A quicklime digestion water bath dust removal device

A dedusting device and water bath dedusting technology, applied in the direction of separation device, chemical instrument and method, separation method, etc., can solve the problems of dust and flue gas environmental pollution, lime digestion dust removal sewage environmental pollution, quicklime digestion and dust removal effect poor etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

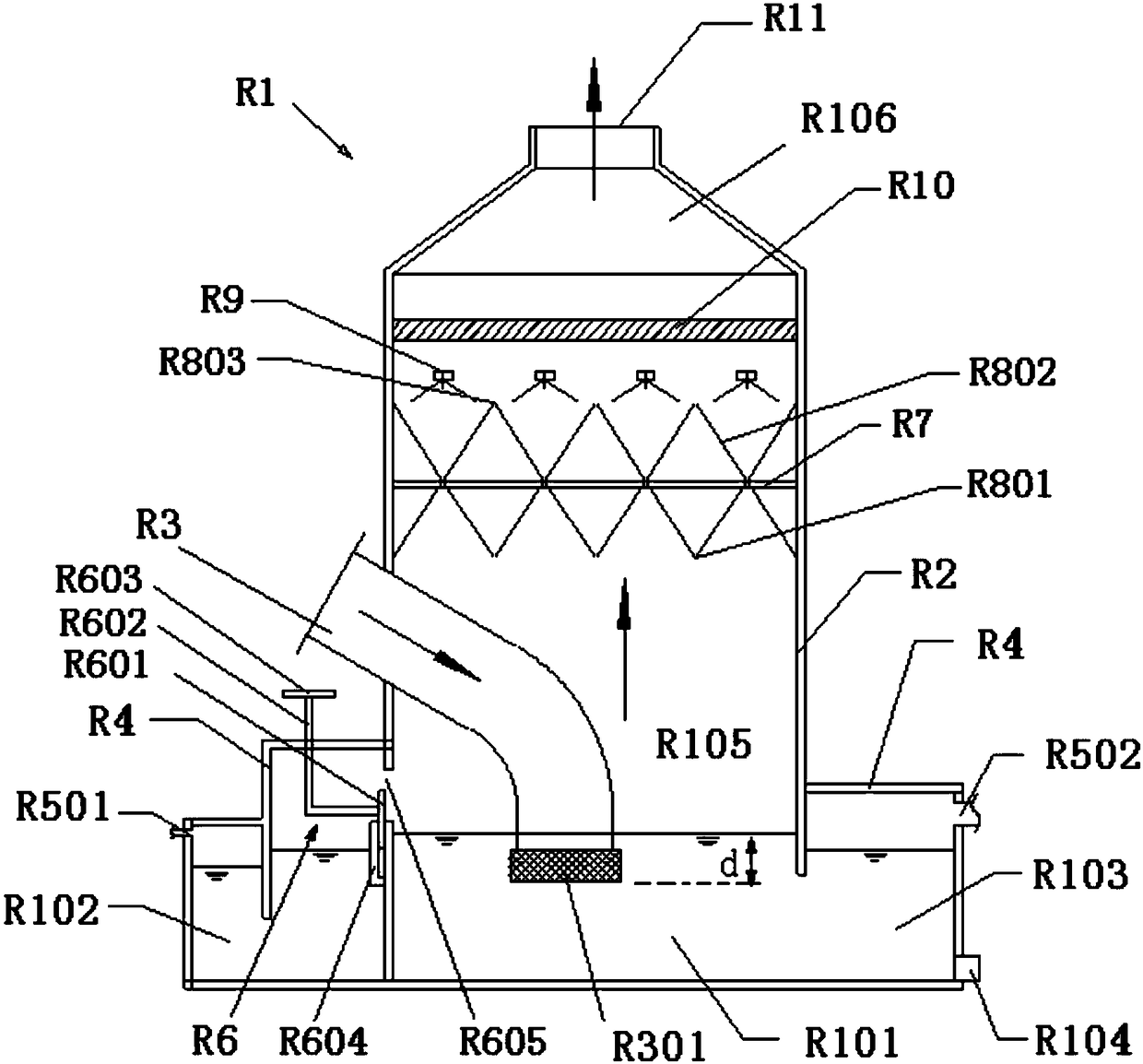

[0146] use as figure 2 In the shown device, before dust removal starts, water is stored in the buffer pool through the water inlet pipe, and the water in the buffer pool flows into the dust removal pool together, and the water level adjustment plate is adjusted to completely cover the water level adjustment hole. When the water level reaches the predetermined water level, close the water inlet pipe, and then adjust the water level in the dust removal pool by adjusting the area and height of the water level adjustment plate to cover the water level adjustment hole. The excess water flows into the overflow water seal pool through the water level adjustment hole. When the overflow water seal When there is too much water in the pool, the overflow pipe can be opened to discharge the excess water.

[0147] The dust flue gas from the dust removal port of the quicklime digester enters the dust collector through the dust removal pipe. The dust removal pipe is inserted into a certain p...

Embodiment 2

[0152] adopted with figure 2 Basically the same equipment, except that the V-shaped filter screen is not arranged under the bracket, dust removal is performed in the same manner as in Example 1, and the dust removal efficiency is 95%.

Embodiment 3

[0158] A method for using quicklime digestion water bath dedusting device, the method comprises the following steps:

[0159] (1) Store water in the buffer pool R103 through the water inlet pipe R502, and the water in the buffer pool R103 flows into the dust removal pool R101 together, adjust the water level adjustment plate R601 to completely cover the water level adjustment hole R605, when the water level in the dust removal pool When the predetermined water level is reached, close the water inlet pipe R502;

[0160] (2) By adjusting the area and height of the water level adjustment plate R601 to block the water level adjustment hole R605 to regulate the water level in the dust removal pool R101, the excess water flows into the overflow water seal pool R102 through the water level adjustment hole R605, when the overflow water seal pool R102 When there is too much water, the overflow pipe R501 can be opened to discharge the excess water;

[0161] (3) Dust and flue gas from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com