Intelligent vehicle realizing flexible conveying

A flexible transmission and intelligent vehicle technology, applied in two-dimensional position/channel control, vehicle position/route/height control, non-electric variable control, etc., can solve complex, multi-production space, fixed line conveyor line adjustment Inconvenience and other issues, to achieve the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

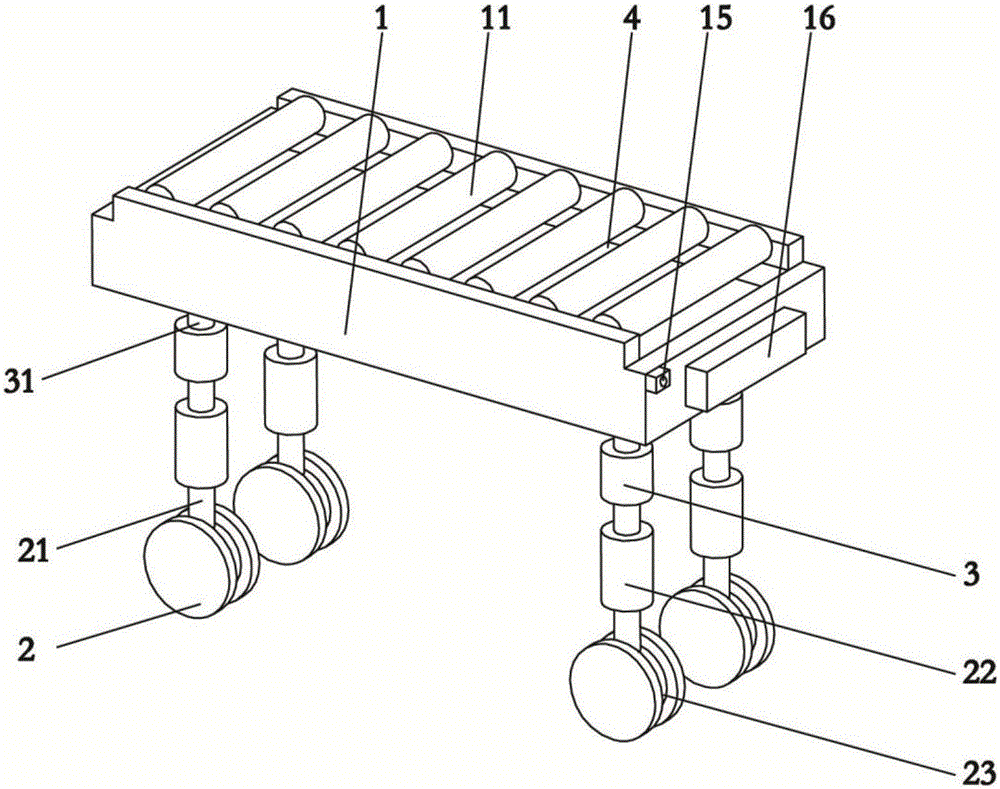

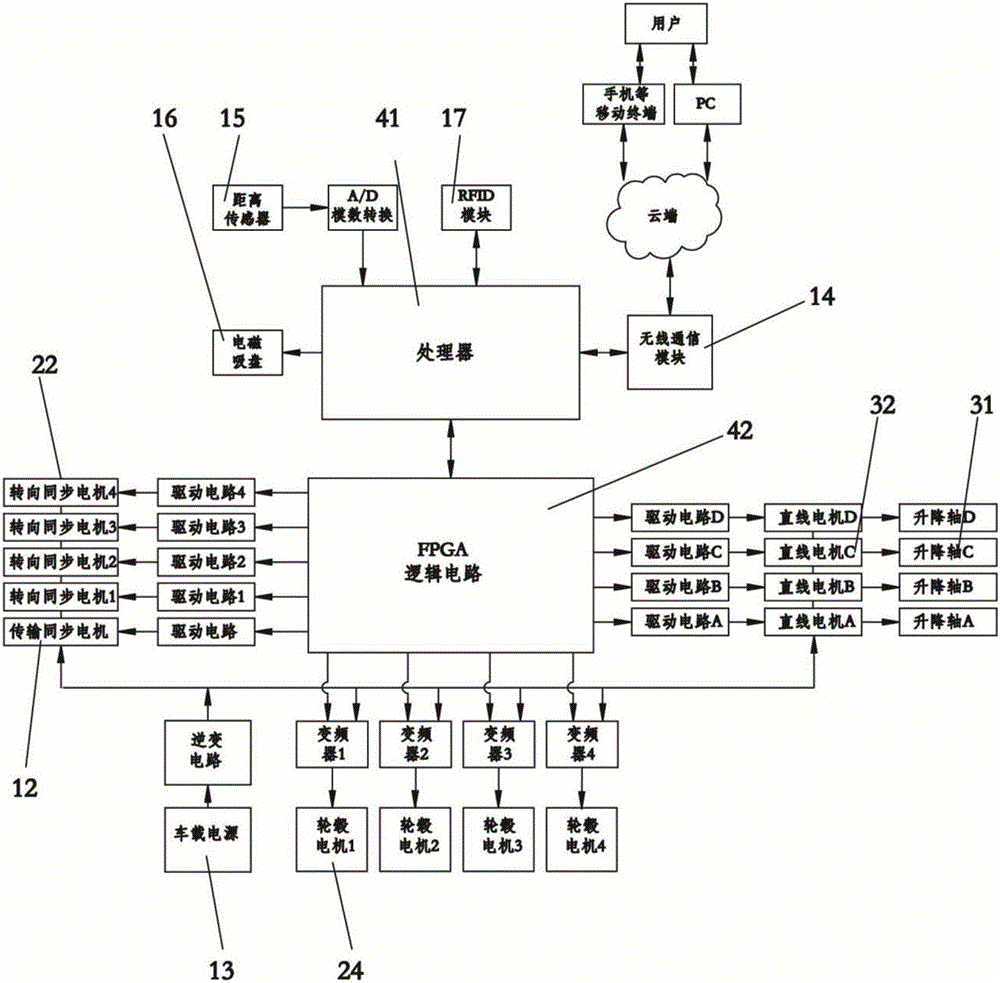

[0016] Such as figure 1 As shown, a smart car with flexible transmission according to the present invention includes a transmission platform 1, and N horizontally rotatable rollers 11 are arranged on the transmission platform 1, where N is an integer greater than 4, and the bottom of the transmission platform 1 A displacement mechanism 2 is provided, and a lifting adjustment device 3 is connected between the displacement mechanism 2 and the transmission platform 1; a transmission synchronous motor 12, an on-board power supply 13 and a main control device 4 are arranged in the transmission platform 1, and the transmission synchronous motor 12 is connected with the transmission platform 1 respectively. N rollers 11 are connected by transmission, N rollers 11 rotate on the transmission platform 1 in the same direction and at the same spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com