A tile automatic laying trolley

A technology of automatic laying and tiles, which is applied in the direction of construction and building construction, can solve the problems of potential safety hazards, tile throwing, tile waste, etc., and achieve the effect of low cost, high efficiency, simple and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

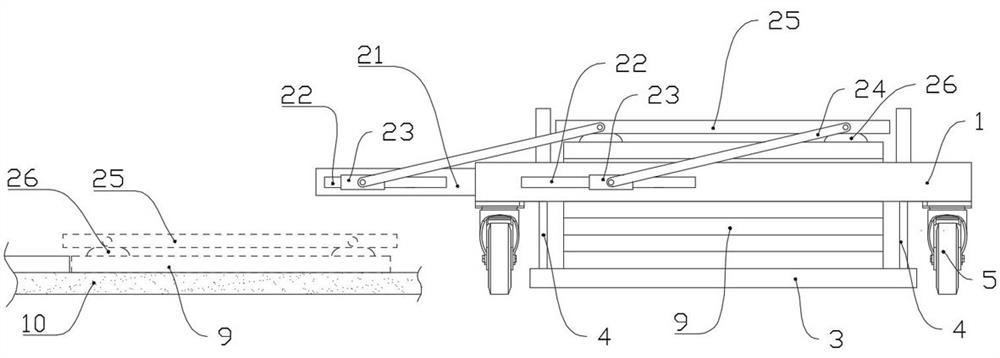

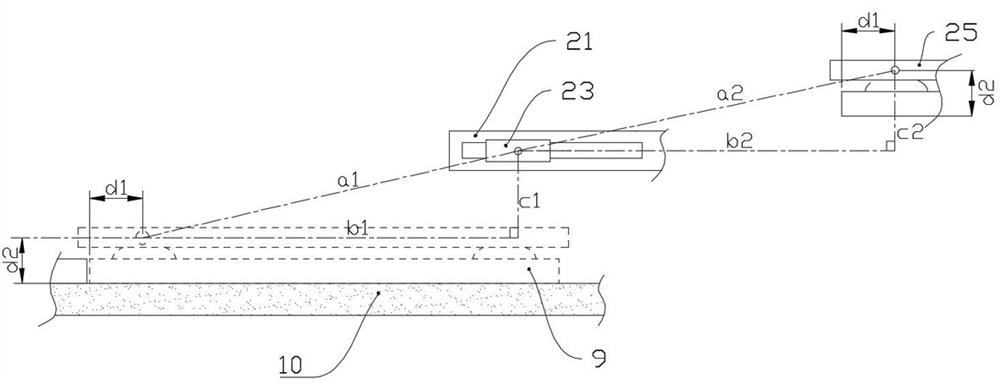

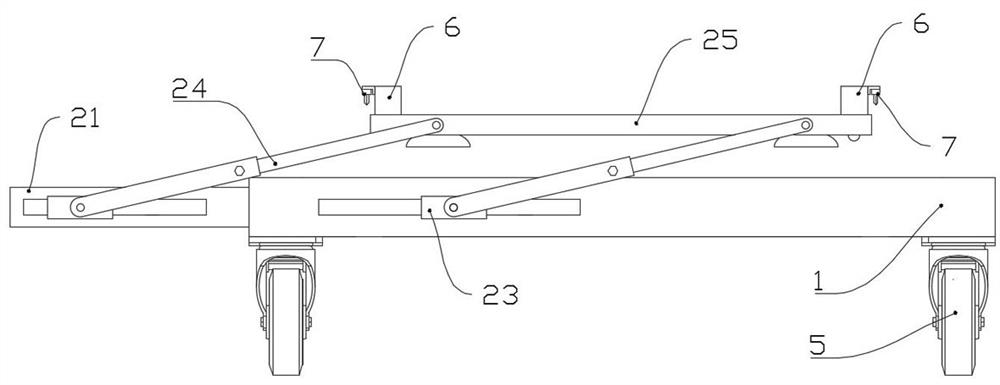

[0029] This embodiment is an automatic tile laying trolley, including a vehicle frame 1 and a gripping mechanism for placing tiles 9 to the laying position; the gripping mechanism includes a horizontally arranged upper suction plate 25 and two pull rods 21, The lower plane of the upper suction plate 25 is provided with several suction cups 26 for sucking the ceramic tiles 9, and the drawing rod 21 is horizontally drawable and installed on opposite sides of the vehicle frame 1;

[0030] The pull rod 21 and the vehicle frame 1 on the corresponding side are provided with chute 22 , and a motor I 23 is adjustablely installed in each chute 22 . The specific structure is that a slide block is arranged in the chute 22, the motor I23 is fixed on the slide block, and a knob bolt is arranged on the slide block to adjust the position of the slide block. The structure is simple, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com