Liquid seasoning packaging bottle facilitating food hygiene

A food hygiene and condiment technology, applied in the field of packaging bottles, can solve the problems of food hygiene safety hazards, liquid condiment odors are volatile, etc., to achieve the effect of eliminating potential safety hazards and preventing odor volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

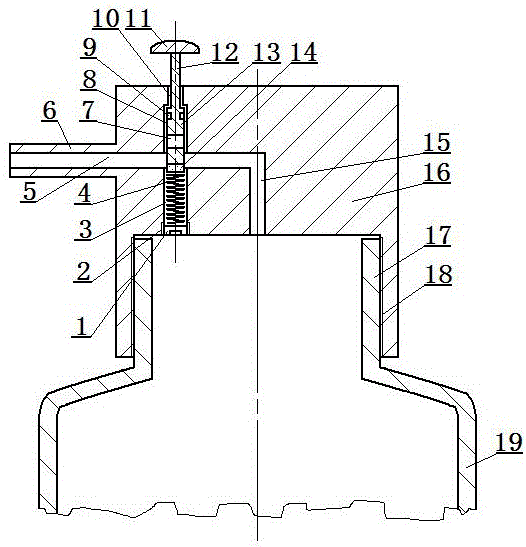

[0018] Example: such as figure 1 As shown, design and manufacture a kind of liquid condiment packing bottle that is beneficial to food sanitation, comprise bottle body 19, bottle cap 16 and liquid spout 6, bottle body 19 and bottleneck 17 are integrally formed, the external thread of bottleneck 17 and bottle cap 16 The internal thread one 18 of the inner thread one 18 cooperates to connect, and the liquid outlet nozzle 6 is integrally formed with the bottle cap 16 and communicates in the bottle body 19 by the circular concave hole two 5 and the circular concave hole one 15.

[0019] Main feature of the present invention is: the upper end wall thickness part of circular concave hole 2 5 is provided with circular concave hole 3 8 and connected square hole 10, and the orifice size of square hole 10 is less than the internal diameter of circular concave hole 3 8.

[0020] The lower end wall thickness part of circular concave hole two 5 is provided with the same circular through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com