Dry-burning preventing kettle coupler with fusing

A coupler and anti-dry technology, applied to electrical components, electric switches, circuits, etc., can solve the problems of threatening the life and property safety of users, difficulty in ensuring safety, and affecting service life, etc., achieving simple and practical structure and improving safety Sexuality, cost-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

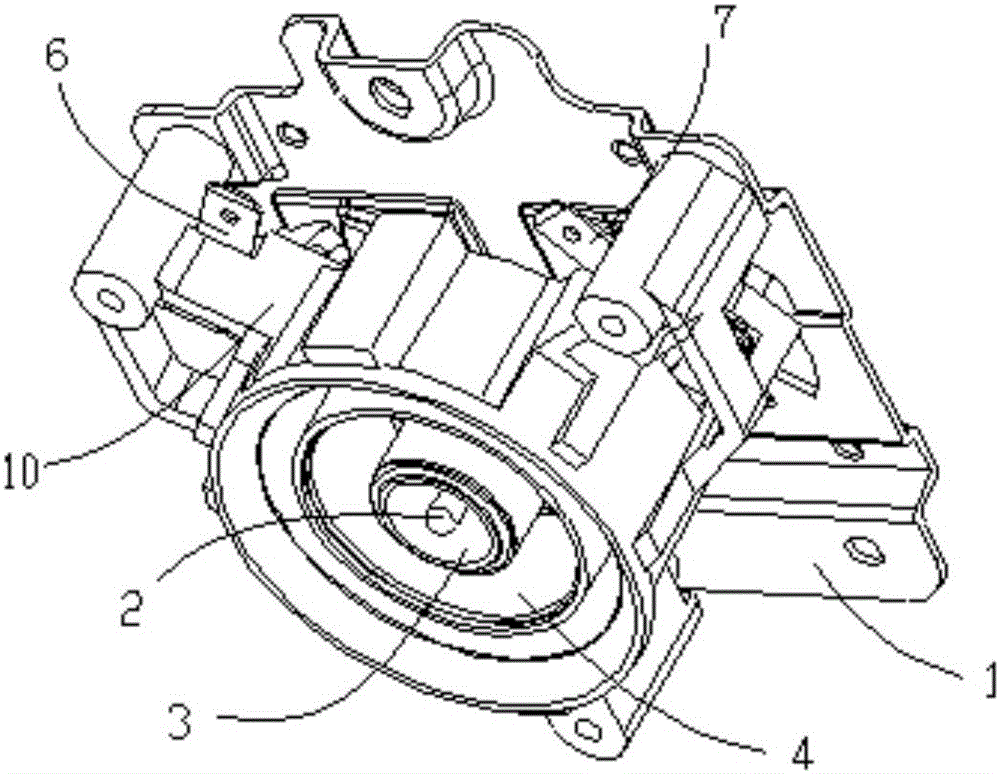

[0036] see Figure 1 to Figure 3 , the present invention provides a fuse-proof anti-dry kettle coupler, including a panel 1, a central rod 2, a first terminal ring 3, a second terminal ring 4, a connecting piece 5, a first terminal 6, and a second terminal 7 , bimetal disc 8, ceramic rod 9, fuse device and bracket body 10;

[0037] The central rod 2 stands at the center of the panel 1, the first terminal ring 3 and the second terminal ring 4 are ring-shaped and respectively surround the periphery of the central rod 2 inside and outside; the bracket body 10 is connected and fixed to the panel 1, and the first terminal 6 and the The second terminals 7 are respectively fixedly installed on the support body 10, and the ends of the first terminal 6 and the second terminal 7 are respectively fixedly provided with a fixed contact; The two terminal rings 4 are electrically connected, and the other end of the connecting piece 5 is fixedly provided with a moving contact, and the two mo...

Embodiment 2

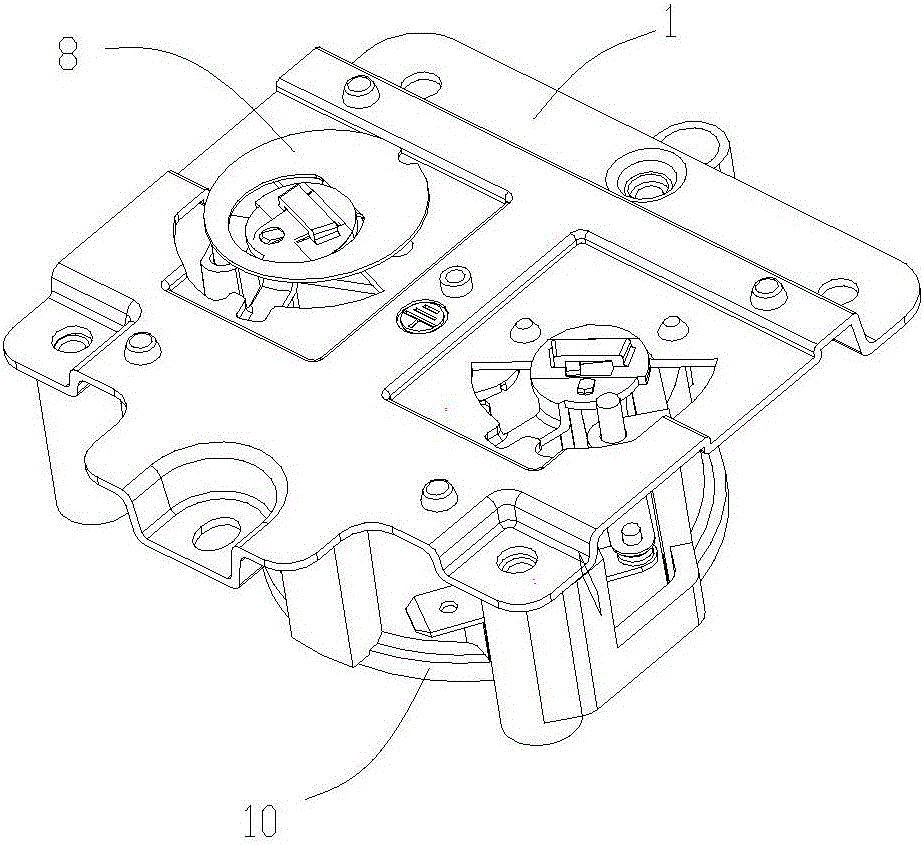

[0046] The only difference between this embodiment and Embodiment 1 is that this embodiment adopts the design of two bimetallic discs 8, and the two electrodes composed of the first terminal ring 3 and the second terminal ring 4 are simultaneously applied with bimetallic discs. Chip 8 self-resetting anti-dry burning power-off protection.

[0047] see Figure 4 Specifically, as a preference, the bimetallic disc 8 is provided with two pieces, which are respectively arranged directly above the two connecting pieces 5, and the two connecting pieces 5 and the two bimetallic discs 8 are respectively provided with A ceramic rod 9; one of the connecting pieces 5 is also connected with the fuse device.

[0048] Two bimetallic discs 8 act on the two electrodes respectively, the principle of which is to make the ceramic rod 9 protrude from the connecting piece 5 when the heat jumps, so that the fixed contact is disconnected from the movable contact. The fuse device independently perfor...

Embodiment 3

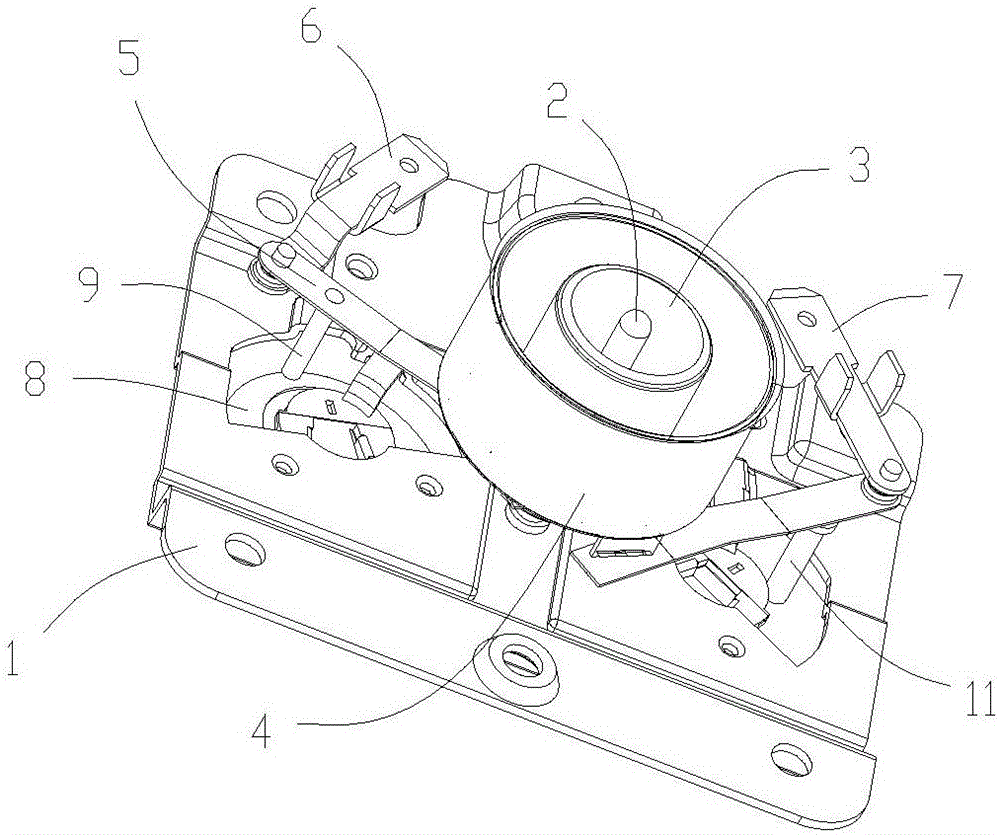

[0053] see Figure 5 , The only difference between this embodiment and Embodiment 1 and Embodiment 2 is that a heat conduction extension 16 is added for direct heat conduction, which accelerates the reaction speed of the fuse rod 11 and improves the safety of the product.

[0054] Preferably, the top of the fuse rod 11 is provided with a heat conduction extension 16 extending upwards for connection with external heat conduction; the heat conduction extension 16 extends upwards and is exposed on the surface of the panel 1 . Then, when the present invention is installed on the bottom of the heating plate of the kettle, the heat conduction extension 16 can directly contact with the heating plate, and the heat of the heating plate will be directly transmitted to the fuse rod 11, so that the fuse rod 11 can be more rapid, sensitive, Respond directly, greatly improving security.

[0055] This structure is further added on the basis of the solution of Embodiment 1 or Embodiment 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com