Nasal rinse with valve actuatable by breathing air

A cleanser and nasal cavity technology, applied in the field of nasal cleansers, can solve the problems of passive transfer or active inhalation, harm to users, user discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

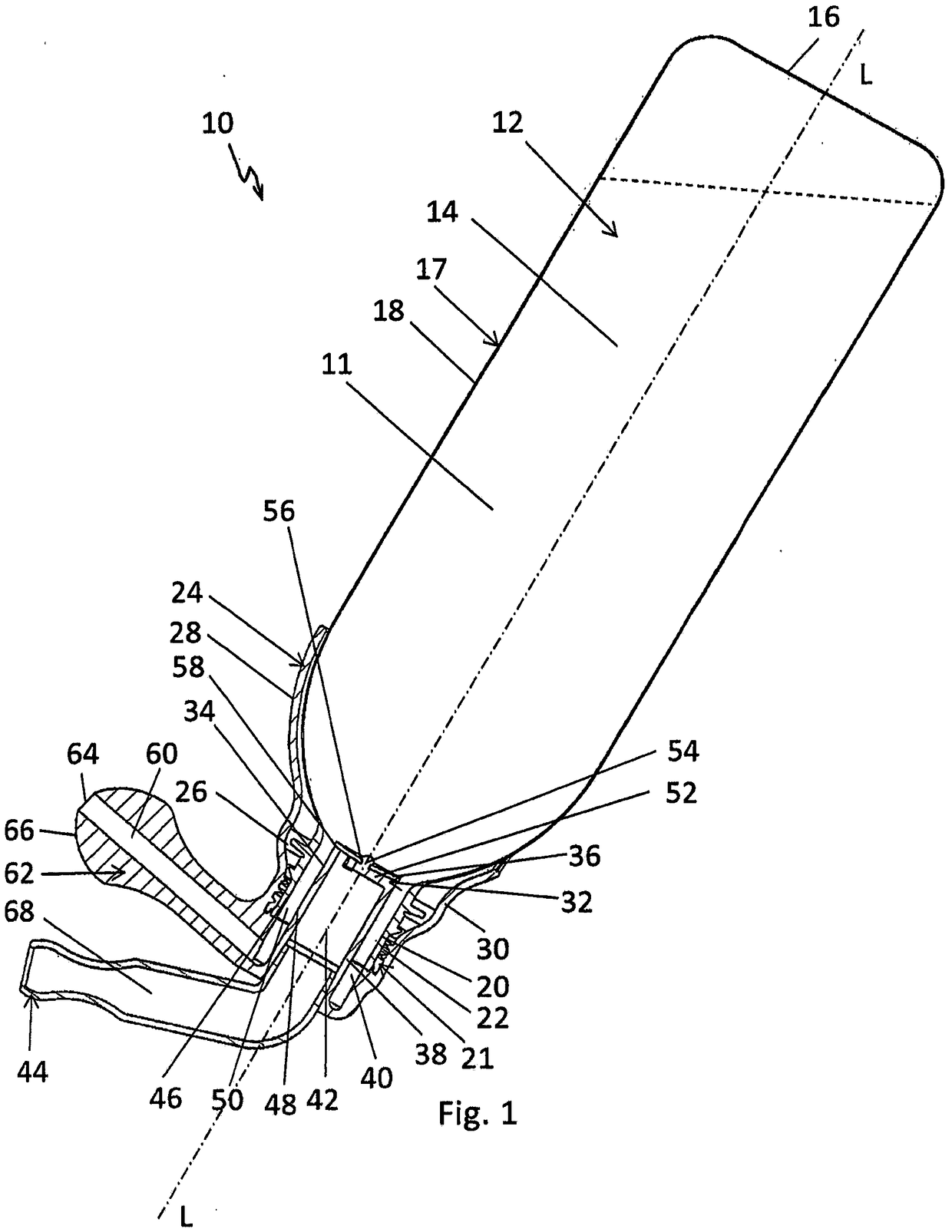

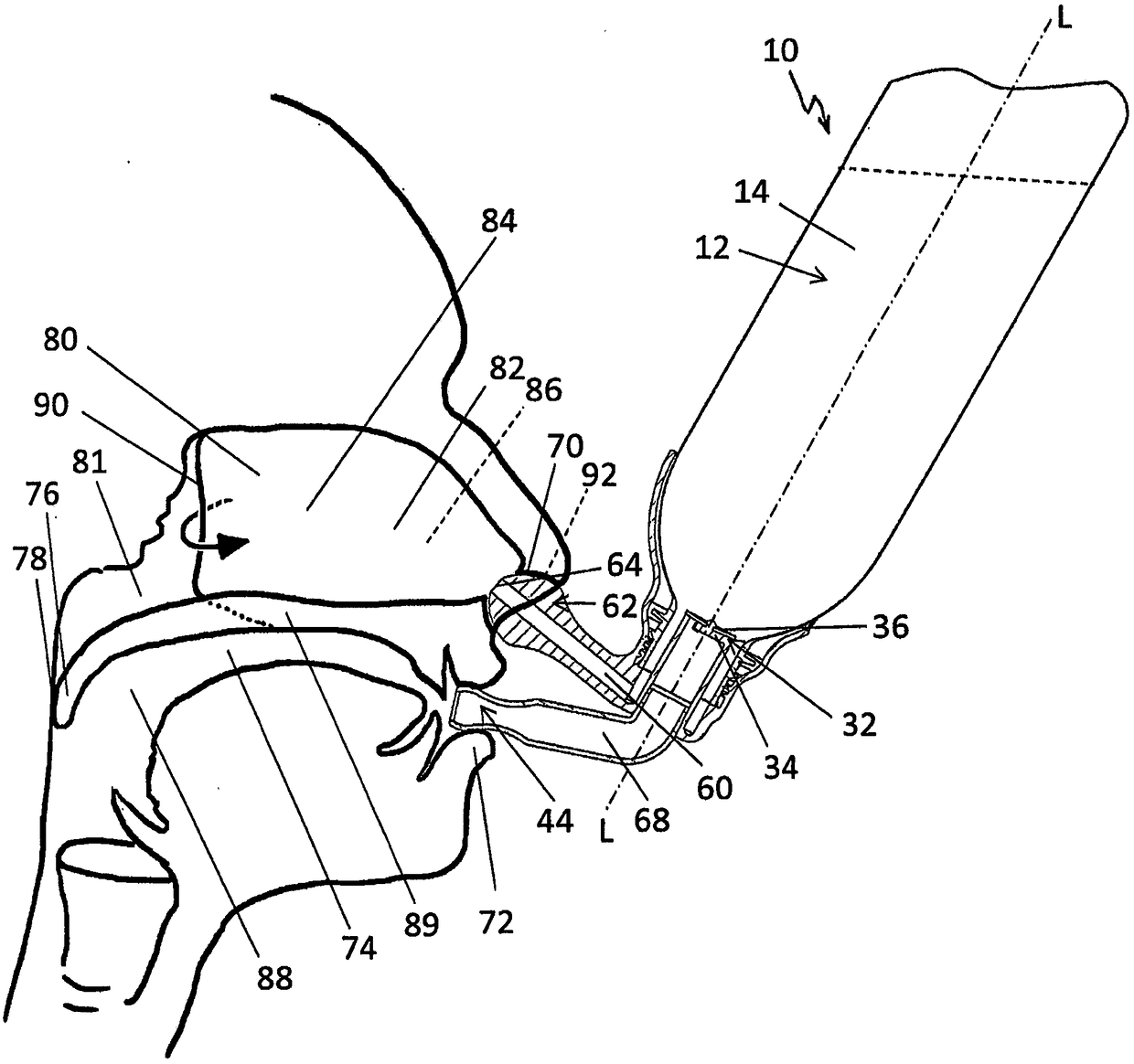

[0042] According to the nasal cavity washing device 10 of the present invention, such as figure 1 The first embodiment shown is shown in the use position (inverted position) as shown in the figure, ie turned over 180°.

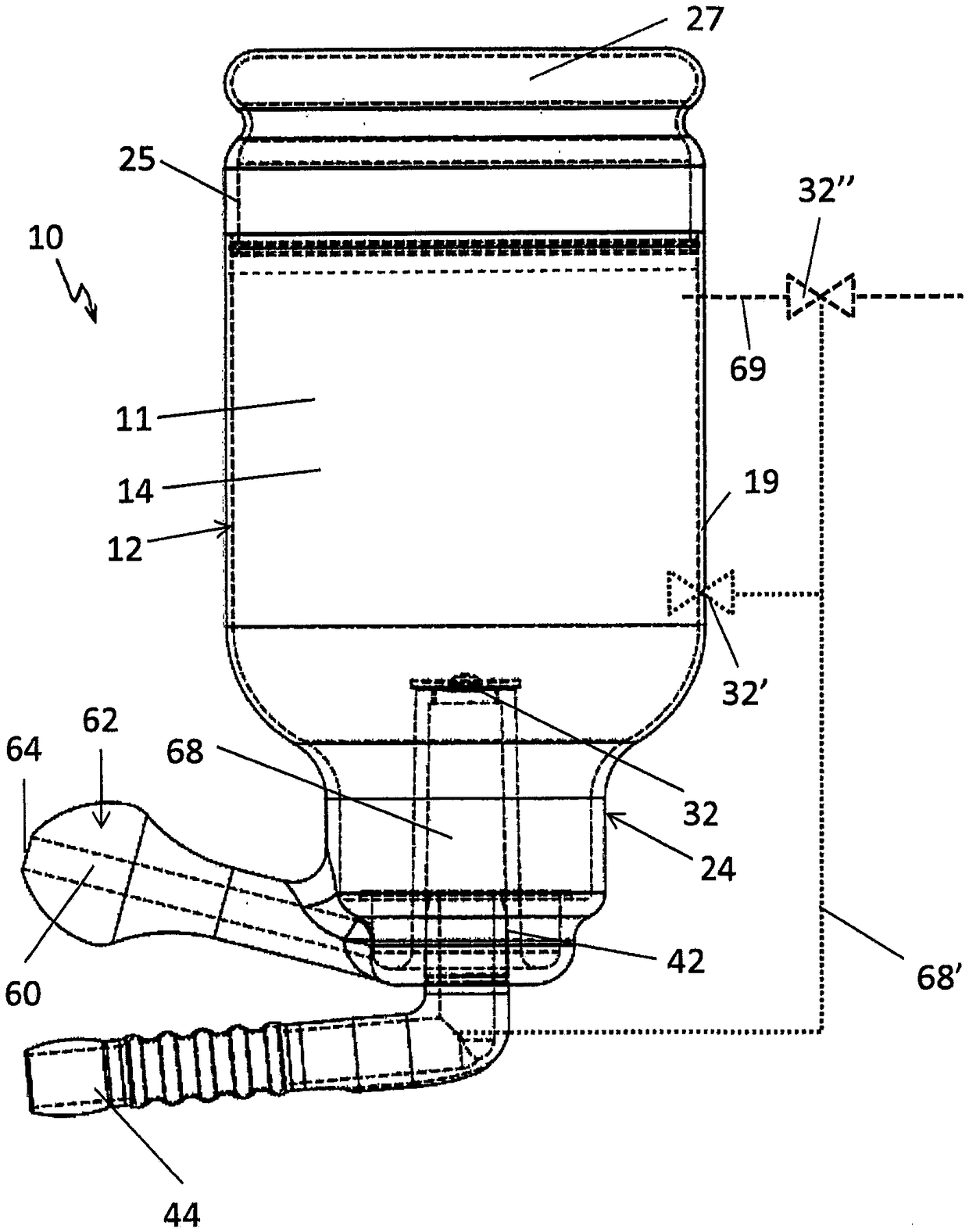

[0043] The nasal rinse 10 has an irrigation liquid 14 in the interior 11 of a separate container part 12 and it is fitted with a separate cap part 24 . In this embodiment, the container part 12 and the lid part 24 are separate components which are detachably fastened together by means of a threaded connection 21 .

[0044] Depending on the application, the container part 12 can have, for example, a filling volume of approximately 100 ml to approximately 500 ml and is, for example, a bottle 12 ′ with a base 16 and a narrowed neck 20 connected to a belly 18 . The maximum filling volume of the container part 12 is especially aimed at the ease of handling of the nasal irrigation device 10 of the present invention with regard to practical use, ie the filling volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com