Roll guide checking platform and checking method for finishing mill and pre-finishing mill

A calibration method and pre-finishing technology, applied in the direction of angle/taper measurement, etc., can solve the problems of low production efficiency, inability to guarantee the accuracy of rolling conditions, and poor reliability, so as to improve the accuracy and reduce the replacement of guides and guards Effects of Time and Reliability Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

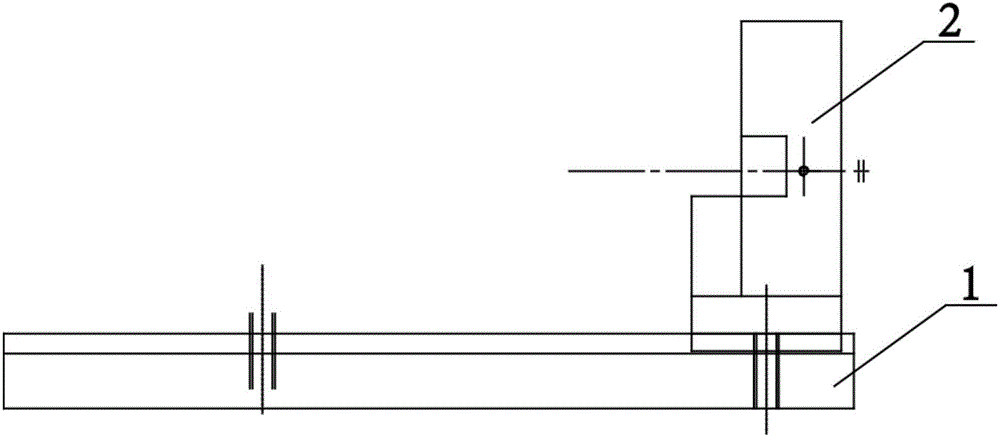

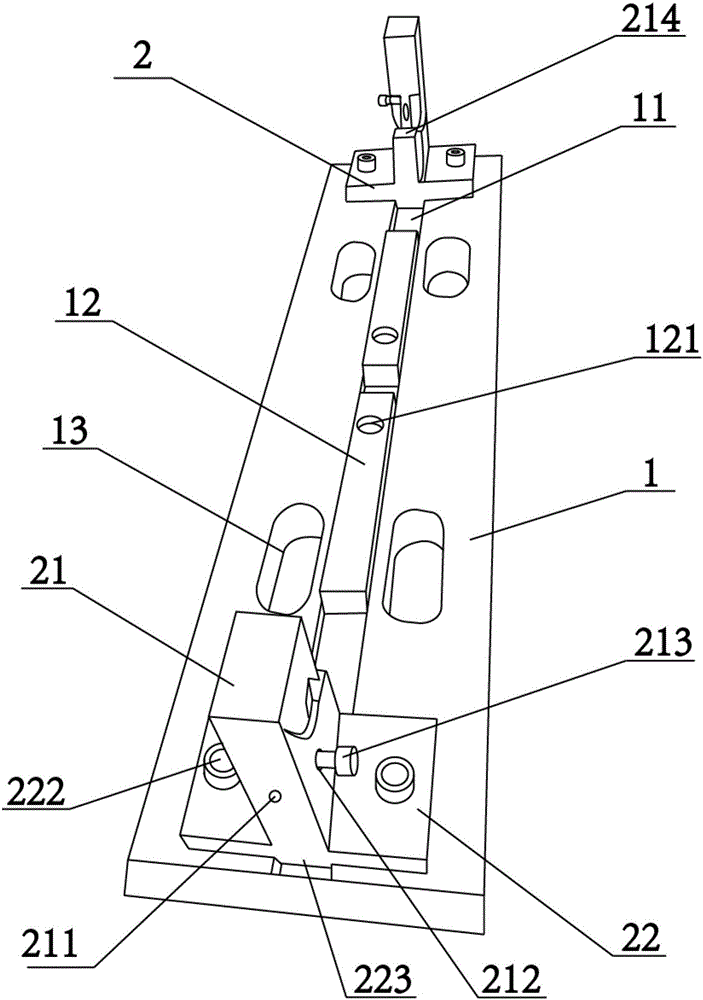

[0034] An embodiment of the present invention provides a guide verification platform for a finishing mill and a pre-finishing mill, including a platform base 1 and a bar ruler 2, the bar ruler 2 is mainly used to ensure the position and accuracy of the bar, specifically structure as attached figure 1 , attached figure 2 And attached image 3 shown. The sample rod ruler 2 is located above the platform base 1, and the sample rod ruler 2 is fixedly connected with the platform base 1. The number of sample rod rulers 2 can be set according to the actual calibration needs. In this embodiment, there are two sample rod rulers 2 , which are symmetrically arranged at both ends of the platform base 1 .

[0035] Further, a groove 11 is opened on the platform base 1, and the cross section of the groove 11 is rectangular. The platform base 1 is also provided with several guide installation holes 13 and gauge installation holes 14, the guide installation holes 13 and the gauge installat...

Embodiment 2

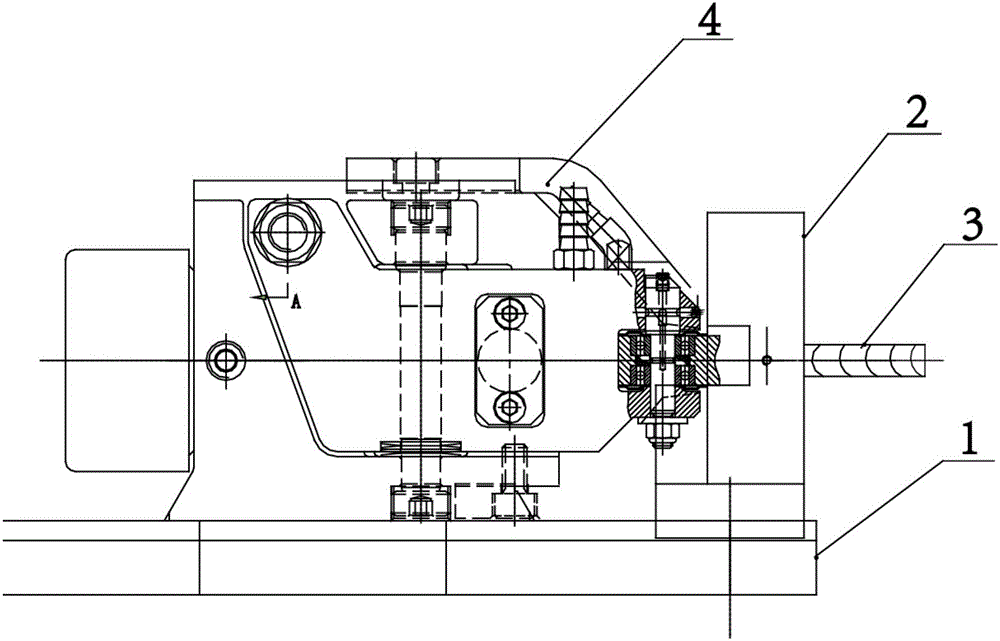

[0044] An embodiment of the present invention provides a guide verification platform for a finishing mill and a pre-finishing mill, including a platform base 1 and a bar ruler 2, the bar ruler 2 is mainly used to ensure the position and accuracy of the bar 3, The specific structure is attached Figure 4 And attached Figure 5 shown. The sample rod ruler 2 is located above the platform base 1, and the sample rod ruler 2 is fixedly connected with the platform base 1. The number of sample rod rulers 2 can be set according to actual calibration needs. In this embodiment, the number of sample rod rulers 2 is four, and each two is a group, which are respectively symmetrically arranged at both ends of the platform base 1 .

[0045] Further, a groove 11 is opened on the platform base 1, and the cross section of the groove 11 is rectangular. The platform base 1 is also provided with several guide installation holes 13 and gauge installation holes 14, the guide installation holes 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com