Backlight module

A technology of backlight module and light source, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of image difference and brightness uniformity, and achieve the effect of improving brightness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

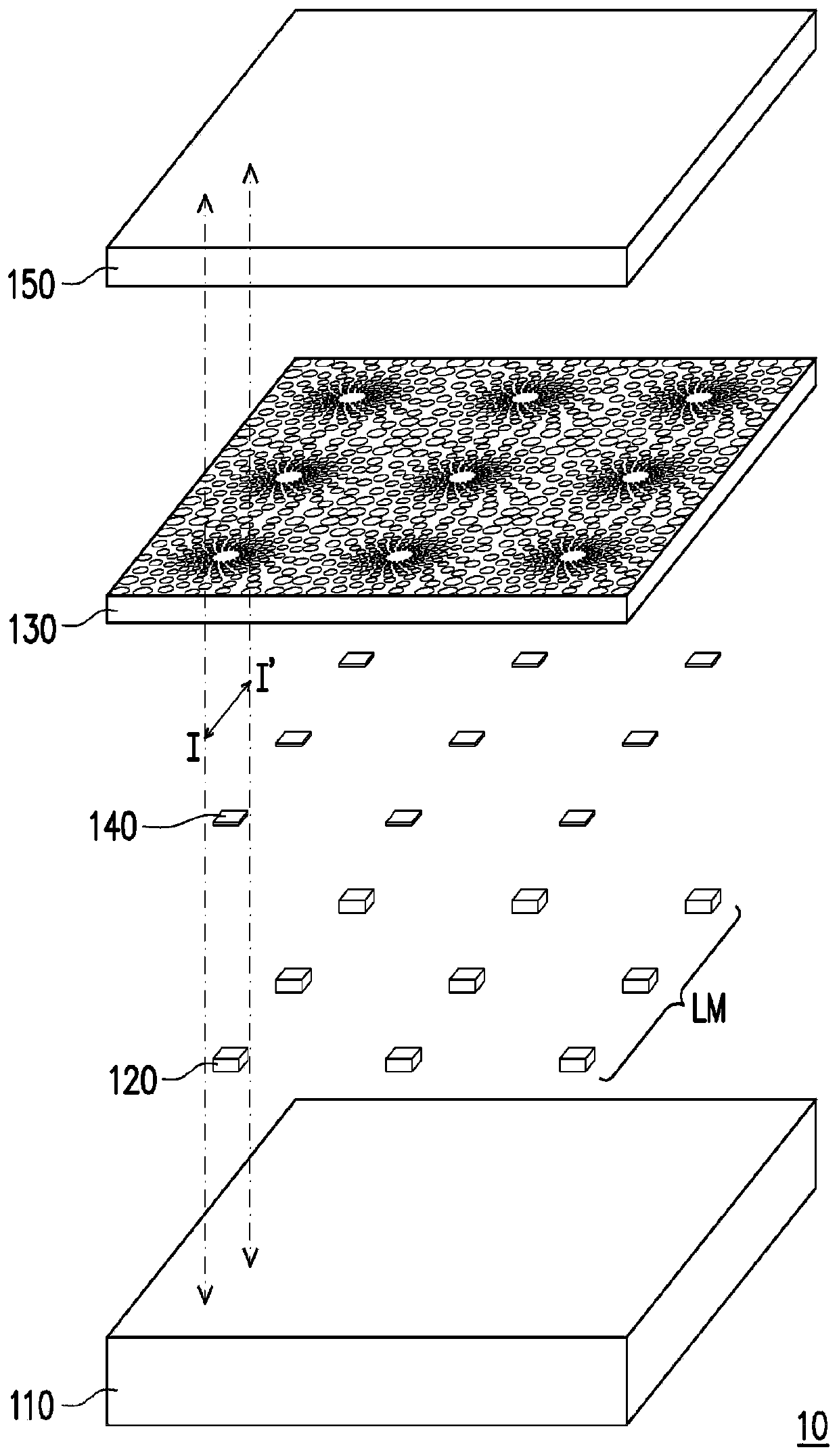

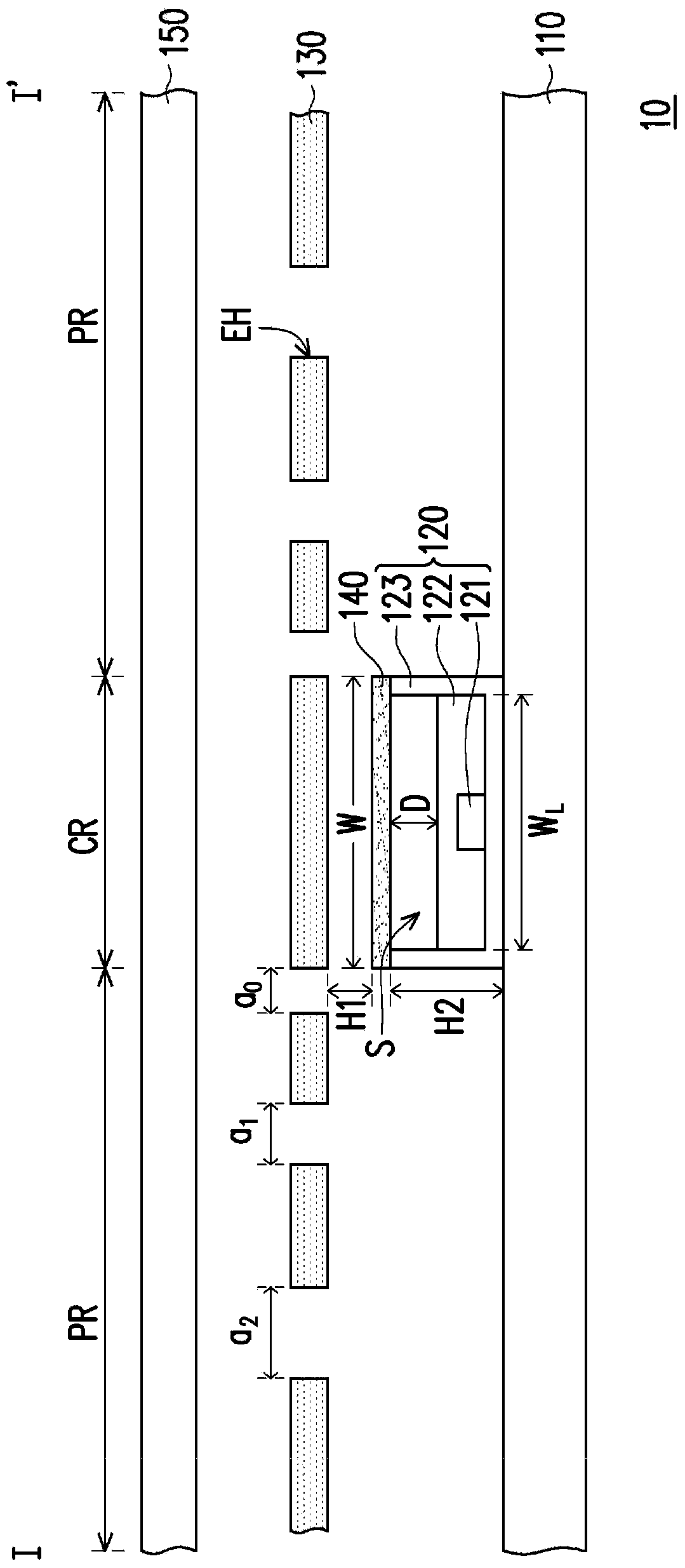

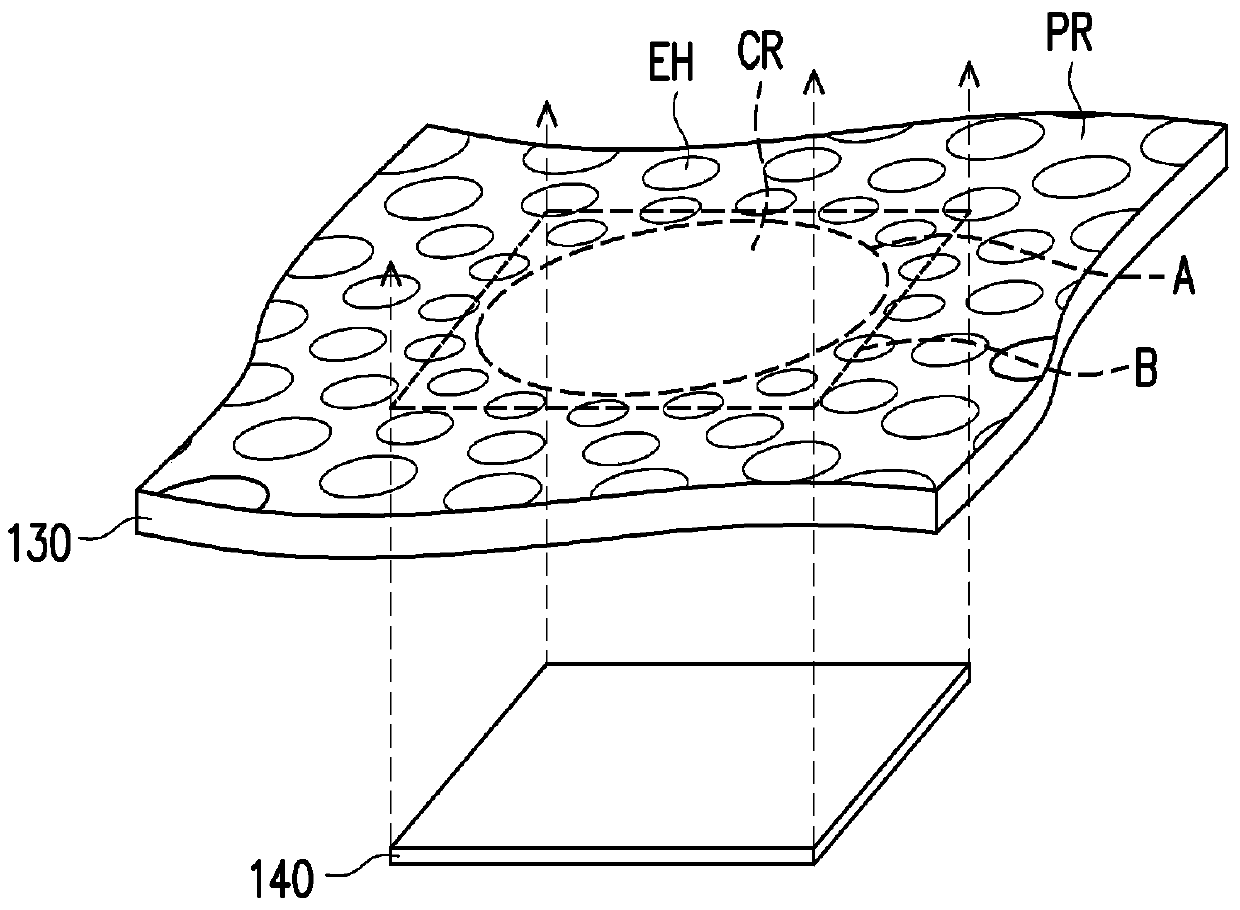

[0064] figure 1 is an exploded schematic diagram of a light source module according to an embodiment of the present invention. Figure 2A for figure 1 The schematic cross-sectional view of the light source module along the section line I-I'. Figure 2B for figure 1 Exploded schematic diagram of the porous optical film and the wavelength conversion optical layer of the light source module. Please also refer to figure 1 as well as Figure 2A , the backlight module 10 of this embodiment includes a substrate 110 , a light source 120 , a wavelength conversion optical layer 130 and a porous optical film 140 , wherein the backlight module 10 may further include a diffusion film 150 . In this embodiment, a single light source 120 is taken as an example to describe the relative positional relationship of the above-mentioned components. Above, the detailed structure of the light source matrix LM will be explained in the following paragraphs. In addition, the backlight module 10 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com