Improved halftone projection and model generation method facing 3D printing

A 3D printing and model generation technology, applied in 3D modeling, 3D image processing, instruments, etc., can solve problems such as discrete light and discontinuous projection effects, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

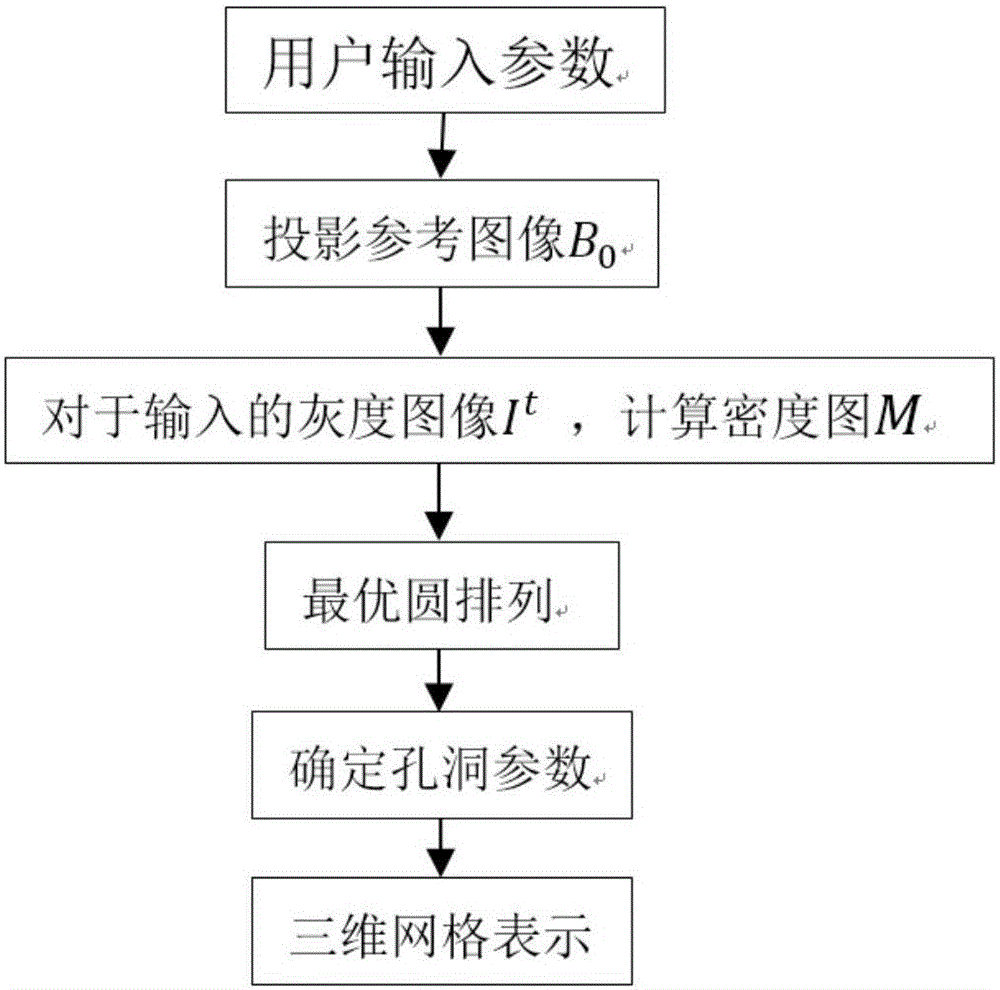

[0053] like figure 1 As shown, a halftone projection and model generation method for 3D printing includes the following steps:

[0054](1) The user specifies parameters such as the 3D model, the projection receiving surface and the position and size range of the light source, and calculates the projection reference image B through the projection simulation method 0 ;

[0055] (2) For any input grayscale image I t , combined with the projected reference image B 0 , calculate a density map M;

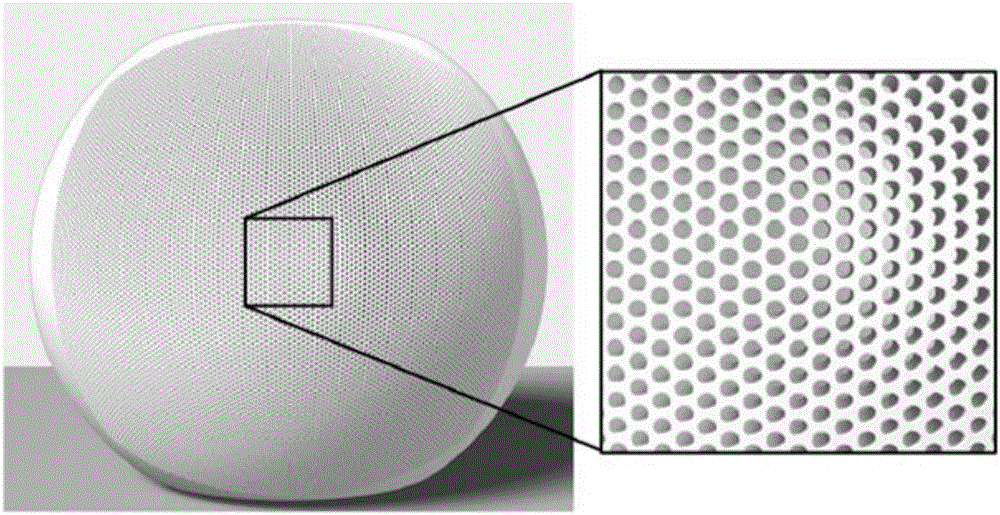

[0056] (3) According to the density map M, the method of Voronoi partition (CCVT) with capacity constraints is used to calculate the optimal circle arrangement;

[0057] (4) According to the arrangement of the circles, corresponding enlarged holes and inclined holes are generated.

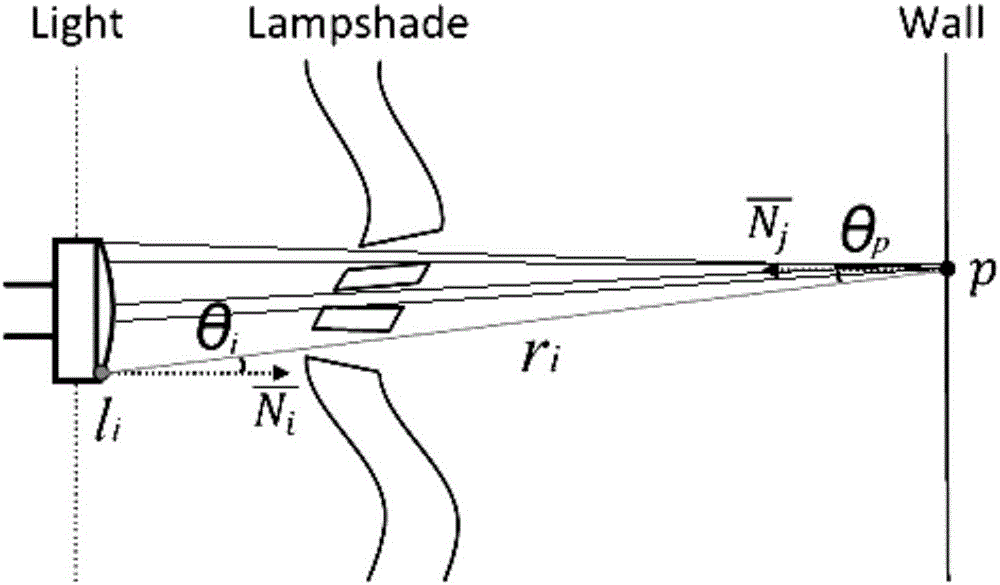

[0058] In said step (1), the projection simulation method specifically includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com