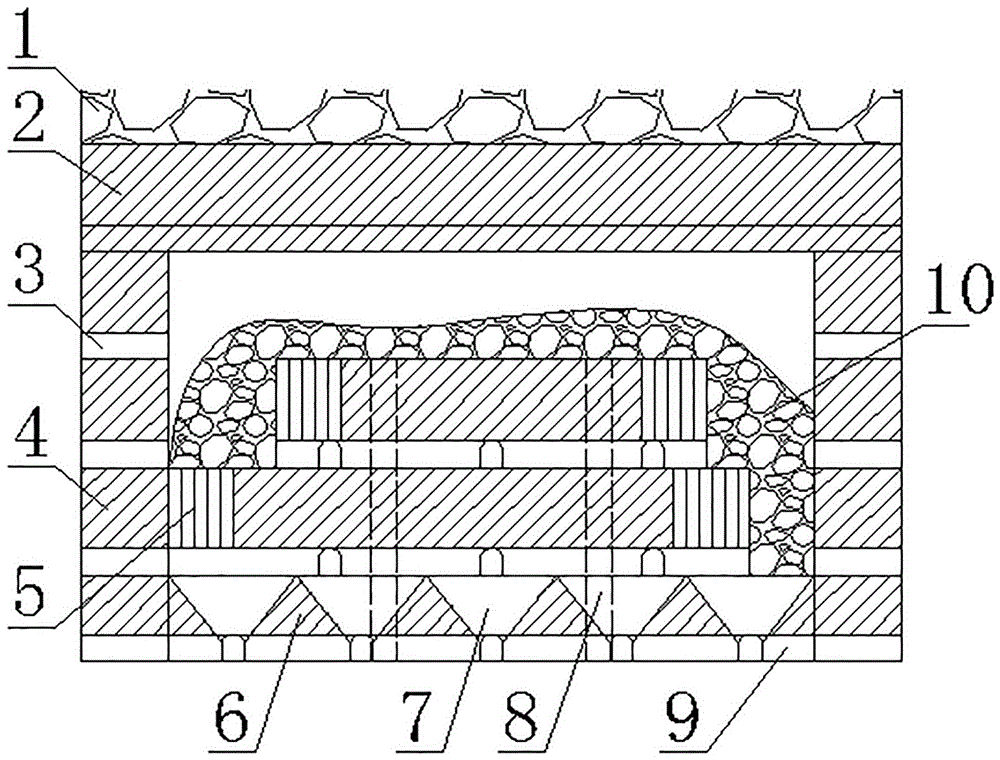

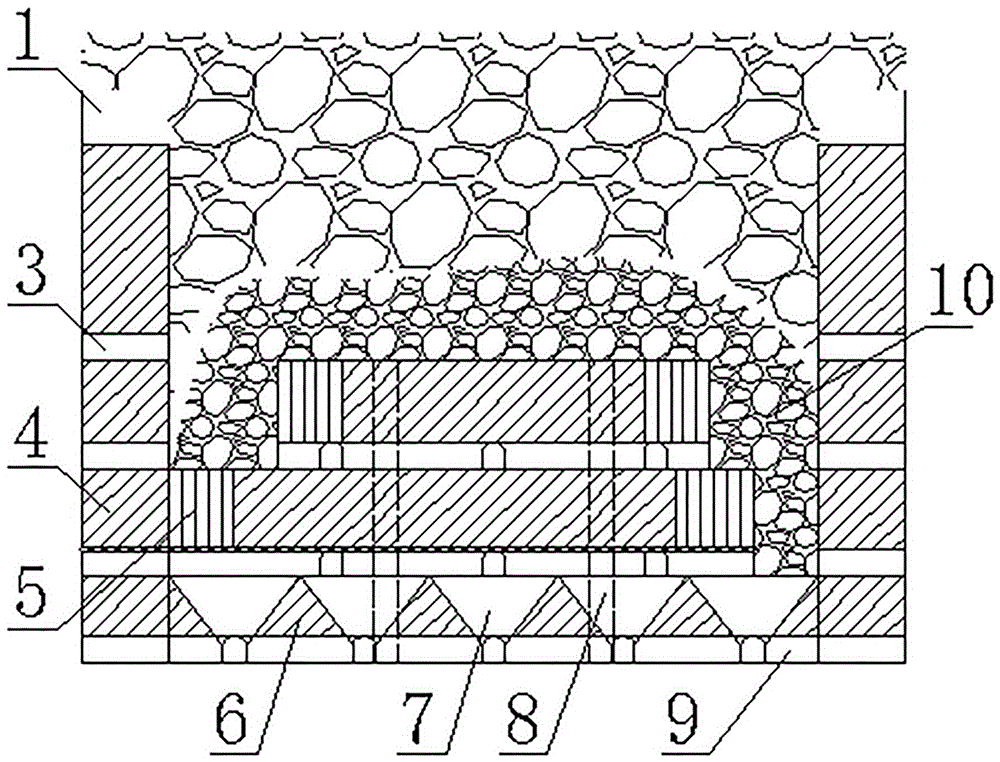

[0018] see figure 1 and figure 2 , the present invention is further described:

[0019] The thickness of the 875-975 line of the 3# ore body in the west of a certain copper mine is small. If the sub-section caving mining method without pillars is adopted, not only the ore will be diluted, but also a large amount of chassis loss will easily occur in the footwall of the ore body, and the recovery effect will not be good. Obviously; it was originally planned to use the stage mine method for mining, but due to the long preparation time of the stage mine method ore block (calculated to take 5 years), and the well-developed surrounding rock schistography, the application of the stage mine method in this area is limited. After many arguments, it was decided to adopt the downward segmented empty field method as the experimental plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com