Composite dry powder fire extinguishing agent and its preparation method

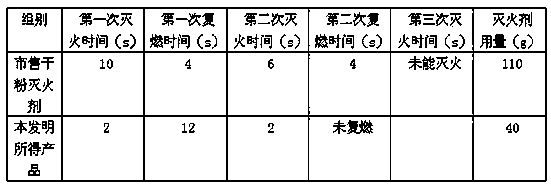

A drying and silicon nitride technology, which is applied in the direction of fire prevention equipment, etc., can solve the problems of poor fire extinguishing effect, scattering by wind, and difficulty in adhesion, etc., and achieve good fire extinguishing performance, high fire extinguishing efficiency and strong moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Composite dry powder fire extinguishing agent is prepared from the following main raw materials in parts by weight (each part is 1000g): 30 parts of alkali slag, 15 parts of sodium bicarbonate, 12 parts of potassium sulfate, 10 parts of magnesium carbonate powder, polybutylene 2 parts of alkene, 3 parts of ammonium sulfate, 8 parts of gypsum, 4 parts of chlorinated rubber, 3 parts of zinc borate, 1.5 parts of tin oxide, and 0.8 parts of silicon nitride.

[0033] The preparation method of above-mentioned composite dry powder fire extinguishing agent is:

[0034] (1) Take silicon nitride, add water and polymethacrylic acid, the quality of water is 1 / 7 of the mass of silicon nitride, and the weight of polymethacrylic acid is 0.05% of the mass of silicon nitride, put it into a ball mill tank, Grinding, grinding for 65 hours, sieving to remove the grinding medium, drying, grinding, and sieving;

[0035] (2) Separately pulverize alkali slag, polybutene, gypsum, chl...

Embodiment 2

[0037] Example 2 The composite dry powder fire extinguishing agent is prepared from the following main raw materials in parts by weight (each part is 1000g): 38 parts of alkali slag, 22 parts of sodium bicarbonate, 18 parts of potassium sulfate, 15 parts of magnesium carbonate powder, polybutylene 5 parts of alkene, 7 parts of ammonium sulfate, 14 parts of gypsum, 9 parts of chlorinated rubber, 6 parts of zinc borate, 3.5 parts of tin oxide, and 1.8 parts of silicon nitride.

[0038] The preparation method of above-mentioned composite dry powder fire extinguishing agent is:

[0039] (1) Take silicon nitride, add water and polymethacrylic acid, the quality of water is 1 / 3 of the mass of silicon nitride, and the weight of polymethacrylic acid is 0.1% of the mass of silicon nitride, put it into a ball mill tank, Grinding, grinding for 85 hours, sieving to remove the grinding medium, drying, grinding, and sieving;

[0040] (2) Separately pulverize alkali slag, polybutene, gypsum,...

Embodiment 3

[0042] Example 3 The composite dry powder fire extinguishing agent is prepared from the following main raw materials in parts by weight (each part is 1000g): 33 parts of alkali slag, 17 parts of sodium bicarbonate, 14 parts of potassium sulfate, 11 parts of magnesium carbonate powder, polybutylene 2.5 parts of alkene, 4 parts of ammonium sulfate, 10 parts of gypsum, 5 parts of chlorinated rubber, 4 parts of zinc borate, 2 parts of tin oxide, and 1.2 parts of silicon nitride.

[0043] The preparation method of above-mentioned composite dry powder fire extinguishing agent is:

[0044] (1) Take silicon nitride, add water and polymethacrylic acid, the quality of water is 1 / 6 of the mass of silicon nitride, and the weight of polymethacrylic acid is 0.07% of the mass of silicon nitride, put it into a ball mill tank, Grinding, grinding for 68 hours, sieving to remove the grinding medium, drying, grinding, and sieving;

[0045] (2) Separately pulverize alkali slag, polybutene, gypsum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com