Steering spline telescoping shaft, and steering device

A rolling radius, adhesion technology, applied in the direction of brakes, external condition input parameters, control devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

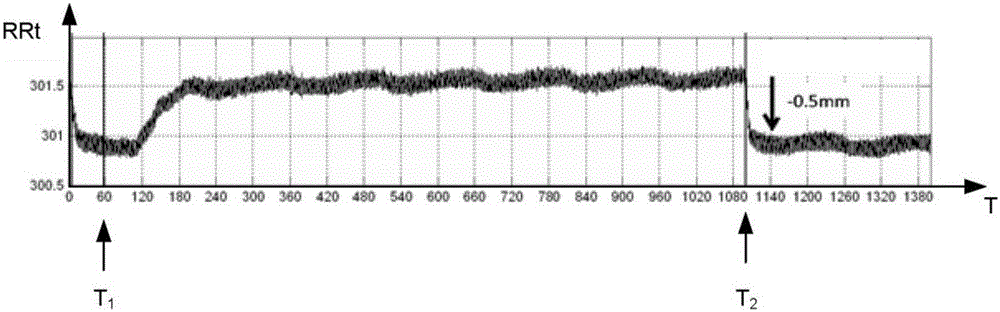

[0062] figure 1 shows the phenomenon on which the invention is based, by which it is conceivable to measure the non-driven and non-steered wheels successively at 0 and T while the vehicle is traveling in a straight line at a constant speed 1 Driving on wet ground between, T 1 with T 2 Driving on dry ground between and on T 2 The rolling radius when driving on wet ground again afterwards.

[0063] It can be seen that the rolling radius RRt increases by 0.5 mm when changing from driving on wet to dry ground and decreases by the same amount when changing from driving on dry to wet ground.

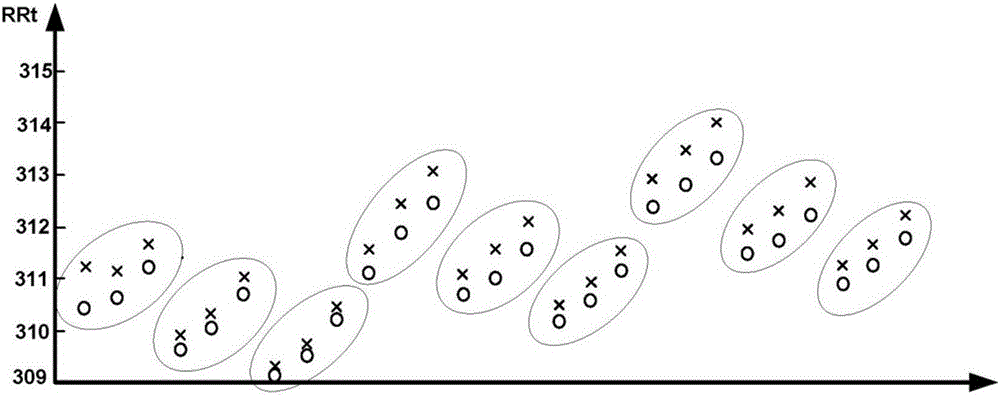

[0064] figure 2 This experimental protocol was reproduced for different speeds, actual load conditions and inflation pressures. It can still be seen that the rolling radius changes when changing from being on a dry ground (indicated by a cross) to being on a wet ground (indicated by a circle) and vice versa.

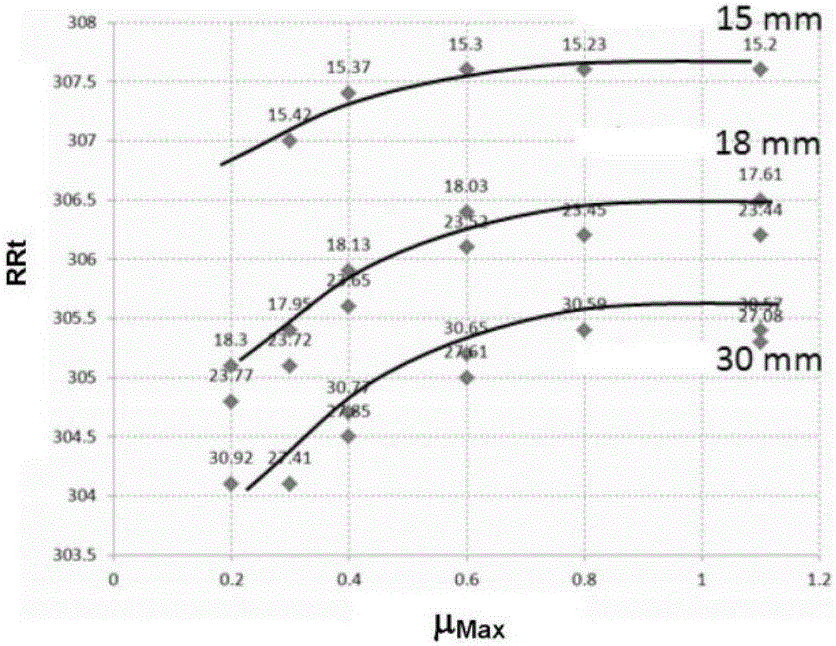

[0065] The method then includes establishing the rolling radius from an equat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com