Aluminum cap pressing jig for grass trimmer head

A technology of pressing fixtures and mowers, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of high manual work intensity, low labor efficiency, and increased enterprise cost expenditures, so as to reduce enterprise costs The effect of expenditure, high degree of automation, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

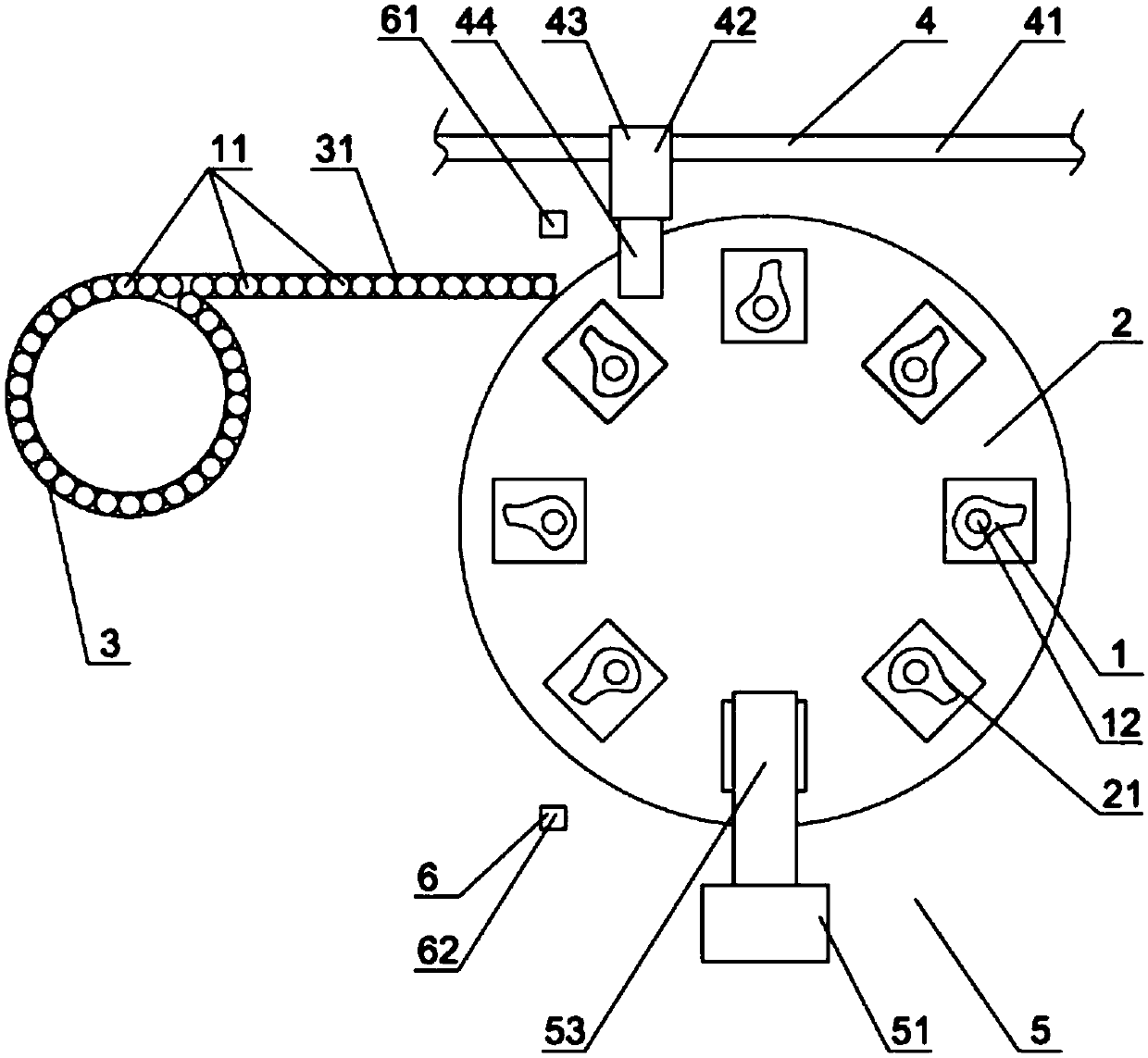

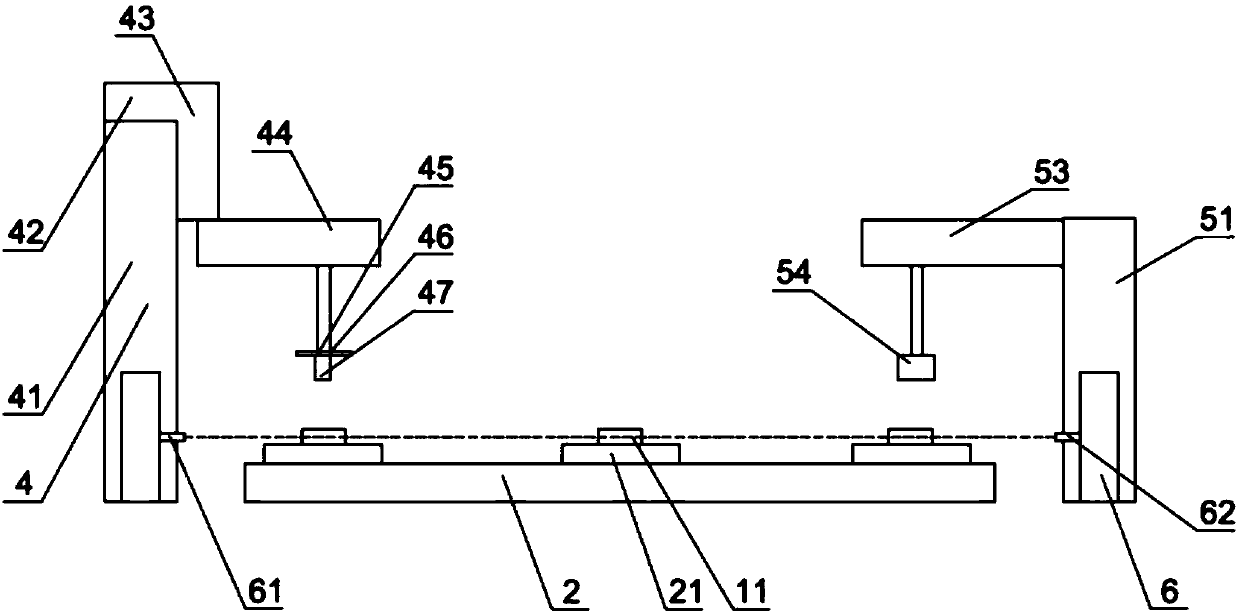

[0019] Such as Figure 1 to Figure 2 As shown, the present invention discloses a pressing fixture for the aluminum cap of the trimmer head, which includes a trimmer workpiece 1 and an aluminum cap 11, the trimmer workpiece 1 is provided with a groove 12, and the aluminum cap 11 It can be plugged into the groove 12, and the two are tightly fitted.

[0020] The pressing fixture for the aluminum cap of the mowing machine head in the present invention at least includes a turntable 2 that is arranged on the frame and can rotate by itself. The turntable 2 can be driven by a driving motor arranged belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com