Follow-up lawn mower head drive

A transmission device and lawn mower technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as complex structure, large inclination angle of V-shaped transmission belt, difficult to control the quality of parts and assembly quality, and achieve extended use The effect of long life, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

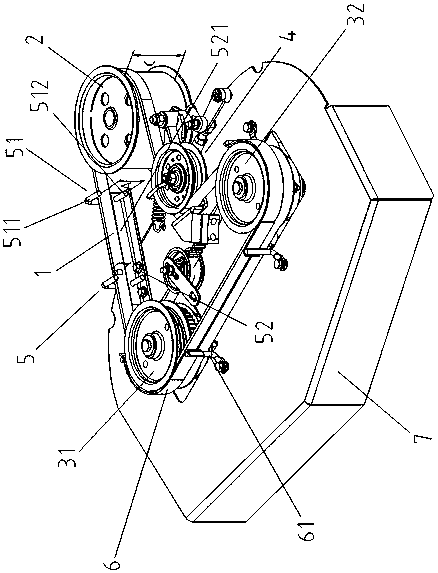

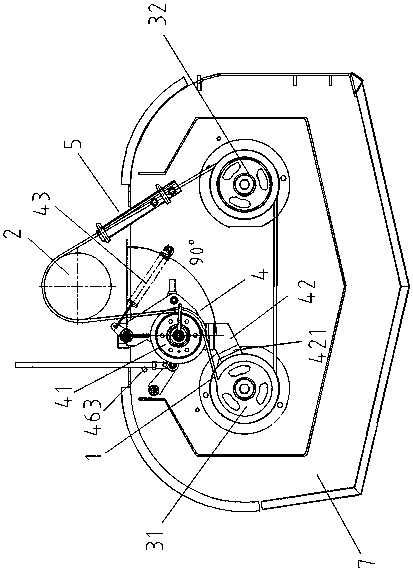

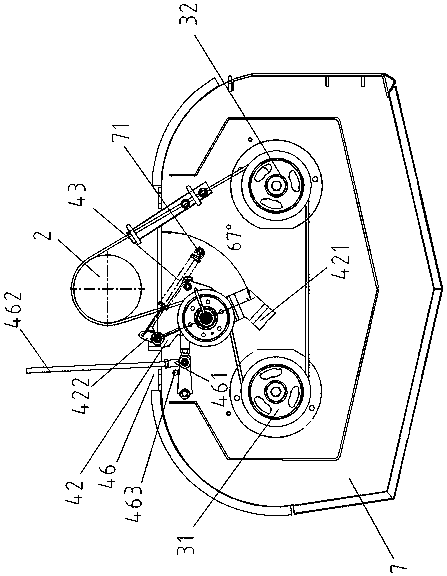

[0020] Such as Figure 1 ~ Figure 4 Shown, the present invention comprises flat belt 1, engine pulley 2, two cutter pulleys and tensioner mechanism 4, prevents that flat belt slip-off mechanism 5 is arranged on the flat belt between engine pulley 2 and the first cutter pulley 31 1 outside, the outside of two cutter belt pulleys is respectively provided with retaining belt cover 6. The flat belt 1 walks around the engine pulley 2 and the two cutter pulleys in turn, and the tensioner mechanism 4 is positioned outside the engine pulley 2 and the second cutter pulley 32 and leans against the flat belt 1 .

[0021] The mechanism 5 for preventing the flat belt from falling out of groove comprises two belt brackets 51 and an L-shaped base 52. The belt bracket 51 is in a U-shape toppled over. The vertical fixed welding is connected, and the L-shaped base 52 is made of angle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com