Rotational structure of mechanical arm for automatic lathe

A technology of mechanical arm and rotating structure, applied in the direction of manipulator, program-controlled manipulator, injection device, etc., can solve the problems of easy fatigue, waste of manpower, easy to soil hands, etc., and achieve high economic benefits, manpower saving, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

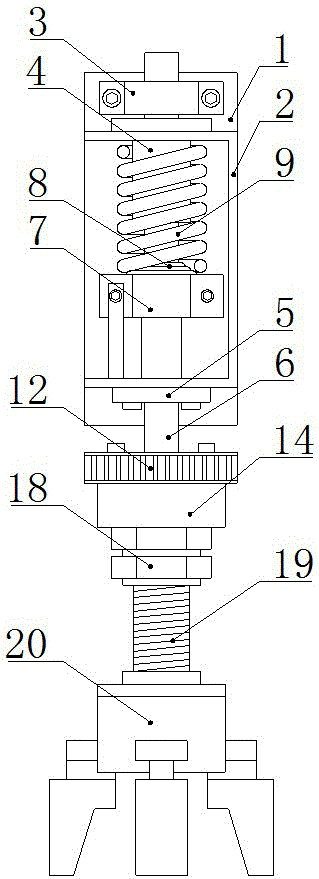

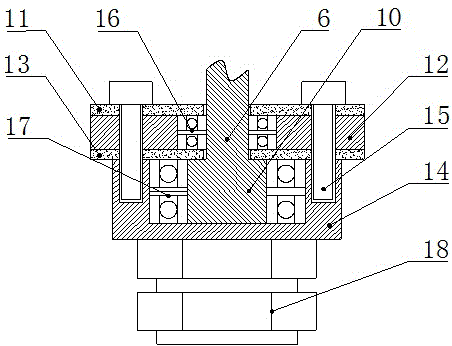

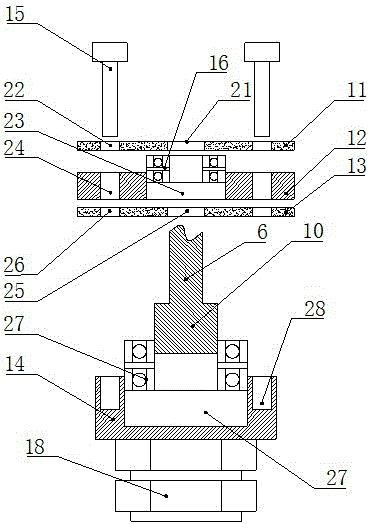

[0018] Such as Figure 1-3 Shown, the rotating structure of the mechanical arm of a kind of automatic lathe, it comprises fixed plate A1 and the fixed plate B2 that is welded on the fixed plate A1, the upper part of described fixed plate A1 is fixed with bearing block 3 by hexagonal bolt, described The upper end of the fixed plate B2 is fixed with a linear bearing A4, the lower end of the fixed plate B2 is fixed with a linear bearing B5, the linear bearing A4 and the linear bearing B5 pass through a rotating shaft 6, and one end of the rotating shaft 6 passes through the bearing seat 3. The upper side of the lower end of the fixed plate B2 is fixed with a fixed shaft block 7 through a hexagonal bolt, and a rubber gasket 8 is arranged between the fixed shaft block 7 and the linear bearing A4, and a buffer spring is arranged on the outer circumference of the linear bearing A4 9. The lower end of the rotating shaft 6 is provided with a protrusion 10, and the lower part of the rot...

Embodiment 2

[0021] Such as Figure 1-3 Shown, the rotating structure of the mechanical arm of a kind of automatic lathe, it comprises fixed plate A1 and the fixed plate B2 that is welded on the fixed plate A1, the upper part of described fixed plate A1 is fixed with bearing block 3 by hexagonal bolt, described The upper end of the fixed plate B2 is fixed with a linear bearing A4, the lower end of the fixed plate B2 is fixed with a linear bearing B5, the linear bearing A4 and the linear bearing B5 pass through a rotating shaft 6, and one end of the rotating shaft 6 passes through the bearing seat 3. The upper side of the lower end of the fixed plate B2 is fixed with a fixed shaft block 7 through a hexagonal bolt, and a rubber gasket 8 is arranged between the fixed shaft block 7 and the linear bearing A4, and a buffer spring is arranged on the outer circumference of the linear bearing A4 9. The lower end of the rotating shaft 6 is provided with a protrusion 10, and the lower part of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com