A traction rod installation interface device and bogie

A technology of traction rods and installation interfaces, which is applied in the field of rail vehicle manufacturing, can solve the problems of low safety, small lateral adjustment clearance of columns, poor safety, etc., and achieve the effect of ensuring safe operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

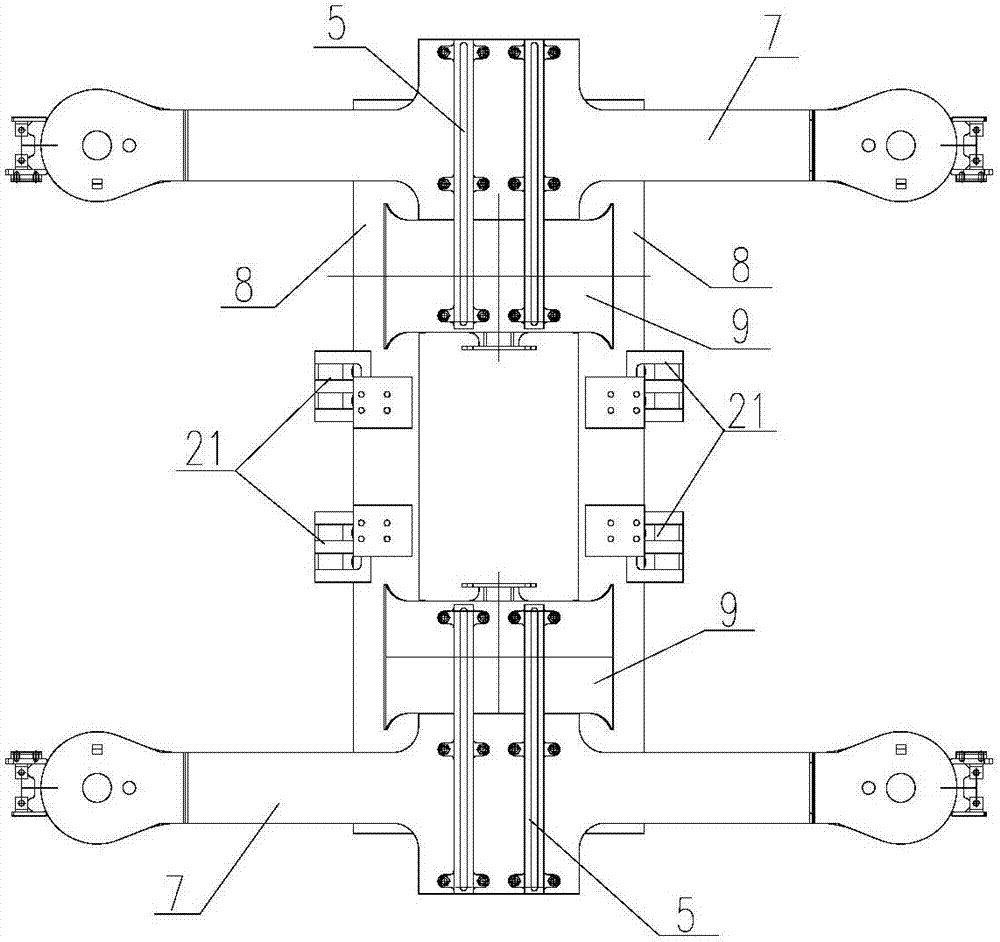

[0084] Such as Figure 21 and Figure 22 As shown, the transported car body adopts a single traction rod, such as CRH6-140 / CRH6-160 and other models. That is, a single traction interface module 22 is installed across the low position, and the installation height of the single traction interface module 22 is adjusted according to the installation height difference between the original air spring installation height of the CRH6 vehicle model and the secondary spring device 2 of the bogie, and Finally, a single traction interface module 22 is bridged and fixed on the two lower traction rod interface mounts 21 a on the same side by bolts.

Embodiment 2

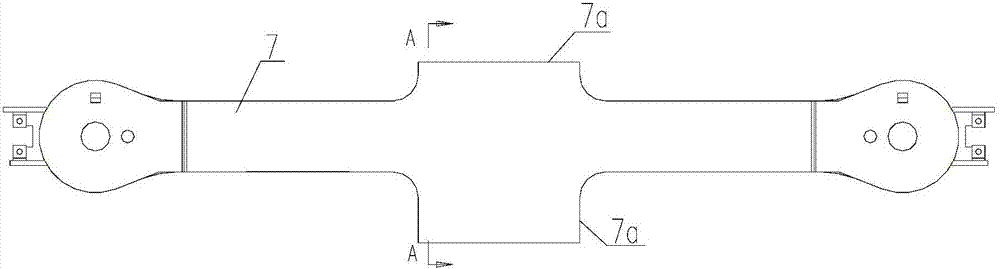

[0086] Such as Figure 23 and Figure 24 As shown, the transported car body adopts low-position double traction rods, such as the Argentine EMU. When transporting the car body of this model, it needs to be installed on the two lower traction rod interface mounting seats 21a on the two beams 8, that is, the low position Install a low-position dual-traction interface module 23 symmetrically at an oblique angle, and adjust the installation height of the two low-position dual-traction interface modules 23 according to the installation height difference between the original air spring installation height of the Argentina EMU and the installation height of the secondary spring device 2 of this bogie , and finally fix the two low-position dual traction interface modules 23 on the two lower traction rod interface mounts 21a by bolts.

Embodiment 3

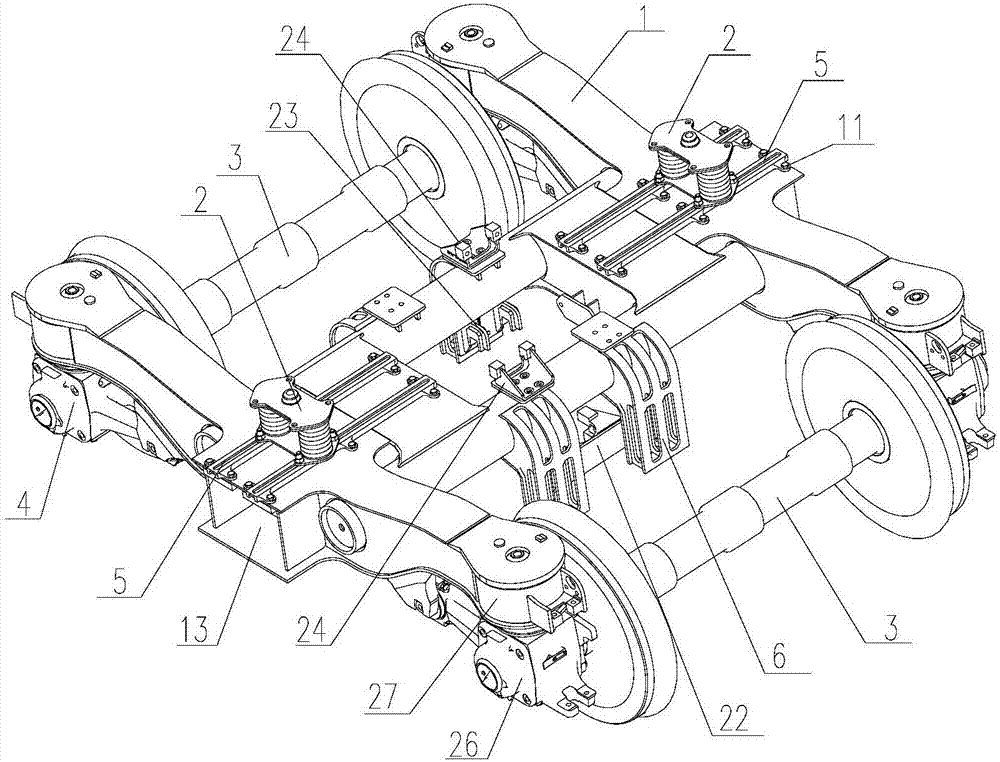

[0088] Such as Figure 25 and Figure 26 As shown, the transported car body adopts high-position double traction rods, such as Guangzhou Metro. When transporting the car body of this model, it needs to be installed on the two upper traction rod interface mounting seats 21b on the two beams 8, that is, the high position A high-position dual-traction interface module 24 is installed symmetrically at an oblique angle. According to the installation height difference between the original air spring of the Guangzhou Metro type and the installation height of the secondary spring device 2 of this bogie, high-position dual-traction interface modules 24 of different heights are selected, and Finally, the two high-position dual traction interface modules 24 are fixed on the two upper traction rod interface mounts 21b by bolts, which avoids the interference of the traction interface modules on the vehicle body when the conventional test vehicle body is transported.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com