Device for detecting assembly of sealing rings

An assembly detection and sealing ring technology, applied in geophysical measurements, instruments, etc., can solve problems affecting product quality, improve assembly quality and assembly efficiency, prevent missing assembly, and avoid product rework.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

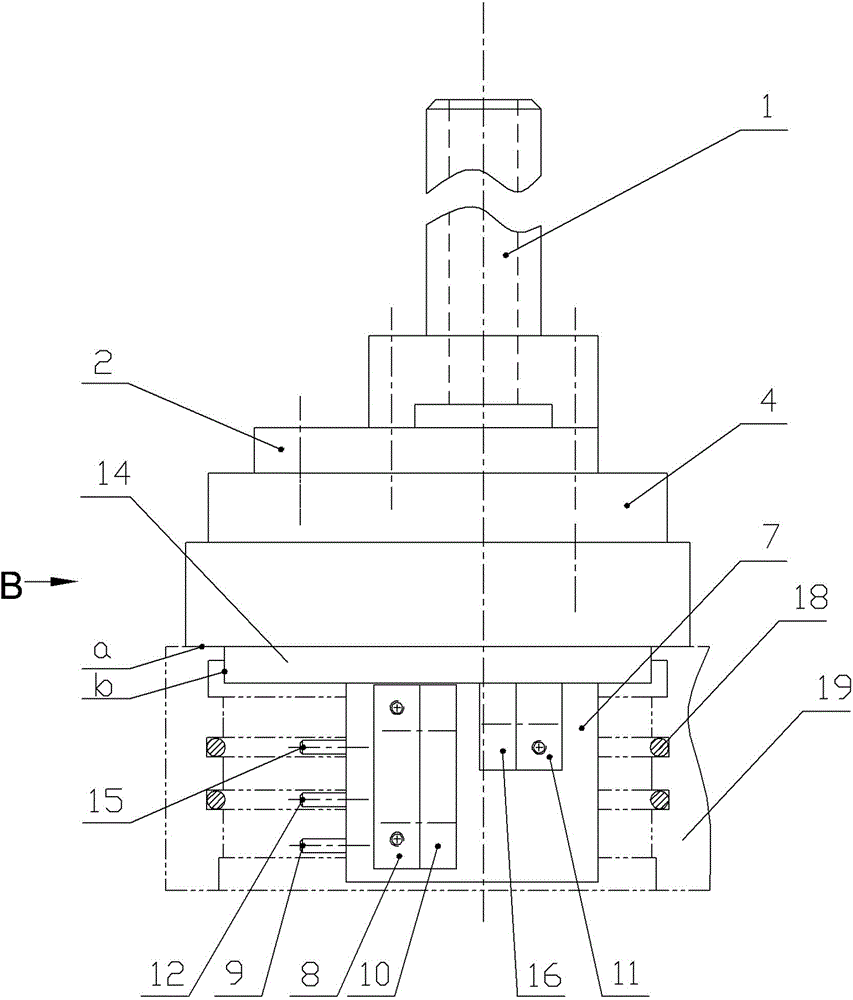

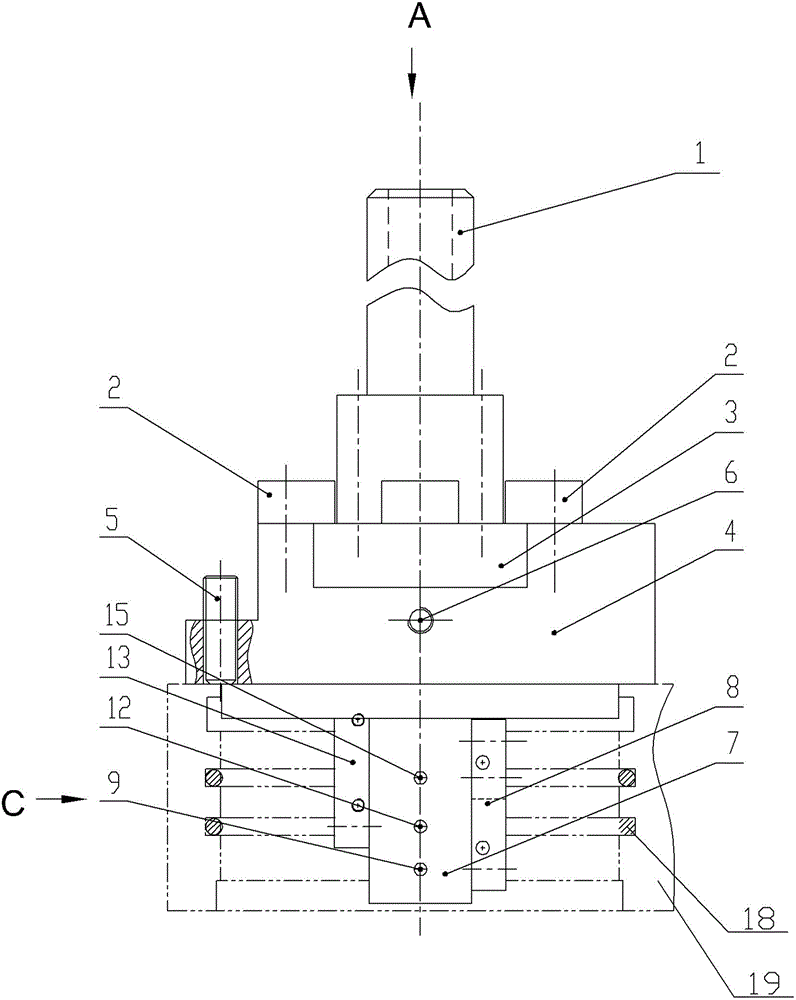

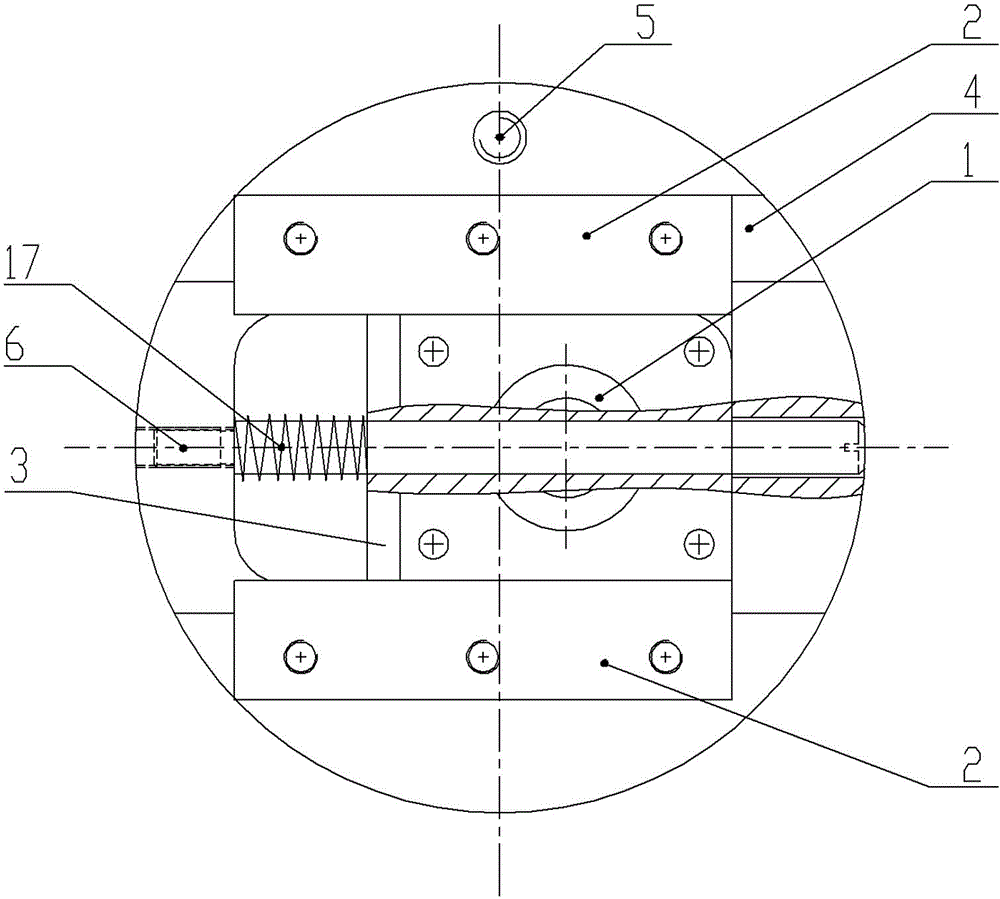

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the sealing ring assembly detection device includes a positioning seat 4 for mating with the piston cylinder 19 to realize the positioning of the detection device. A slider 3 is slid in the middle of the positioning seat 4 along its radial direction. The front part is fixedly installed with a detection arm 7 that protrudes from the positioning seat 4 and moves synchronously with the slider 3. On the detection arm 7, two main probes for detecting the sealing ring extending radially along the positioning seat 4 are installed. The main probes are the first probe 12 and the second probe 15, the first probe 12 and the second probe 15 are arranged in sequence along the axial direction of the detection arm 7, the number of the main probes and its axial direction of the detection arm The position and spacing correspond to the number of sealing rings 18 to be tested in the piston cylinder and their positions and sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com