Sealing ring

一种密封环、密封部的技术,应用在密封、发动机的密封、活塞环等方向,能够解决密封效果减弱等问题,达到降低维修费用、可靠密封效果、可靠密封的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

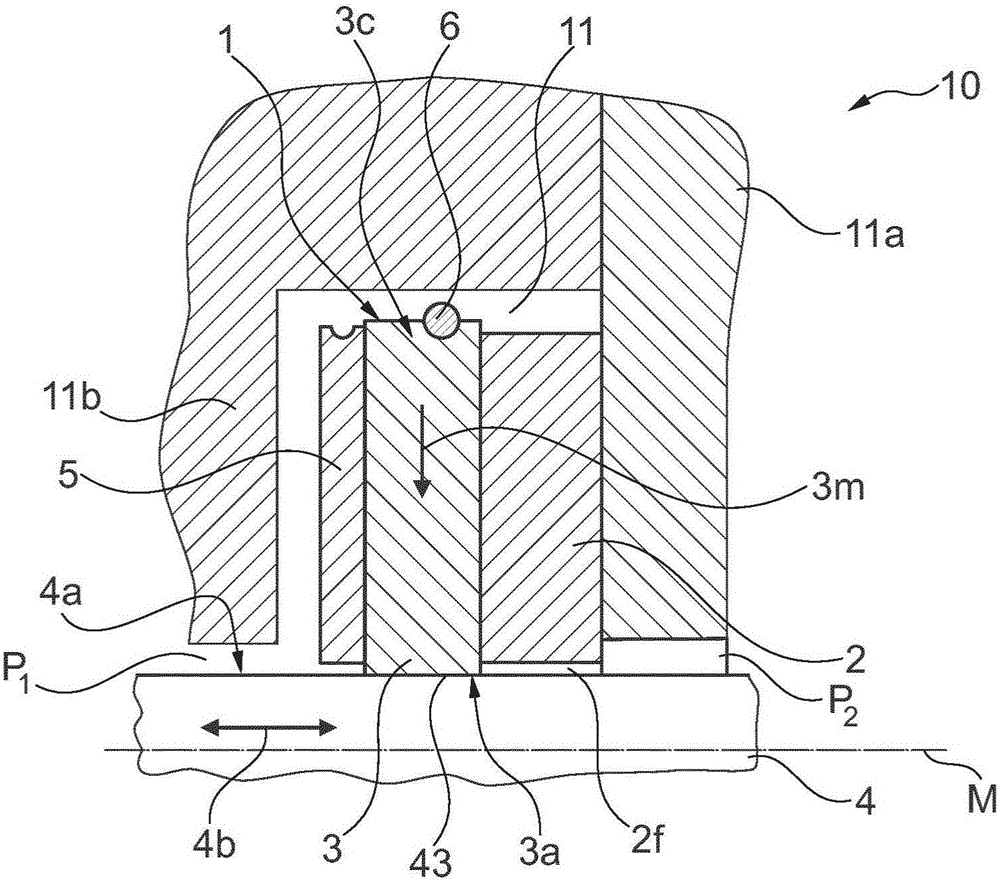

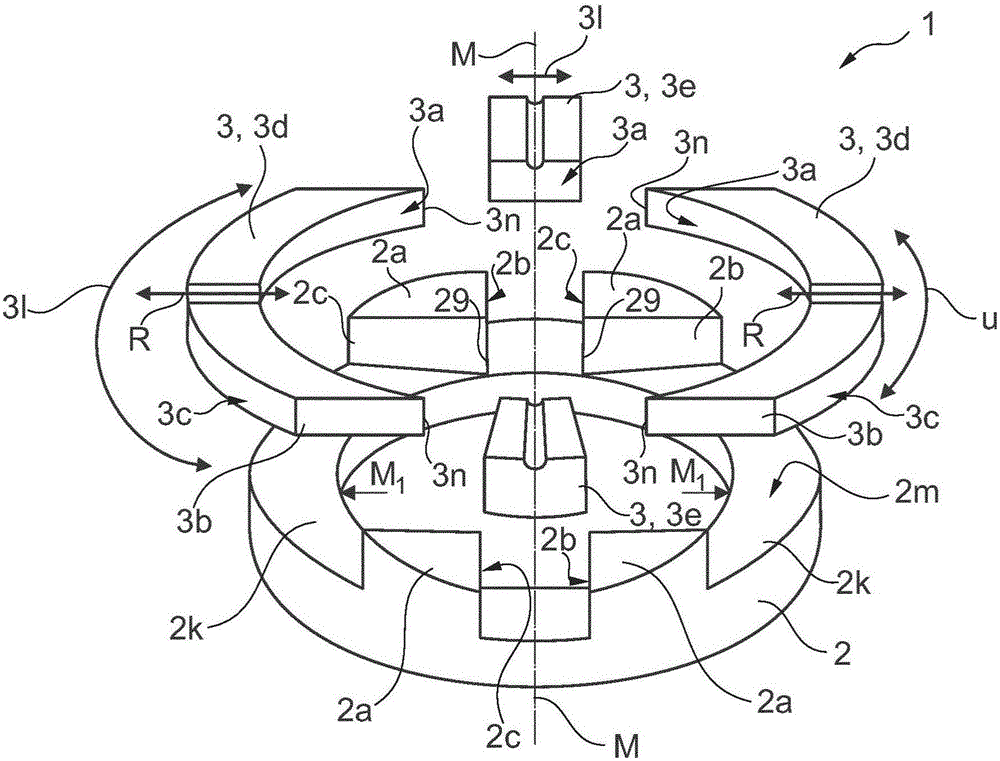

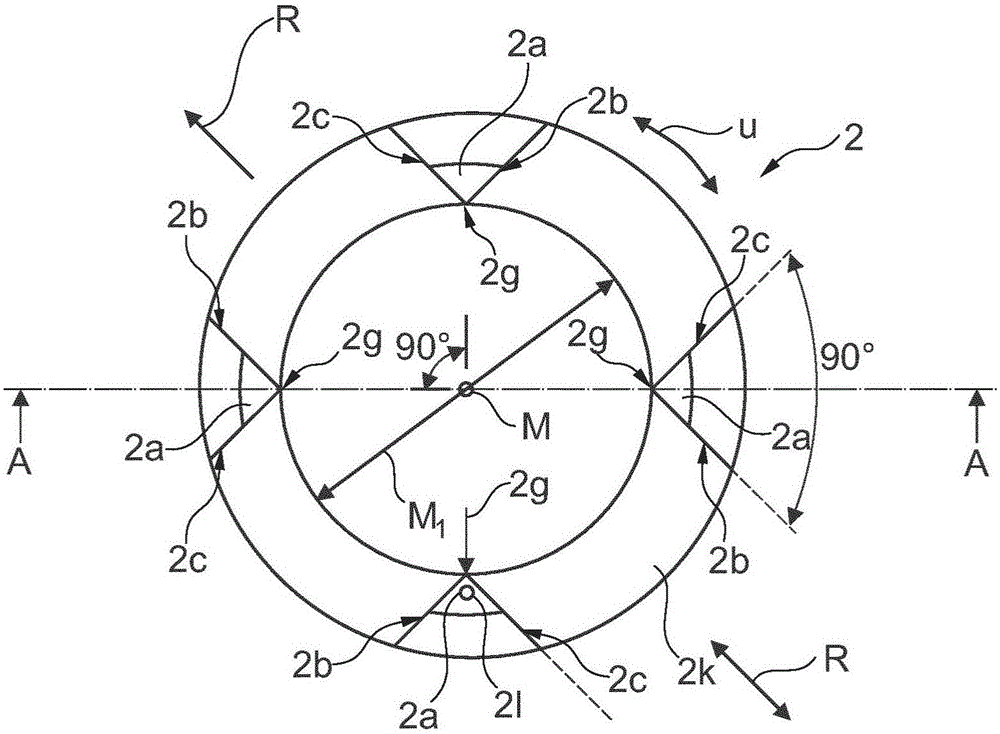

[0031] figure 1 A longitudinal sectional view of a sealing device 10 is shown for sealing a reciprocating piston rod 4 of a piston compressor in an axial direction 4a. The sealing device 10 preferably comprises a plurality of sealing chambers 11 arranged successively along the axis 4a, each having a first side wall 11a and a second side wall 11b, and a sealing ring 1 is arranged in each sealing chamber 11. The air pressure in the sealing chamber 11 drops from a higher pressure P1 to a lower pressure P2 through the sealing ring 1 . This pressure drop is achieved in particular via a sealing gap 43 formed between the end face 3 a of the sealing section 3 and the surface 4 a of the piston rod 4 . as in figure 2 As shown in the embodiment, the sealing ring 1 of the present invention includes a fixed ring 2 extending to 360°, the fixed ring has a circular inner diameter M1 and a central axis M, and the sealing ring includes a plurality of radially movable supports along the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com