Chemical reaction kettle with adjustable stirring temperature

A chemical reaction and stirring shaft technology, applied in chemical/physical/physical-chemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc. Obviously, the number of settings is limited, etc., to achieve the effect of wide heating range, low cost and fast temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

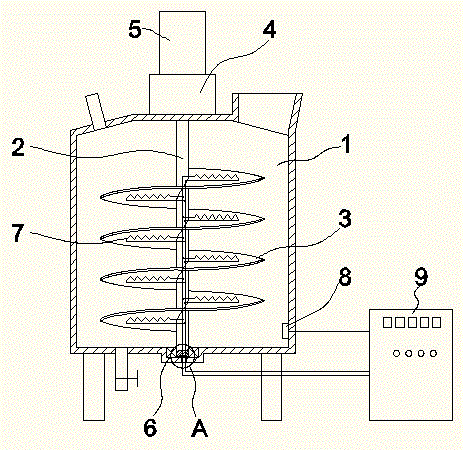

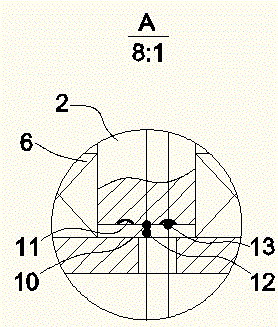

[0015] Such as figure 1 As shown, a chemical reaction kettle with adjustable stirring temperature of the present invention includes a kettle body 1, a stirring shaft 2 is arranged in the center of the interior of the kettle body 1, and a plurality of helical stirring blades are arranged on the stirring shaft 2 3. The upper end of the stirring shaft 2 is connected to the reduction box 4 fixed on the outer top of the kettle body 1, the reduction box 4 is connected to the drive motor 5, and the lower end of the stirring shaft 2 is fixed to the bottom of the kettle body 1 In the bearing 6, the inside of the spiral stirring blade 3 is provided with an electric heater 7, and the electric heater 7 is connected to the positive electrode 10 and the negative electrode 11 at the bottom end of the stirring shaft 2 through wires, and the positive electrode 10 is in the form of a point shape, located at the center of the bottom end of the stirring shaft 2, the negative electrode 11 is in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com