Rail guide device capable of automatically sealing

A track-guided, self-sealing technology, used in linear motion bearings, installations, large fixed members, etc., can solve problems such as it is difficult to fundamentally avoid the entry of pollutants, and achieve the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

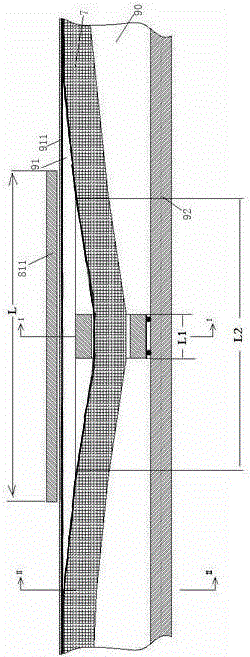

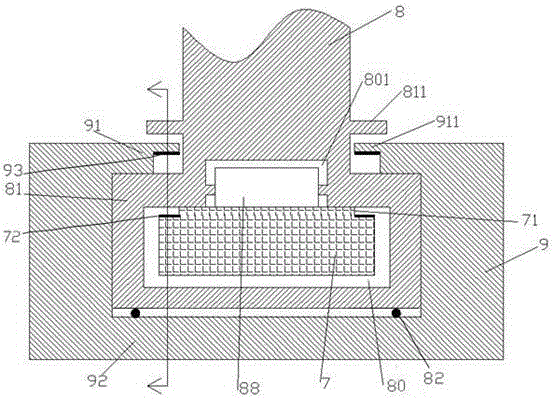

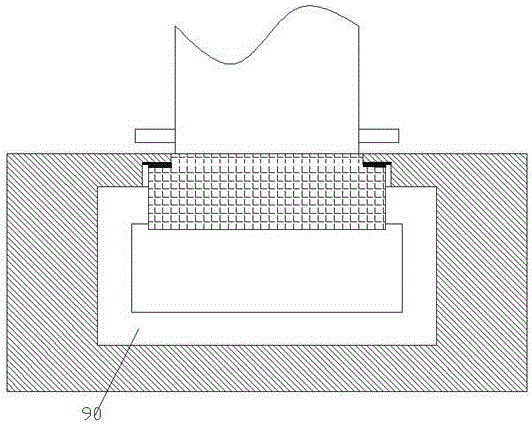

[0010] Combine below Figure 1-3 The present invention will be described in detail.

[0011] According to an embodiment, a self-sealing track guide device includes a guide rail 9 and a slide base 8 that is slidably fitted with the guide 9 and fixedly connected with the slide. The guide 9 includes an upper The side wall 91 and the bottom wall 92 thus define the housing of the guide rail sliding cavity 90 therebetween, and the sliding member base 8 has a sliding engagement seat 81 fitted in the guide rail sliding cavity 90 and is integrated with the sliding engagement seat 81 The connecting neck that is connected and protrudes upwards through the longitudinal groove of the guide rail in the upper side wall 91 is used to be fixedly connected with the sliding part. The bottom of the sliding joint seat 81 is equipped with a roller 82, and the roller 82 is used for To abut against the bottom wall 92, so that the sliding joint seat 81 can run smoothly in the slide cavity 90 of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com