Anti-neglected-assembly device

A technology for leak-proof assembly and assembly stations, which is applied in the direction of assembly machines, metal processing machinery parts, measuring/indicating equipment, etc., can solve problems that affect work efficiency, are difficult to find, and miss-installed parts, etc. Easy-to-implement, simple-structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

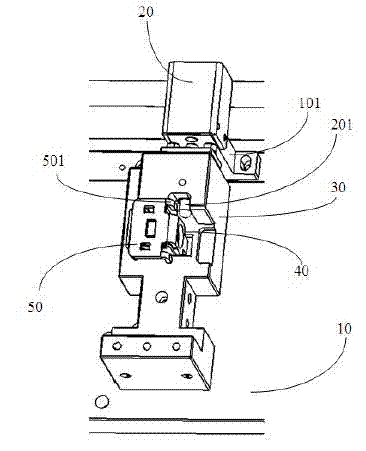

[0016] ginseng figure 1 As shown, in one embodiment of the present invention, the leak-proof device includes a substrate 10; a displacement sensor 20 mounted on a fixed frame 101 on the substrate 10; a detection member 201, one end of which is connected to the displacement sensor 20 connection, and the other end stretches into assembly station 30 li.

[0017] When the part 40 to be assembled is correctly put into the assembly station 30, a hooked part 401 on the part 40 to be assembled will conflict with the detection piece 201, causing the detection piece 201 to be displaced, driving the spring (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com