Machine state recognition method based on oil monitoring technology

A technology for oil monitoring and machine status, applied in character and pattern recognition, instruments, computer parts, etc., can solve problems such as inability to accurately realize clustering and identification of wear monitoring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

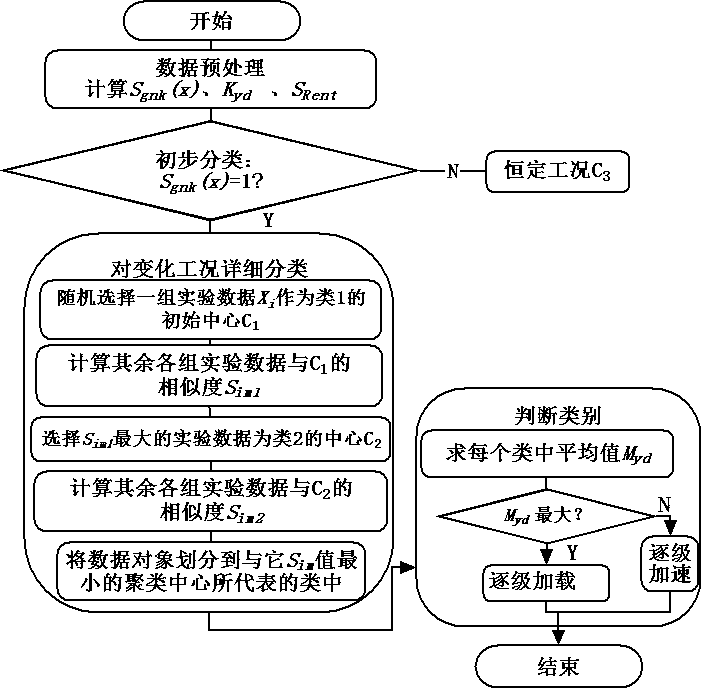

Method used

Image

Examples

Embodiment

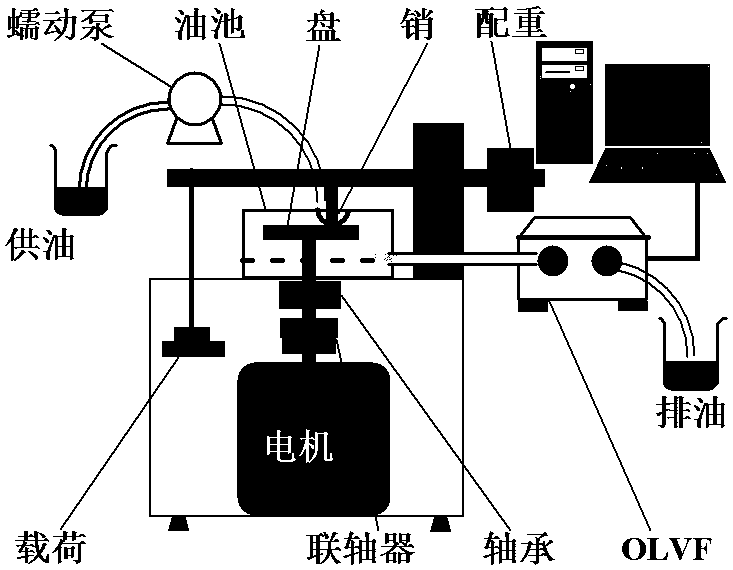

[0147] The wear test was carried out by using a self-made pin-on-disc wear tester. A peristaltic pump is used to supply oil to the friction pair, and OLVF is used to periodically collect lubricating oil samples in the wear oil pool to obtain information on the concentration of abrasive particles in the lubricating oil. The schematic diagram of the test system is as follows: figure 2 shown. The upper sample used in the test is the first air ring of an engine cut into several small sections, and its outer surface is chrome-plated. The sample on the piston ring is clamped on the fixture. The lower test plate used in the test is a gray cast iron plate with a diameter of 60 mm and a thickness of 5 mm. The material is HT250 and the hardness is HV210. The material used for the test disc is close to the real material of the engine.

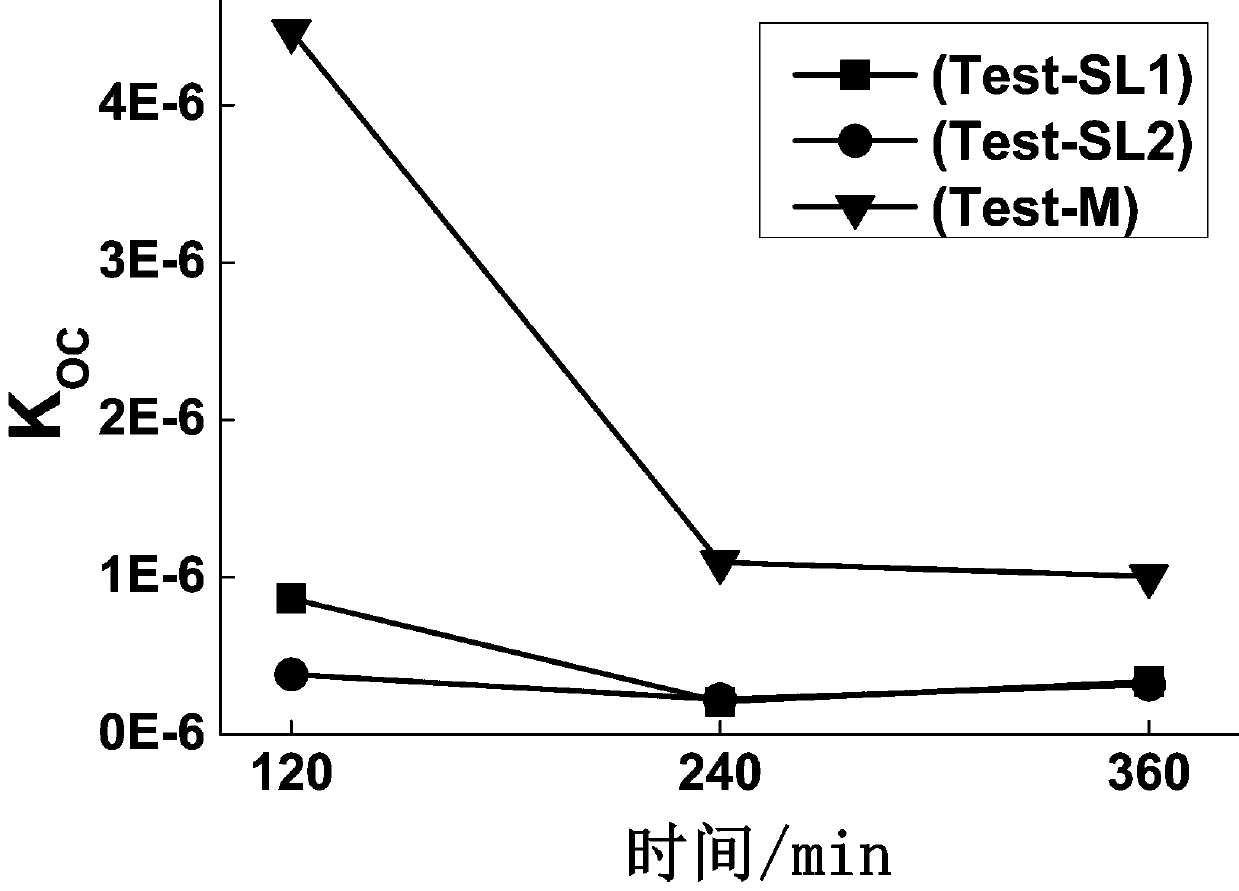

[0148] The OLVF system is used to monitor the concentration of ferromagnetic abrasive particles in the lubricating oil online, and the IPCA value of ...

Embodiment 2

[0164] Example 2: Working condition identification of the engine tribology system

[0165] When the engine works under variable working conditions, the working conditions of typical friction pairs are also changing constantly. Therefore, the cluster analysis method for friction pairs mentioned above is used for the cluster analysis of the working conditions of the OLVF monitoring data of the whole engine.

[0166] Engine bench test and data processing:

[0167] 1) Bench test data

[0168] A four-cylinder gasoline engine was selected for the test, and the thermal shock test was carried out after the running-in process. The OLVF monitoring system was used to monitor the engine wear state. Among them, about 104 hours of engine wear monitoring data are analyzed (such as Figure 7 shown).

[0169] 2) Dynamic sliding window data segmentation

[0170] During the online monitoring process, the sliding window model is periodically updated to segment the continuously collected OLVF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com