Protecting sleeve for open-installed pipeline

A technology for protective sleeves and pipelines, applied in pipeline protection, pipes/pipe joints/fittings, pipelines to prevent damage/wear, etc. It can solve problems such as poor durability, cumbersome installation, hanging and dragging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

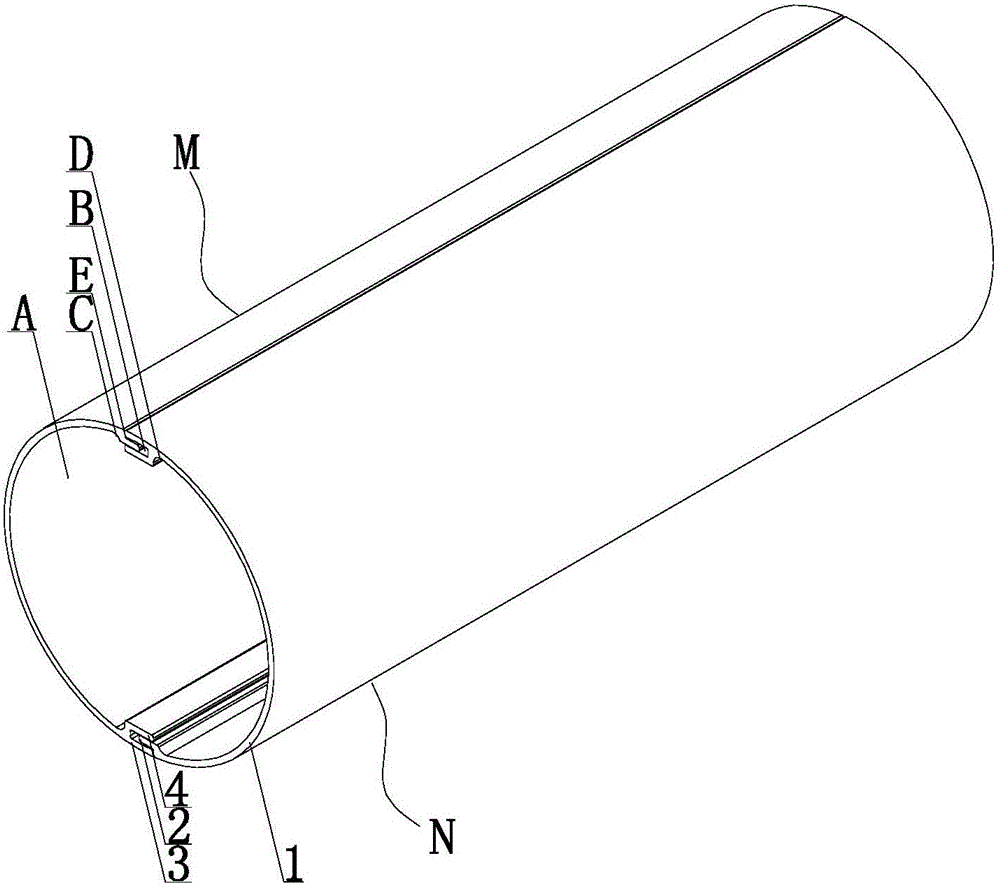

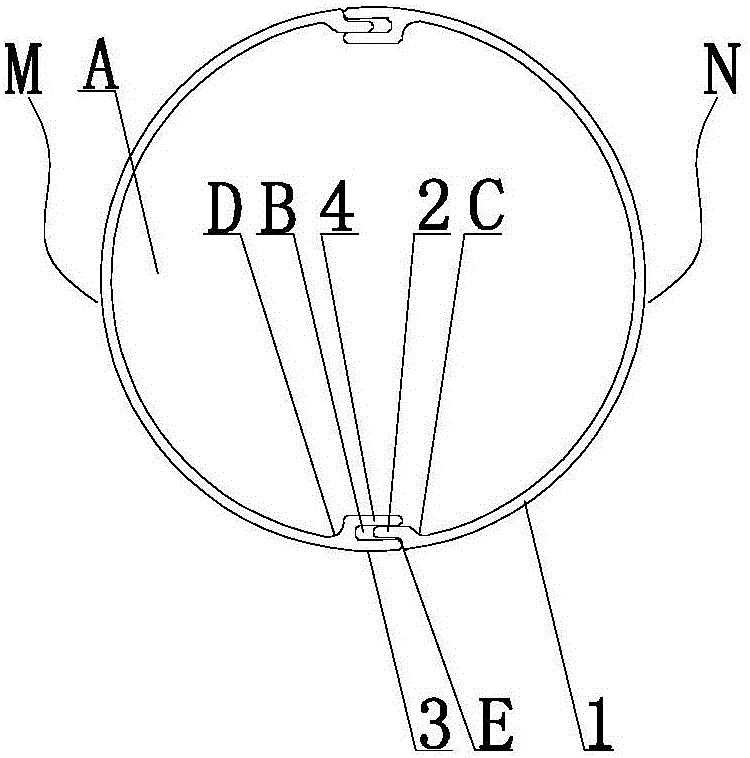

[0020] In this embodiment, the surface-mounted pipeline protection sleeve is combined with figure 1 and figure 2 , the protective cover is composed of component 1 M and component 2 N, component 1 M and component 2 N are used together, both include a body 1, a fastener 2, a bottom plate 3 and a top plate 4, the fastener 2 is located at one end of the body 1, The bottom plate 3 and the top plate 4 are located at the other end of the body 1; the fasteners of component 1 M are fitted between the bottom plate and the top plate of component 2 N, and the fasteners of component 2 N are fitted between the bottom plate and the top plate of component 1 M Component 1 M and 2 N are assembled together; Component 1 M and Component 2 N are surrounded to form an accommodating cavity A, and the surface-mounted pipeline is located in the accommodating cavity A.

[0021] Specifically in this embodiment, the fastener 2 protrudes longitudinally from the body 1 to the inside and then extends in a ...

Embodiment 2

[0025] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that a transition section 6 is provided between the fastener 2 and the body 1, and the transition section 6 can be set as a circular arc structure or as a right-angled surface Or slope structure, the fastener 2 forms a transition zone C above the transition section 6; a transition section 2 7 is provided between the top plate 4 and the body 1, and the transition section 2 7 can be set as a circular arc structure or a right angle Surface or slope structure, the top plate 4 forms a transition zone 2D above the transition section 2 7 .

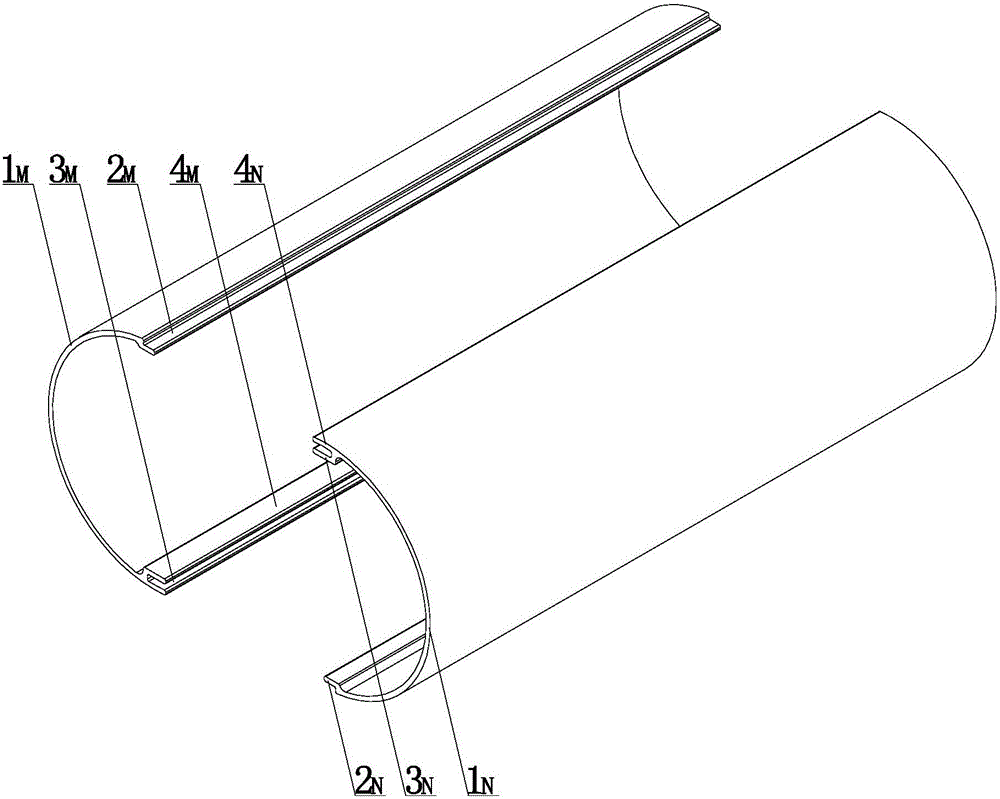

[0026] Applying this application to surface-mounted pipeline packaging, component 1M and component 2N can be directly mounted on the pipeline to be packaged, wherein component 1M consists of body 1 M , fastener one 2 M , bottom plate one 3 M and top plate one 4 M Composition, component two N consists of body two 1 N , fastener t...

Embodiment 3

[0029] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference lies in: combining image 3 and Figure 4, a transition section 6 is provided between the fastener 2 and the body 1, the transition section 6 can be set as a circular arc structure, or can be set as a rectangular surface or a slope structure, and the fastener 2 forms a transition area above the transition section 6 One C; a transition section 2 7 is provided between the top plate 4 and the body 1, the transition section 2 7 can be set as a circular arc structure, or can be set as a right-angled surface or an inclined plane structure, and the top plate 4 forms a transition area above the transition section 2 7 2D; a top block 5 is arranged below the fastener 2, and the top block 5 is extended by the body 1 along the direction parallel to the trajectory of the body 1, so that a buffer cavity filled with fixing glue is formed between the fastener 2, the bottom plate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com