Large-span multi-fulcrum single-beam crane

A multi-pivot, crane technology, applied in the directions of support structures, load hanging elements, rail systems, etc., can solve problems such as restricting factory construction, and achieve the effect of stable operation and large lateral span.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

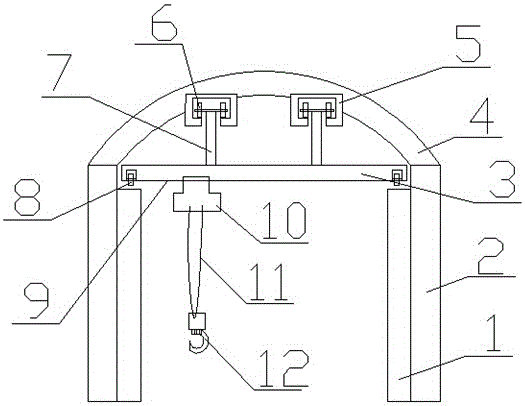

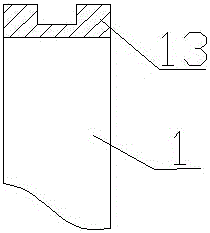

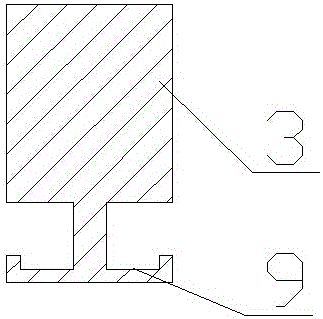

[0012] Such as figure 1 As shown, the present invention discloses a large-span multi-support single-girder crane, comprising: a main column 1, an auxiliary column 2, a main beam 3, an auxiliary beam 4, an auxiliary beam track groove 5, a guide wheel 6, and a guide wheel connecting rod 7 , load-bearing wheel 8, main beam track groove 9, hoisting motor 10, steel wire rope 11, suspension hook 12, load-bearing wheel track groove 13, described main column 1 is a cuboid structure welded by steel, and described main column The upper part of 1 is provided with a load-bearing wheel track 13 on which the load-bearing wheels 8 run. The auxiliary column 2 is welded by steel and is located outside the main column 1. The main beam 3 is a rectangular parallelepiped structure welded by steel. The auxiliary beam 4 is an arc-shaped structure welded by steel, and the lower end of the auxiliary beam 4 is welded on the auxiliary columns 2 on both sides. The guide wheel 6 is installed on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com