Automatically Controlled Computer Host Cooling System

A cooling system and computer technology, applied in computing, instruments, electrical and digital data processing, etc., can solve the problems of computer paralysis, inconvenience in people's life and work, slow running speed, etc., and achieve convenient positioning and fixing, convenient detection, and convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

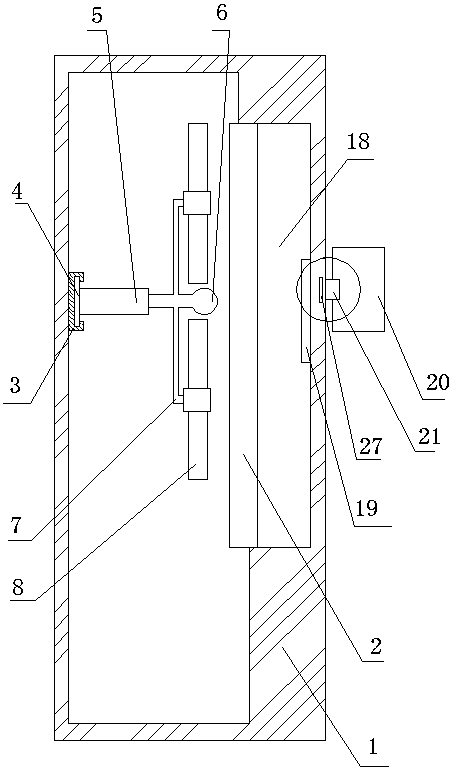

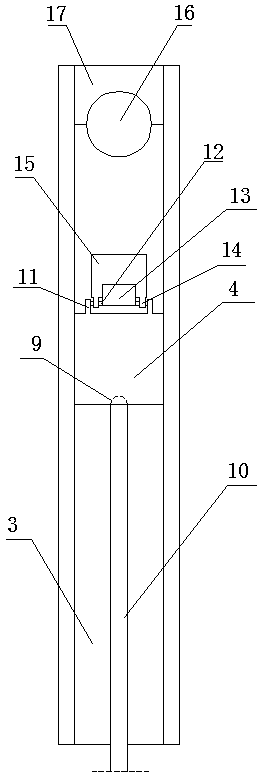

[0029] An automatically controlled cooling system for a mainframe computer, which consists of: a probe 6, a mainframe 1, a mainboard 2, the mainframe 1 is loaded with the mainboard 2, and the left end of the inner surface of the mainframe 1 (the distance from the mainboard is far inner surface) to install the slideway 3, the slider 4 slides on the slideway 3, the slider 4 is connected to the telescopic rod 5, and the top end of the telescopic rod 5 is connected to the probe 6, and the telescopic rod 5 is connected to the probe 6. The inner rod of rod 5 is connected with L-shaped hollow rod 7, and fan 8 is connected on the described L-shaped hollow rod 7, and the outer end of described slide block 4 has arc-shaped groove 9, and described arc-shaped groove 9 is used in conjunction with the push rod 10, the inner end of the slider 4 is connected to the shaft 12 through the shaft sleeve I11, the orientation piece 13 is connected to the shaft 12, the shaft sleeve II14 is connected t...

Embodiment 2

[0031] In the automatically controlled computer mainframe heat dissipation system described in Embodiment 1, thermocouples 19 are placed in the empty groove 18 at the right end of the inner surface of the main board 2 and the main chassis 1, and the thermocouples 19 and the probes 6 are connected to the temperature Sensor, the temperature sensor includes an outer casing 20 , and the outer casing 20 is connected to the right end of the outer surface of the main chassis 1 through an elastic clip 21 .

Embodiment 3

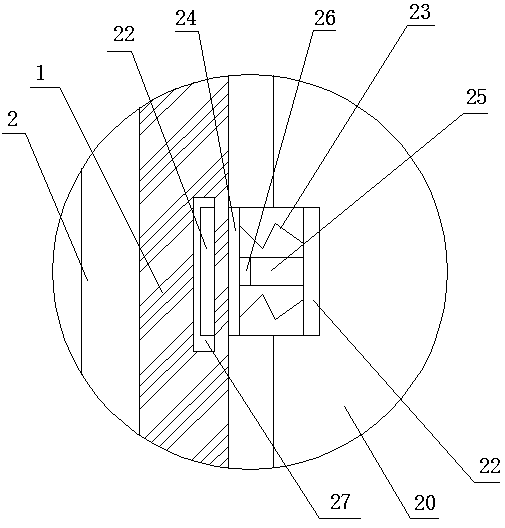

[0033] In the automatic control heat dissipation system for computer mainframes described in Embodiment 2, the elastic clip 21 includes a C-shaped plate 22, the top surface of the C-shaped plate 22 is connected to the spring 23, and the bottom surface of the spring 23 is connected to the pressure plate 24, the pressure plate 24 is arranged in the C-shaped plate 22, the vertical side of the C-shaped plate 22 has a sliding port 25, and the sliding port 25 slides on the fixed block 26, the The fixed block 26 is connected on the pressing plate 24. The right end of the outer surface of the main chassis 1 is provided with an L-shaped slot 27, and the elastic clip 21 is inserted into the L-shaped slot 27.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com