Manufacturing and application method of plastic bathtub

A bathtub and plastic technology, applied in bathtubs, showers, etc., can solve the problems of high cost and large occupied area, and achieve the effect of low cost, small occupied space and low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

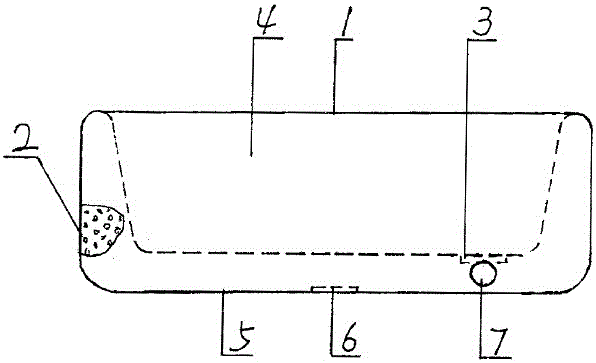

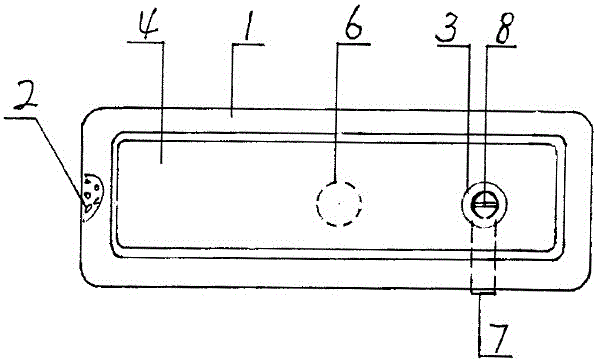

[0011] Such as figure 1 Shown in , 2, a kind of manufacture and use method of plastic type bathtub, makes up for above-mentioned defect with this; This bathtub is connected and formed by shell 1, foam 2 and valve 3; Shell 1 is a plastic casing (with The shell-shaped plate is called the shell), the shell 1 is made of plastic material, and the external shape of the shell 1 after injection molding (referring to the three-dimensional shape of the periphery) is a cuboid with corners; a water tank is arranged in the middle of the shell 1 4. The shape of the sink 4 is the same as that of a traditional bathtub (referring to the kind of cuboid with corners at the corner); the sink 4 is used to drain water for bathing; the bottom of the sink of the shell 1 is provided with a valve 3 for draining water. There is a section of right-angle elbow 7 on the valve 3; the valve 3 and the right-angle elbow 7 are fixed on the shell 1, and the valve 3 and the shell 1 are fixedly connected into one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com