A compact filling food forming machine

A compact, forming machine technology, applied in the field of food processing, to achieve the effect of reducing quantity, reducing volume and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

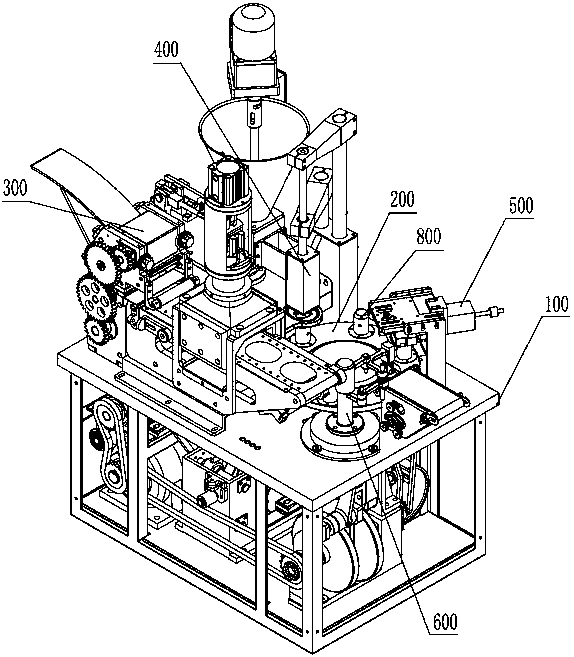

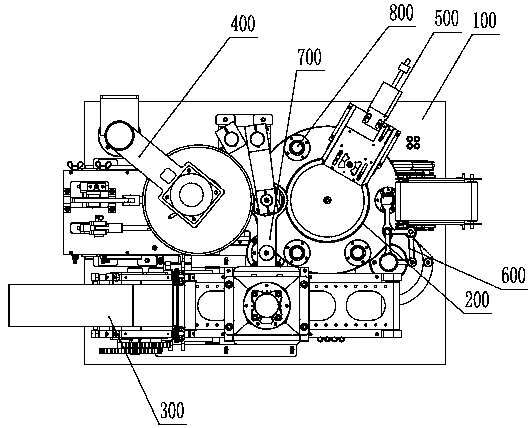

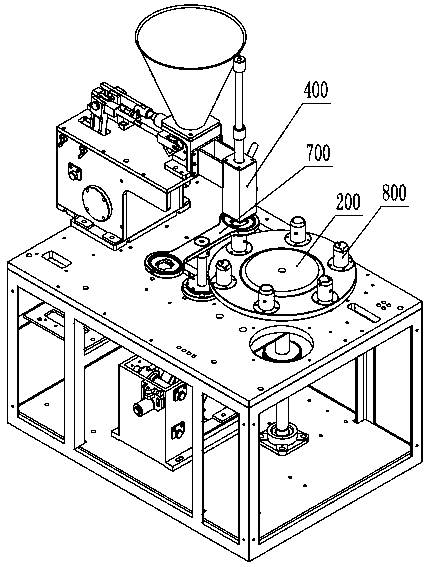

[0031] A compact stuffed food forming machine includes a frame 100 and a station turntable 200 located on the frame 100, a leather making device 300, a filling device 400, a pressing device 500 and an outlet are respectively arranged around the station turntable 200. Material device 600, the leather making device 300 is a skin making station, the stuffing device 400 is a filling station, the pressing device 500 is a pressing station, and the discharging device 600 is a discharging station; A split forming mold is also arranged on the frame 100 , and the split forming mold includes a rotating skin plate 700 and a mold cup 800 which are independent of each other. The horizontal position of the rotary skin grafting plate 700 is higher than that of the station turntable 200 , and the rotary leather grafting plate 700 is located between the leather making device 300 and the station turntable 200 . There is no connection relationship between the mold cup 800 and the rotating skin pl...

Embodiment 2

[0037] A compact stuffed food forming machine includes a frame 100 and a station turntable 200 located on the frame 100, a leather making device 300, a filling device 400, a pressing device 500 and an outlet are respectively arranged around the station turntable 200. Material device 600, the leather making device 300 is a skin making station, the stuffing device 400 is a filling station, the pressing device 500 is a pressing station, and the discharging device 600 is a discharging station; A split forming mold is also arranged on the frame 100 , and the split forming mold includes a rotating skin plate 700 and a mold cup 800 which are independent of each other. The horizontal position of the rotary skin grafting plate 700 is higher than that of the station turntable 200 , and the rotary leather grafting plate 700 is located between the leather making device 300 and the station turntable 200 . There is no connection relationship between the mold cup 800 and the rotating skin pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com