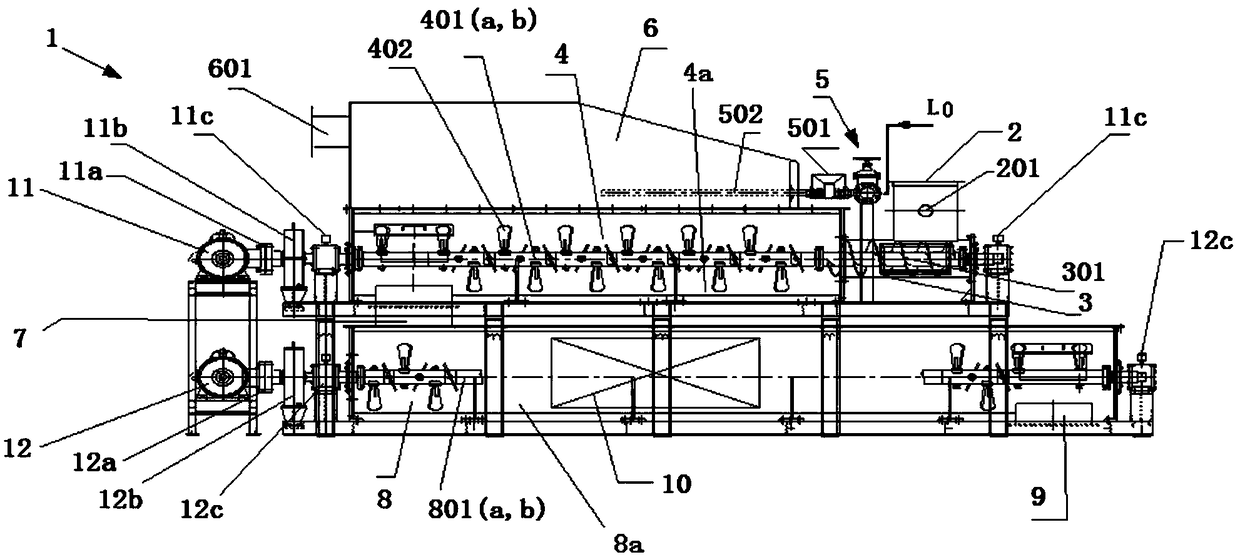

A water bath deduster, dedusting method, and quicklime digestion and dedusting device

The technology of dust collector and water bath is applied in the field of quicklime digestion and dust removal in iron and steel sintering plants, which can solve the problems of sewage environmental pollution, dust and flue gas environmental pollution, poor quicklime digestion and dust removal, etc., and achieve the effect of ensuring stable and efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

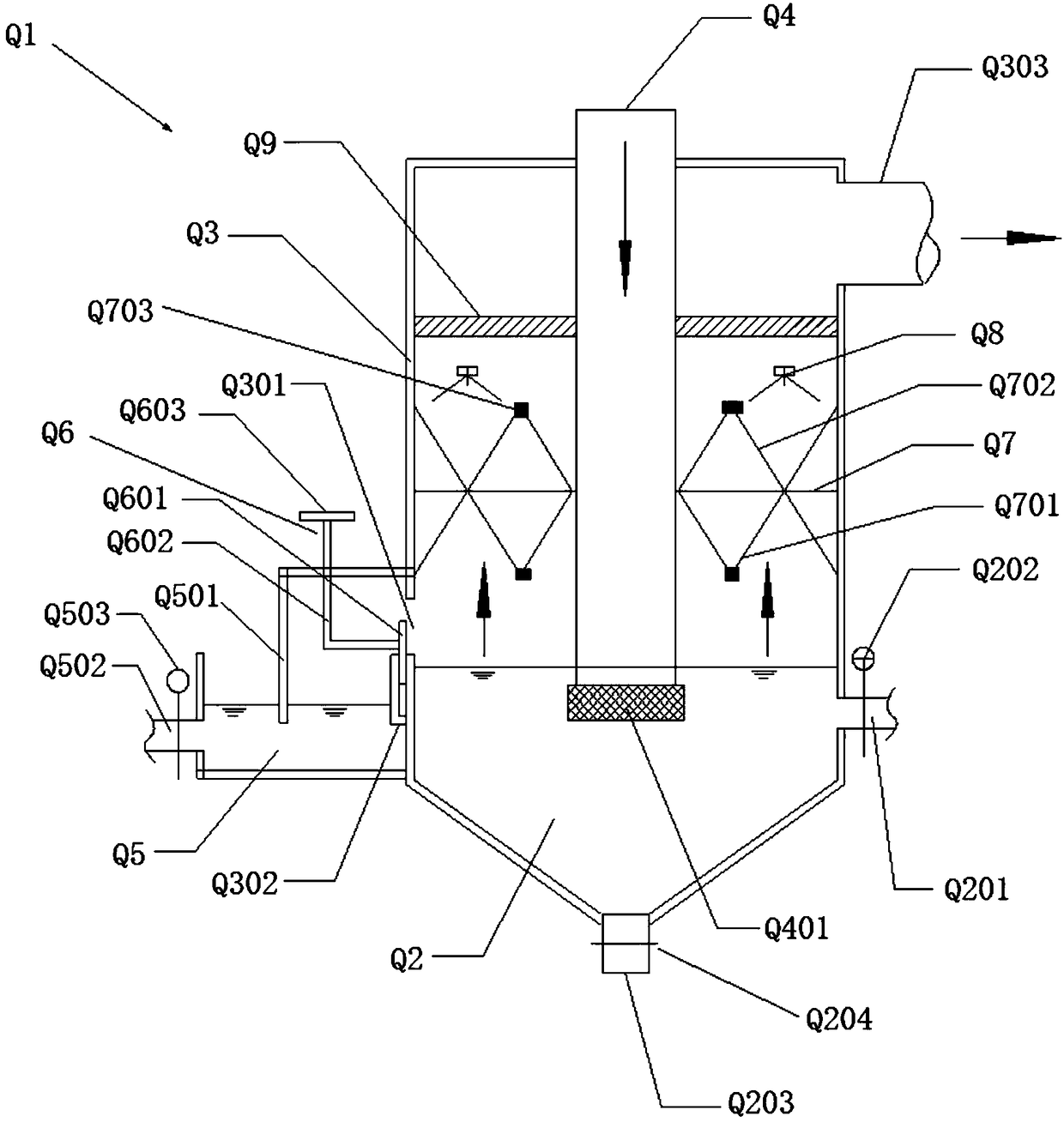

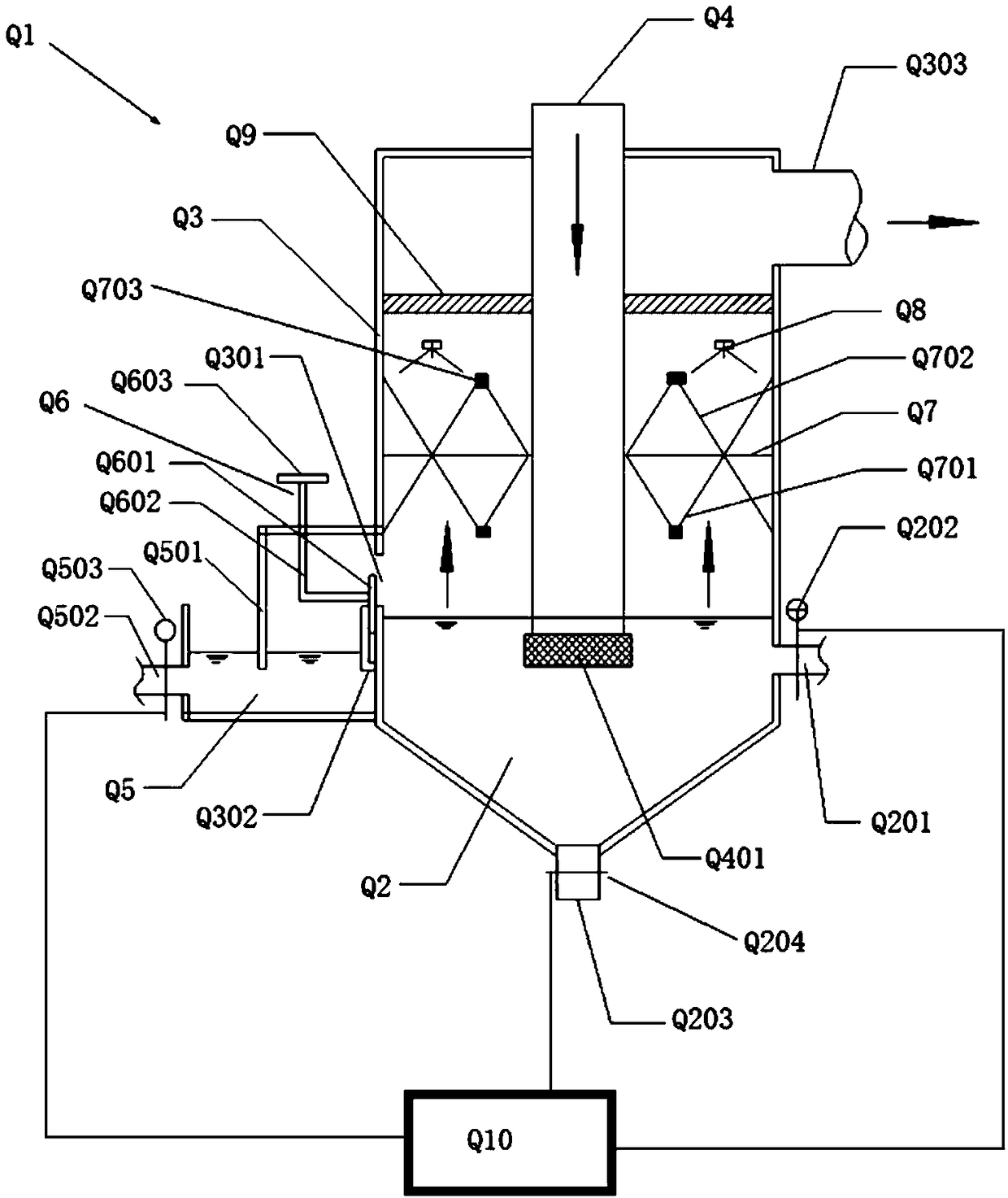

[0110] According to the second embodiment provided by the present invention, there is provided a method for using a water-bath dust collector or a method for removing dust using the above-mentioned water-bath dust collector, the method comprising the following steps:

[0111] (1) Store water in the dedusting pool through the water supply pipe Q201, adjust the water level regulating plate Q601, make the water level in the dedusting pool Q2 reach a predetermined value, and close the water supply pipe valve Q202;

[0112] (2) Dusty gas (such as dust and flue gas from the dust removal port of the quicklime digester) enters the dust collector Q1 from the middle of the dust collector housing Q3 through the dust removal pipe Q4 from top to bottom. The flow rate is adjusted by adjusting the water level adjustment device Q6 so that the dust removal pipe Q4 is inserted into a certain position in the dust removal pool Q2, and the end of the dust removal pipe Q4 inserted into the water is ...

Embodiment 1

[0135] A water bath dust collector, the dust collector Q1 includes:

[0136] Dust removal pool Q2;

[0137] The dust collector housing Q3 located above the dust removal pool Q2;

[0138] Dust removal pipe Q4,

[0139] One end of the dust removal pipeline Q4 is externally connected to the dust removal interface of the lime digester, and the other end passes through the dust collector housing Q3 from top to bottom and extends into the dust removal pool Q2 below the dust collector housing Q3. One end of the dust removal pipeline Q4 extending into the dust removal pool Q2 is provided with a submerged pipeline nozzle Q401. Wherein the end of the submerged pipeline nozzle Q401 is a network structure or a porous structure.

[0140] The dust removal pipe Q4 passes through the middle of the dust collector housing Q3.

[0141] The dust remover Q1 also includes: an overflow water sealing pool Q5 located on one side of the dust removal pool Q2. Between the dust removal pool Q2 and th...

Embodiment 2

[0154] Embodiment 1 is repeated, except that an overflow pipe valve Q503 is provided on the overflow pipe Q502. The water supply pipe Q201 is provided with a water supply pipe valve Q202.

[0155] In this embodiment, the dust removal efficiency reaches 99.9%. The device of this embodiment can realize real-time control of the position of the water surface in the dust removal pool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com