Crown block steel wire rope replacing method

A replacement method and steel wire rope technology, which is applied in the direction of load hanging components, hoisting devices, transportation and packaging, etc., can solve the problems of high labor intensity, low efficiency of steel wire ropes, and many operators, so as to achieve low labor intensity and avoid replacing new ones. Wire rope, the effect of short working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

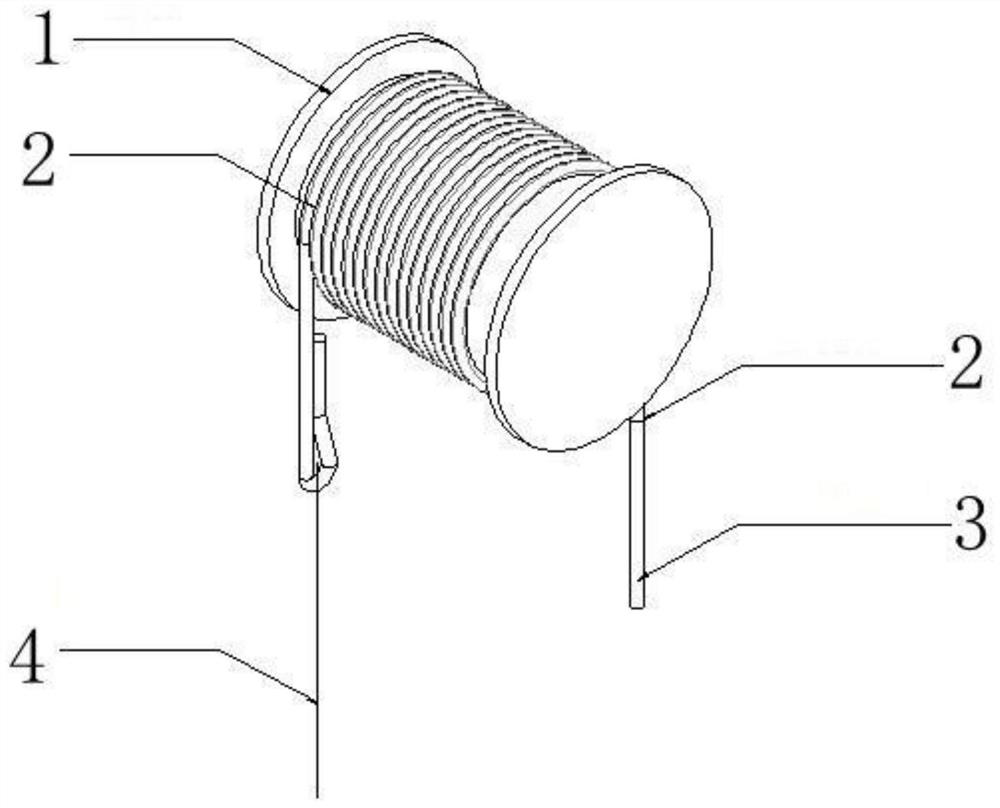

[0028] Such as figure 1 As shown, a method for replacing the steel wire rope of a crane, the specific steps are as follows,

[0029] Release the lifting limit of reel 1, so that the rotation of reel 1 is not restricted by the lifting limit;

[0030] Cut the connection between the old wire rope 2 and the device above or below the reel 1, start the reel 1, and continuously release the old wire rope 2 until the last layer of the old wire rope 2 on the reel 1 is left, so that there are more turns left on the reel 1 Number of old wire rope 2, stop drum 1;

[0031] Cutting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com