Medical waste classification treatment equipment

A technology for processing equipment and medical waste, applied in the field of auxiliary medical waste processing equipment, can solve problems such as destruction, waste exposure, and trouble handling waste, and achieve the effects of avoiding odor volatilization, reducing volume, and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

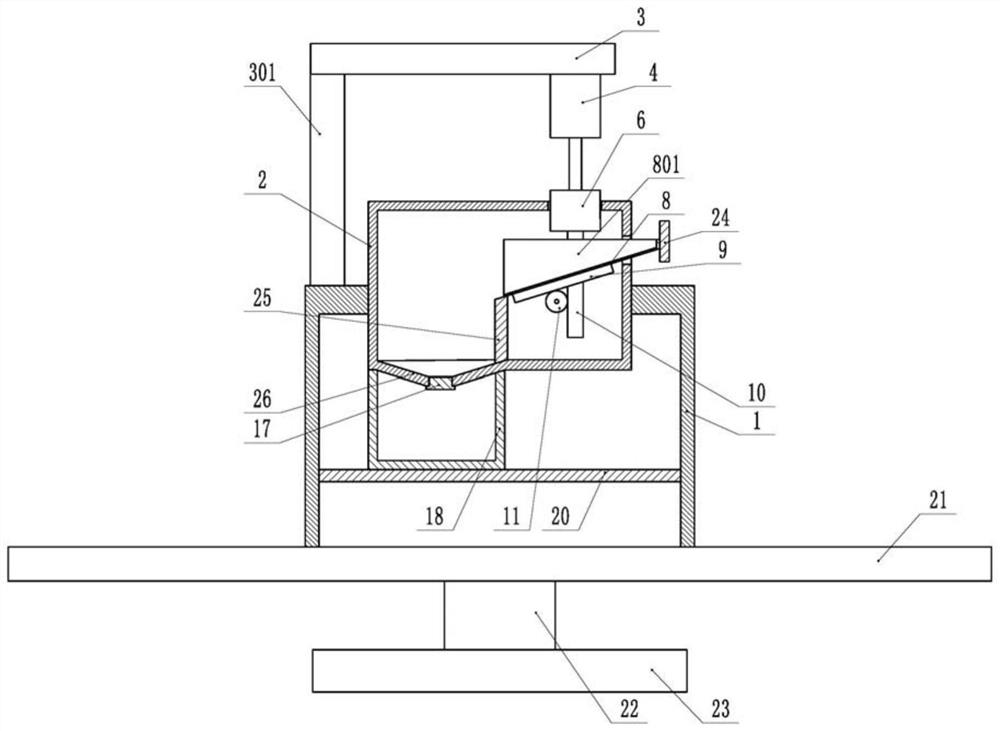

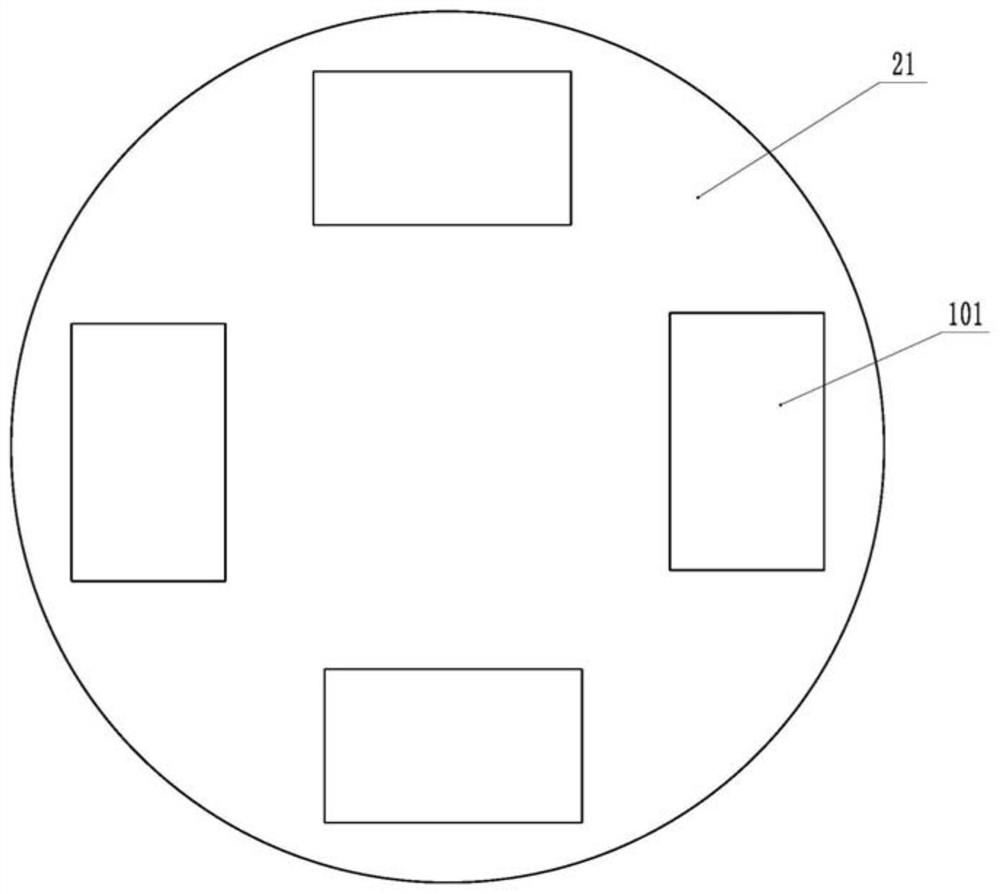

[0031] The embodiment is basically as attached figure 1 Shown: a kind of medical waste sorting processing equipment, including a plurality of waste collectors for sorting and collecting garbage, and also includes a support plate 21, a support column 22 and a bottom plate 23, one end of the support column 22 is fixedly connected to the bottom plate 23 by bolts, and The support column 22 and the base plate 23 are mutually vertically arranged, and the other end of the support column 22 is connected with the support plate 21 through bearing rotation, and the garbage container in the present embodiment is provided with four, as figure 2 As shown, four garbage containers are evenly distributed on the support plate 21 top.

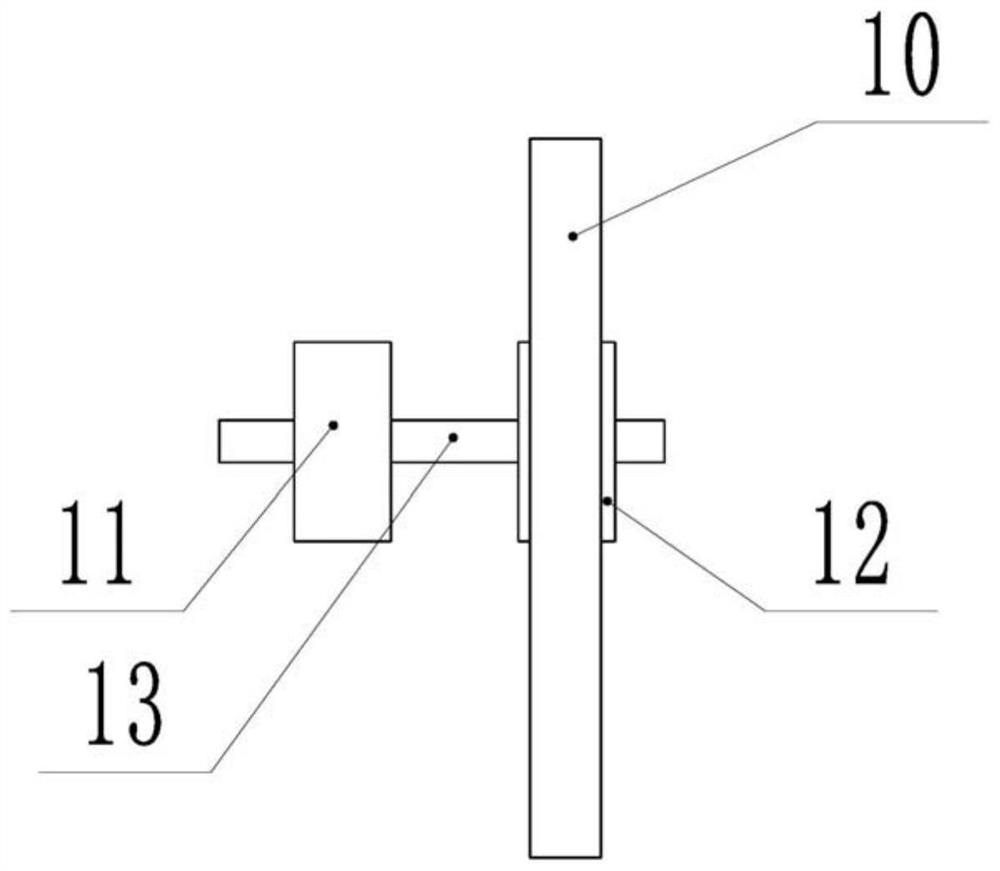

[0032] Such as figure 1 As shown, the garbage collectors in this embodiment all include a workbench 1, and the bottom end of the workbench 1 is fixedly connected to the support plate 21 by bolts. A garbage disposal box 2 is welded and fixed on the workbench 1,...

Embodiment 2

[0044] Such as Figure 4 As shown, a kind of medical waste sorting and processing equipment differs from Embodiment 1 in that: in this embodiment, two crushing teeth 14 are rotatably connected between the two baffle plates 801, and the two crushing teeth 14 mesh with each other to dispose of waste. To crush, the motor can drive the crushing teeth 14 to rotate, thereby crushing the rubbish.

[0045] In this embodiment, the rubbish can be crushed into the rubbish disposal box 2 more smoothly, and the crushed rubbish can be collected more easily, the volume of the rubbish can be reduced, and the capacity of the rubbish disposal bin 2 can be fully utilized.

Embodiment 3

[0047] Such as Figure 5 As shown, a kind of medical waste sorting treatment equipment differs from Embodiment 1 in that: the side of the material guide plate 8 away from the sliding hole is provided with a crushing unit and a power unit, and the power unit includes a second cylinder 5, the second cylinder 5 The cylinder body is fixed with the mounting plate 3 by bolts, and the output shaft of the second cylinder 5 is fixed with a second connecting block 7 by bolts, and the second connecting block 7 is vertically slidably matched with the top of the garbage disposal box 2, and the top of the garbage disposal box 2 The top is provided with a through hole for the second connecting block 7 to penetrate, and there is a gap of 1 mm between the second connecting block 7 and the through hole. The second connecting block 7 can seal the through hole to a certain extent, reducing the The distribution of the garbage smell in the small garbage disposal box 2.

[0048] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com