Intermediate packaging machine compression device for disposable absorbent articles

A compression device and absorbent technology, applied in packaging, presses, manufacturing tools, etc., can solve problems such as inability to transport at high speed, reduce equipment stability, and product extrusion and scatter, and achieve enhanced compression torque and compression stability. The effect of pushing smoothness and fast production and processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but the claims of the present invention are not limited in any way.

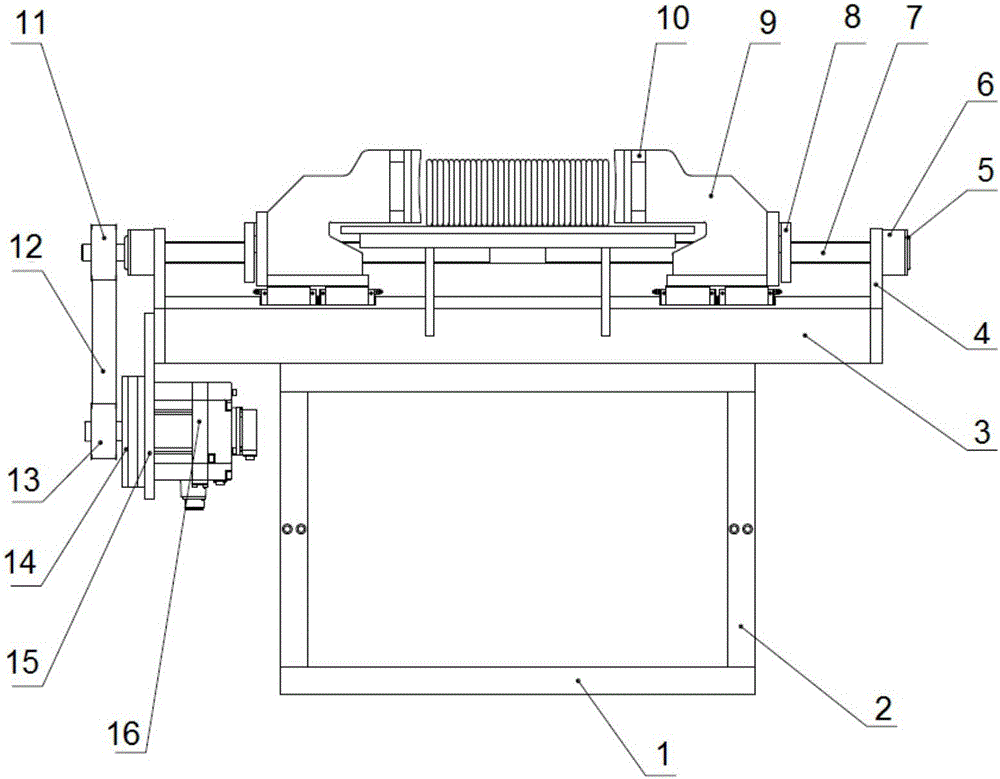

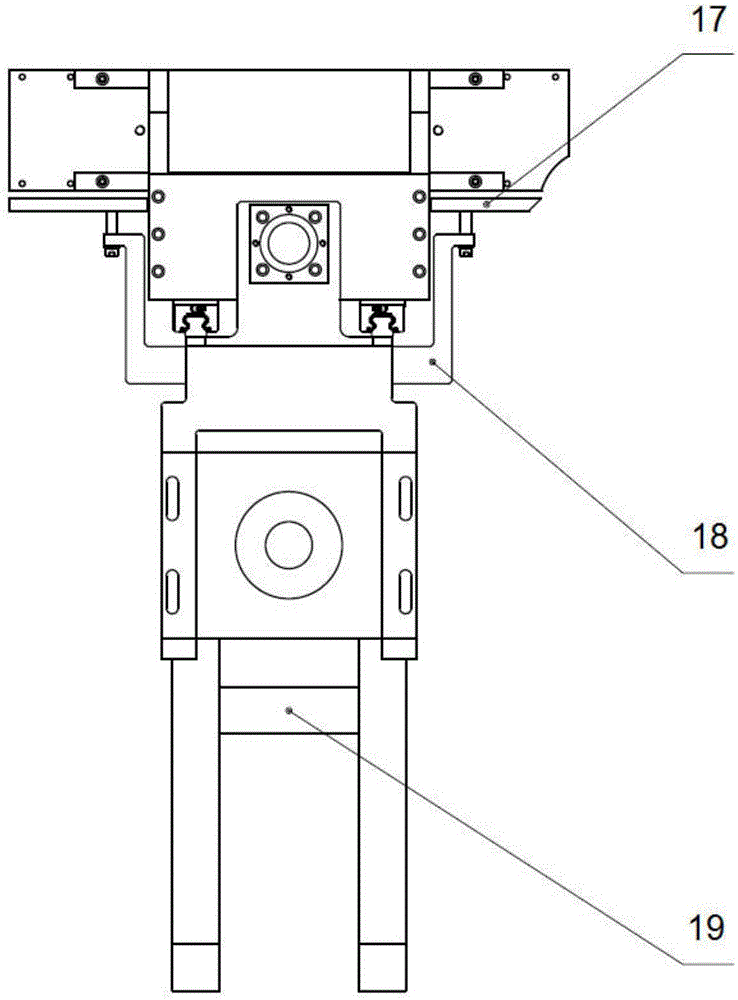

[0030] Such as Figure 1~5 As shown, the compression device of the tundish machine for disposable absorbent articles in this embodiment includes a compression bracket, a compression plate mechanism and a compression translation mechanism installed on the bracket, wherein:

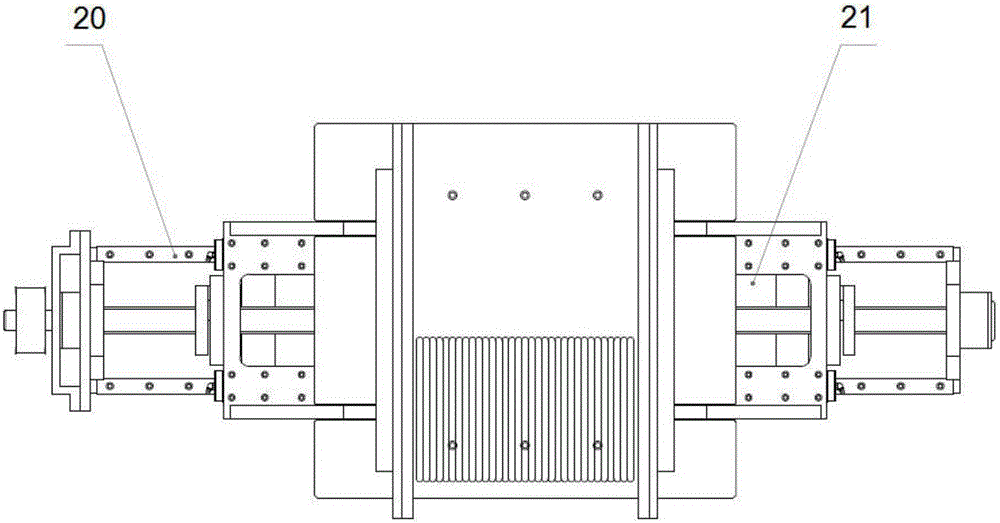

[0031] The compression support includes a frame formed by beams 1 and columns 2, a panel bracket 3 arranged above the frame, and a panel 17 fixedly connected to the top of the bracket 3 for carrying products. Fixed connection; double sliding rails 20 are provided on the panel bracket 3; short columns 19 for fixed connection are provided between the columns 2.

[0032] The compression plate mechanism includes a left compression mechanism and a right compression plate mechanism arranged symmetrically on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com