Intelligent cloth inspecting machine with visual inspection function

A technology of visual inspection and cloth inspection machine, applied in the field of clothing equipment, can solve the problems of inability to fully tension the lotus leaf, unclear image acquisition, inconvenient assembly and transportation, etc., and achieves good lighting effect, convenient assembly and transportation, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

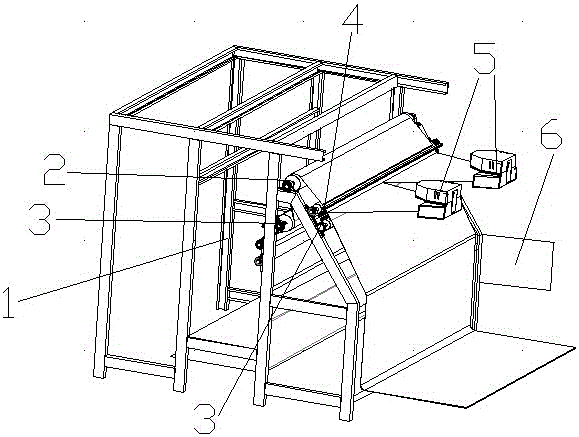

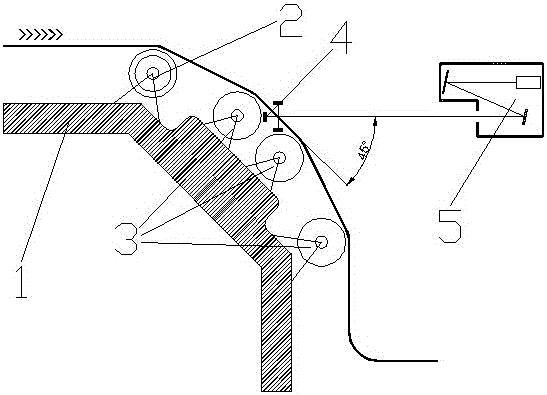

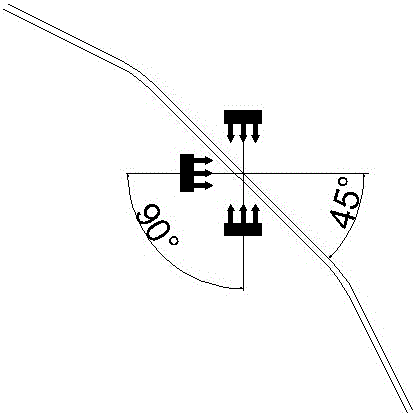

[0015] see figure 1 and figure 2 , an intelligent cloth inspection machine with visual detection, including a frame 1, tensioning and bending rollers 2, several feeding rollers 3, red, white and blue three-color light source groups 4, several cloth image acquisition units 5 and a touch screen 6. The tensioning bending roller 2 and the feeding roller 3 are arranged on the frame 1 along the cloth traveling direction from top to bottom and are spaced from each other by a certain distance, and the cloth is completely tensioned by the tensioning bending roller, In this way, the cloth will not have ruffles after entering, and the cloth image acquisition unit will be more clear when it is collected, which is convenient for subsequent analysis and processing. The red, white and blue three-color light source group 4 (such as image 3 shown) are set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com