A shot blasting device with an adjustable hanger

A shot blasting device and an adjustable technology, which is applied in the direction of used abrasive processing devices, abrasives, metal processing equipment, etc., can solve the problems of inability to adjust, narrow applicable range, etc., and achieve a wide range of spray coverage and increase the application Good range and processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

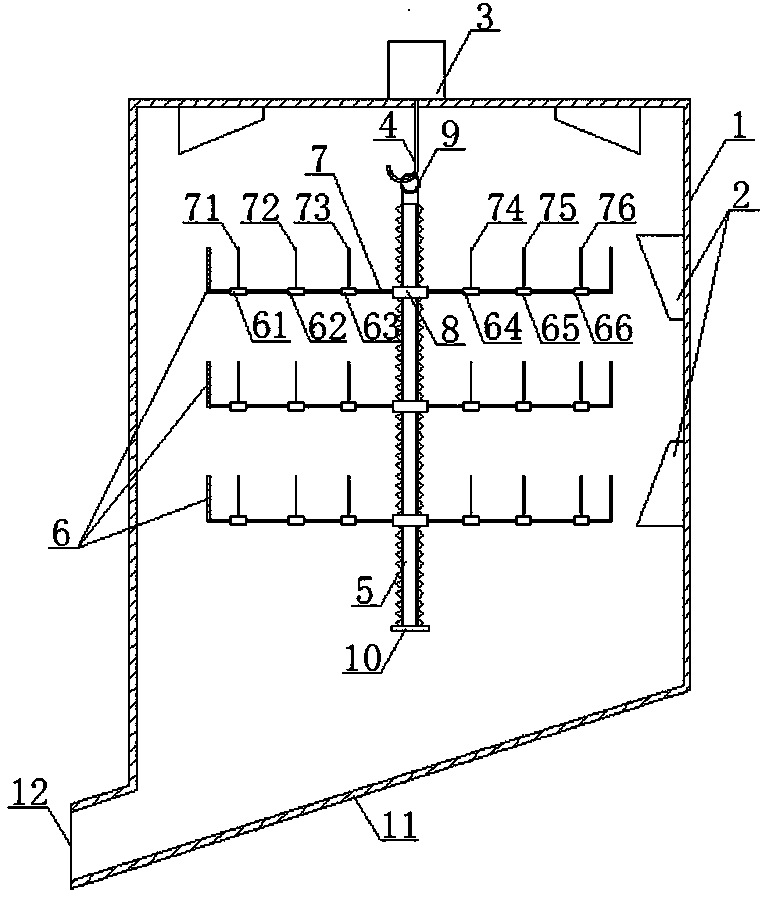

[0018] see figure 1 , is a structural schematic diagram of the shot blasting device with an adjustable hanger of the present invention.

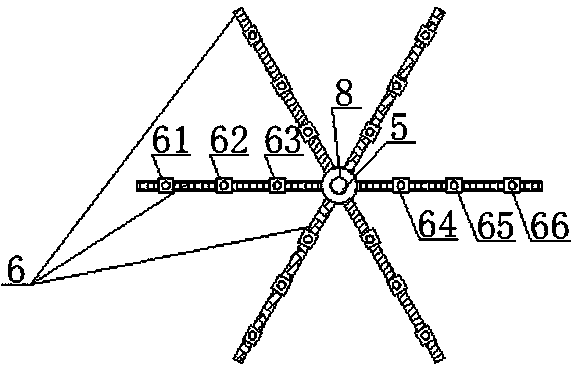

[0019] like figure 1 As shown, a shot blasting device with an adjustable hanger of the present invention includes a body 1, a sandblasting port 2, a drive motor 3, a rotating rod 4, a boom 5, and a hanger 6, wherein the sandblasting port 2 is set On the side and top plate in the body 1; where the rotating rod 4 is connected with the drive shaft of the drive motor 3; where the end of the rotating rod 4 is provided with a curved hook; where the suspender 5 surface is provided with threads, and the upper end is provided with Ring 9; Wherein hanger 6 comprises support bar 7, swivel 8, first slider 61, second slider 62, third slider 63, fourth slider 64, fifth slider 65, sixth slider 66. The first hanging rod 71, the second hanging rod 72, the third hanging rod 73, the fourth hanging rod 74, the fifth hanging rod 75, and the sixth hanging rod 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com