Process for quicklime digestion, dedusting and sewage sludge treatment

A treatment process, sewage sludge technology, applied in sludge treatment, dehydration/drying/thickened sludge treatment, water/sewage treatment, etc., can solve the problems of a large amount of waste residue, waste of water resources, etc., to ensure stable and efficient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

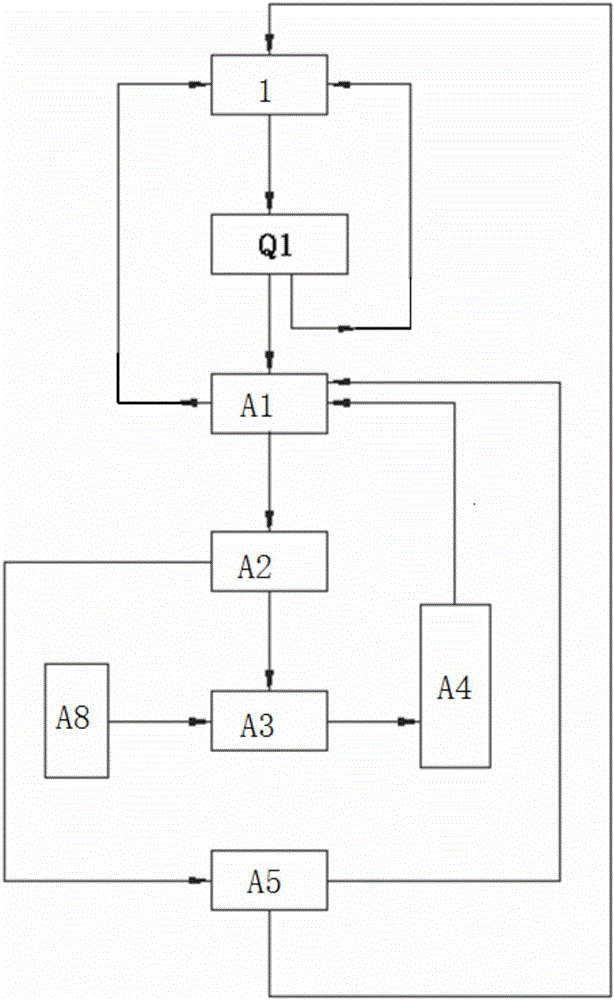

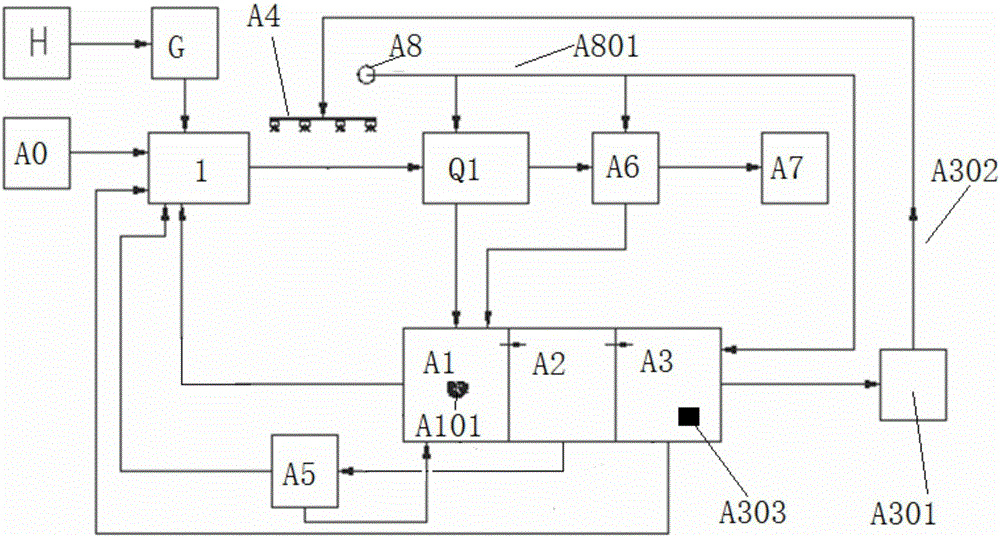

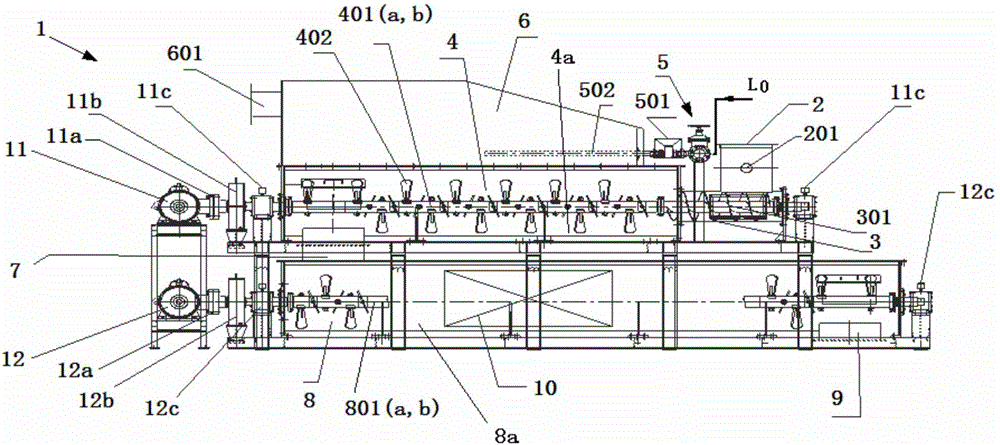

[0167] A quicklime digestion, dust removal and sewage sludge treatment process, comprising the following steps:

[0168] (1) quicklime digestion: put quicklime A0 into two-stage quicklime digester 1 for digestion;

[0169] (2) Dedusting of dust-containing gas: the dust-containing gas in quicklime digester 1 is output to water bath dust collector Q1, and the dust removal sewage in the dust removal pool at the bottom of water bath dust collector Q1 is discharged into stirring tank A1 or two-stage quicklime digestion Device 1, optionally, the dedusting sewage in the dedusting pool at the bottom of the water bath deduster Q1 is transported to the quicklime digester 1 for use as digestion water;

[0170] (3) The sewage in the stirring tank A1 is discharged into the two-stage quicklime digester 1 or enters the sedimentation tank A2, and the sedimentation tank A2 sediments and separates the sewage, the upper layer is sedimentation water, and the lower layer is sedimentation sludge; ...

Embodiment 2

[0175] Repeat Example 1, except that quicklime digester 1 is a three-stage quicklime digester.

Embodiment 3

[0177] Example 1 was repeated, except that the steelmaking sludge H was transported to the quicklime digester 1 through the sludge pump G.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com