Portable electric equipment inspection device

A technology of electric equipment and inspection devices, which is applied in mechanical equipment, televisions, electrical components, etc., can solve problems such as hidden defects of electronic components, affect the normal use of electrical cabinets, and difficult inspection of components, etc., and achieve good market use effects and promotion Foreground, improve inspection work efficiency, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

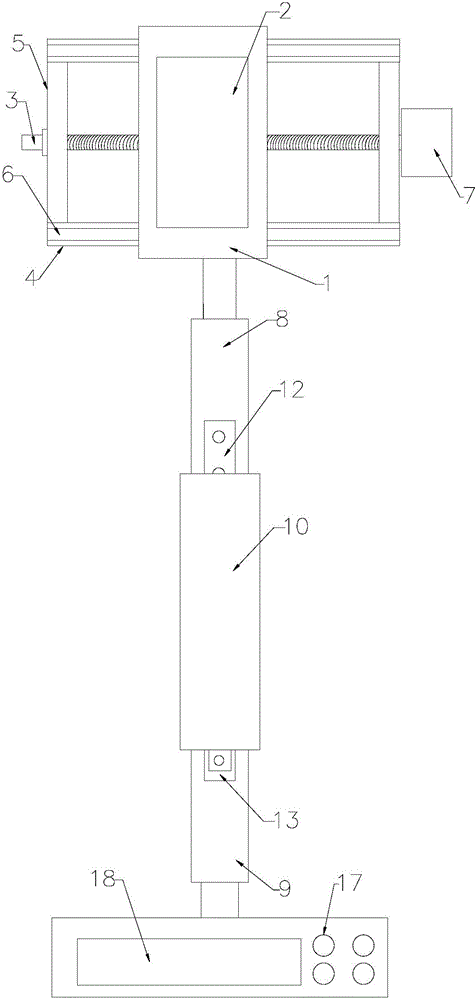

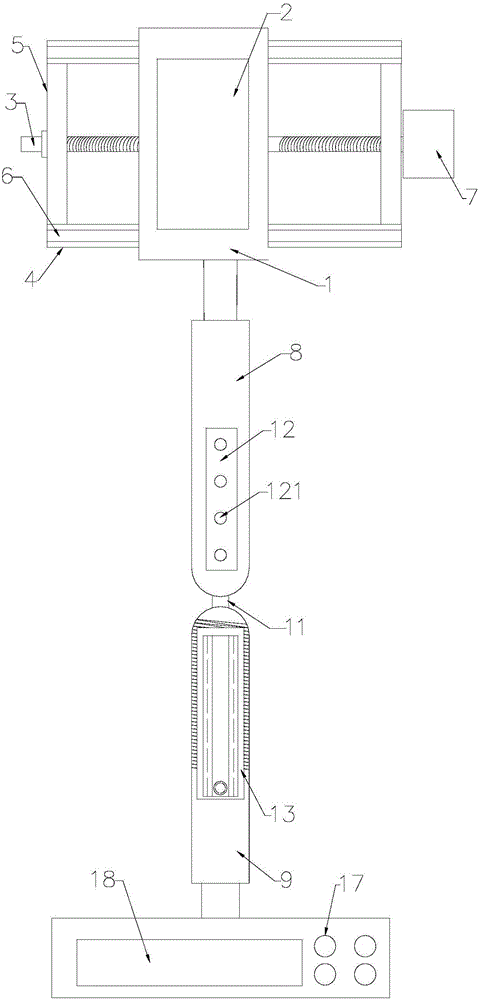

[0043] see figure 1 , figure 2 , Figure 4 to Figure 15 , In this example, it includes a video capture device, a monitoring device, and a support device. The top of the monitoring device is connected to the support device and the video capture device in sequence from bottom to top. It is characterized in that: the video capture device includes a guide frame body, a base 1. The camera 2, the front side of the guide frame body is horizontally connected to the back side of the base 1, and the camera 2 is fixed on the front side of the base 1. In this example, the guide frame body includes a square frame composed of two upper and lower horizontal bars 4 and two left and right vertical bars 5. The horizontal bar 4 is provided with a sliding rail 6 along the length of the horizontal bar 4, which is connected with the sliding rail 6. A sliding block is provided on the base 1 corresponding to the rail 6 , and the sliding block is nested in the sliding rail 6 to realize the sliding ...

Embodiment 2

[0055] This example is basically the same as Example 1, except that in the bendable support device described in this example, the upper support rod 8 and the lower support rod 9 are axially connected, and the upper support rod 8 is wound vertically upward and downward. The shaft joint of the support rod 9 rotates.

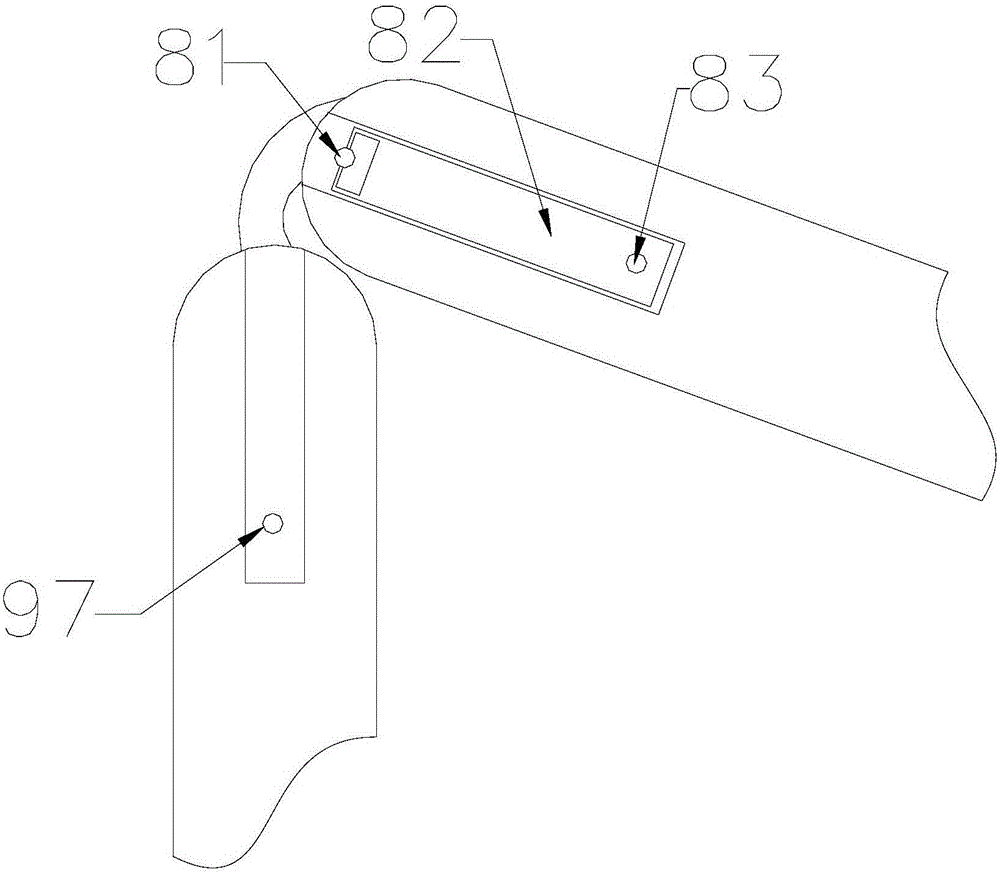

[0056] In addition, the straightening device in this example is to set an upper embedding groove along the length direction of the upper supporting rod 8 at the lower part of the outer wall of the upper supporting rod 8, and this upper embedding groove and the groove 12 are located on different sides of the upper supporting rod 8, A lower insert groove is set along the length direction of the lower support bar 9 at the upper part of the outer wall of the corresponding lower support bar 9; The other end of the straight rod 82 is provided with a cylindrical member 97; and one end of the straight rod 82 is rotatably connected to the upper or lower embedded groove in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com