Power online monitoring system of rotation output equipment

A technology of rotating output and monitoring system, applied in power metering, measuring device, torque metering and other directions, can solve the problems of large error of monitorable parameters, large error of detection parameters, and inability to detect parameters, and achieves light and simple structure and high detection accuracy. High, large measuring range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

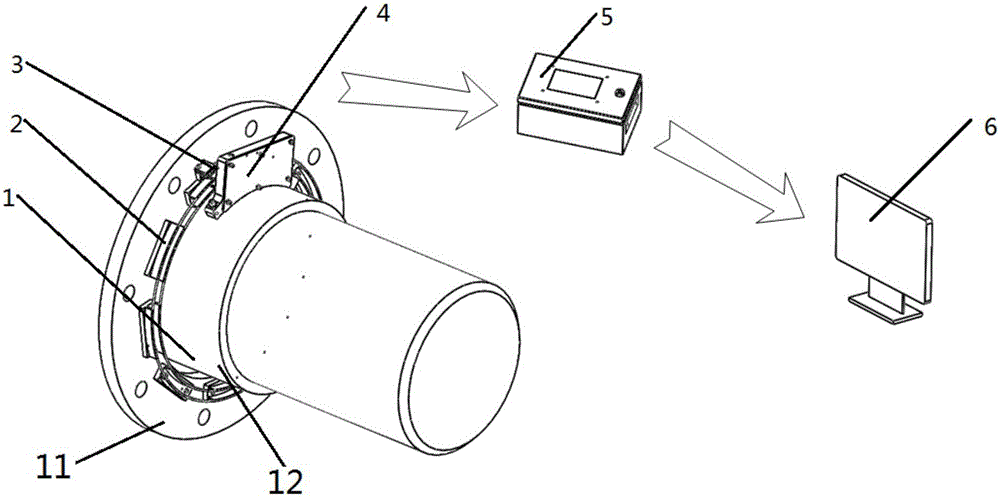

[0019] Such as figure 1 As shown, an online power monitoring system for a rotary output device includes a rotary output device 1, a non-contact power supply module 2, a rotational speed signal measurement module 3, a torque signal measurement module 4, a field instrument display terminal 5 and a remote data receiving terminal 6 ,in:

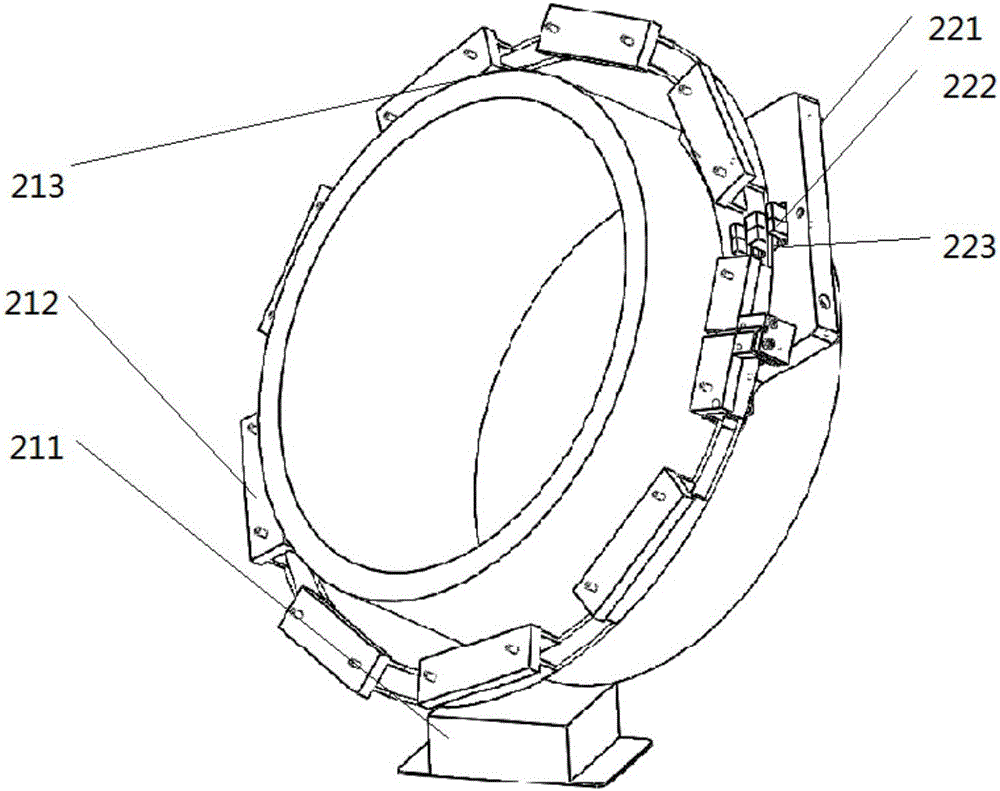

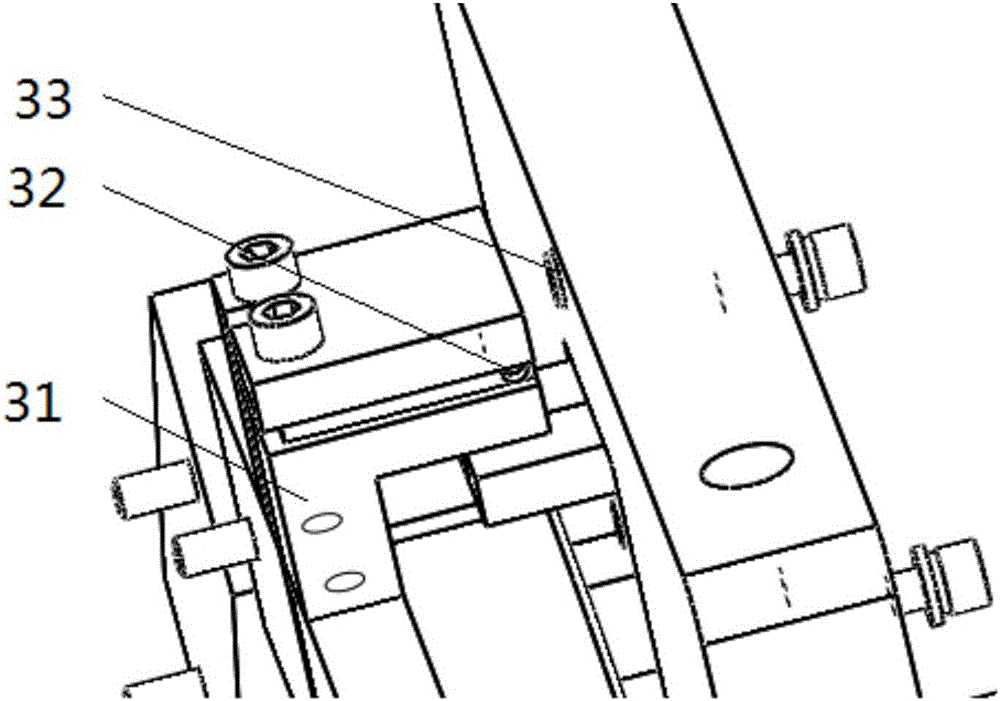

[0020] The rotary output device 1 includes the output outer wall 11 of the prohibiting part and the output shaft 12 of the rotating part. The torque signal measurement module 4 includes a follow-up measurement module 41 and a torque signal acquisition box 42. The signal acquisition box is located inside the follow-up measurement module and is fixed on the On the output shaft 12, the non-contact power supply secondary side 22 is also fixedly installed on the follow-up measurement module 41. The non-contact power supply primary side 21 and the secondary side adopt a loose coupling connection, and the primary side is fixed on the reducer at a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com