A rotary transport mechanism

A technology of handling mechanism and rotating shaft, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as reduced reliability and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

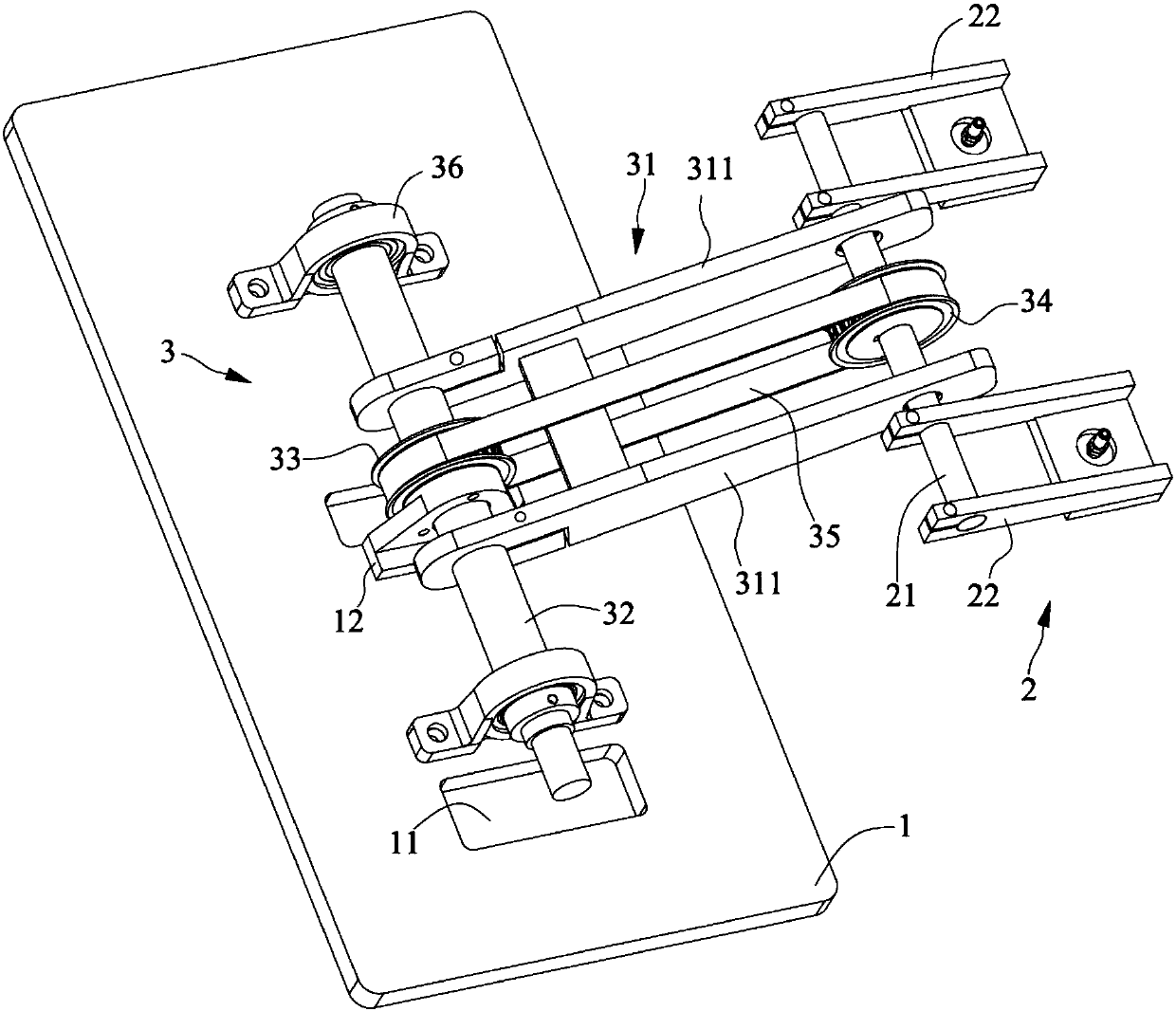

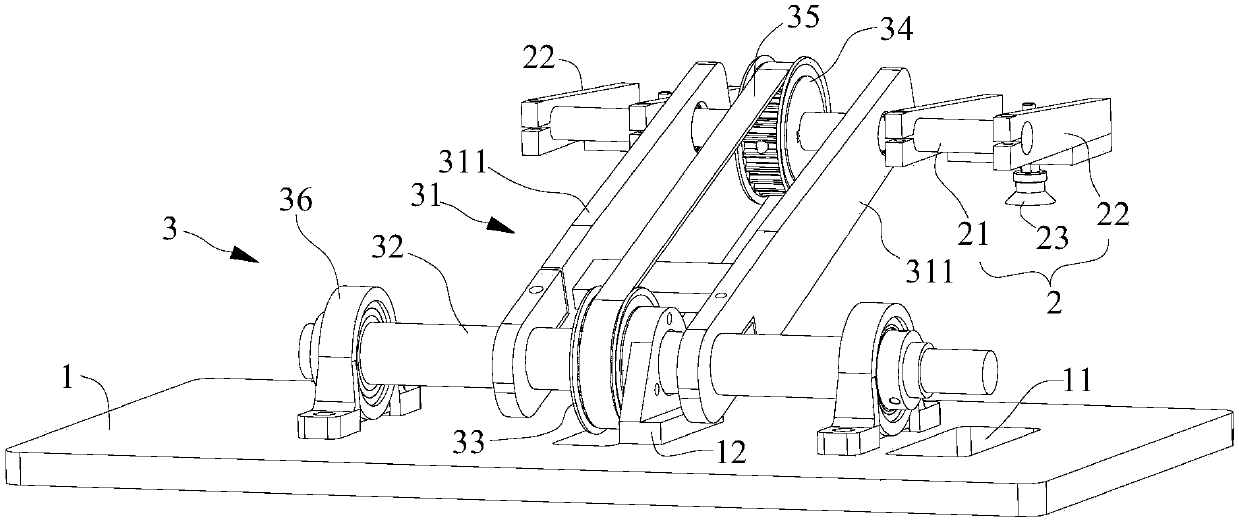

[0023] Please refer to figure 1 and figure 2 , this embodiment provides a rotary transport mechanism, including a base plate 1, a transport assembly 2, a rotary assembly 3 and a rotary shaft driver, and the rotary assembly 3 includes a rotary arm 31, a rotary shaft 32, a first synchronous wheel 33 and a second synchronous Wheel 34, the two ends of rotating shaft 32 are connected to base plate 1, and the bottom end of rotating arm 31 is provided with rotating hole, and rotating shaft 32 passes through rotating hole and first synchronous wheel 33, and first synchronous wheel 33 is relatively fixed with base plate 1, The rotating arm 31 is rotatable with the bottom plate 1, and the transport assembly 2 includes a connecting shaft 21 and a transporting arm 22 for carrying articles. The transporting arm 22 and the second synchronous wheel 34 are fixed on the connecting shaft 21, and the connecting shaft 21 is rotatable. Passing through the top of the rotating arm 31 , the first s...

Embodiment 2

[0027] The difference from Embodiment 1 is that the end of the rotating shaft 32 in this embodiment is fixed on the bottom plate 1, the rotating arm 31 and the rotating shaft 32 can rotate, and the rotating shaft driving part drives the rotating arm 31 to rotate, and no longer drives the rotating shaft. 32 turns. The bottom of the rotating shaft driving part is fixed on the bottom plate 1, and the rotating shaft driving part may include a driving gear, and a sector gear is arranged on the outside of the bottom end of the rotating arm 31, and the sector gear meshes with the driving gear. The rotating shaft driving member can also be a sprocket or a belt pulley, etc., and a corresponding sprocket or belt pulley is arranged outside the bottom end of the rotating arm 31 to directly drive the rotating arm 31 to rotate through a chain or a belt.

Embodiment 3

[0029]The difference from the above-mentioned embodiment is that in this embodiment, one side of the first synchronous wheel is relatively fixed to the bottom plate through a locking device, and the other side is connected to the output shaft of the adjustment motor, and the adjustment motor is fixed to the bottom plate. The locking device includes a friction clutch and The locking seat, the locking seat is fixed to the bottom plate, and the fixing and separation between the first synchronous wheel and the locking seat are realized by adjusting the separation and combination of the clutch plates in the friction clutch. When transporting, by turning the rotating arm, the transporting arm is moved to the attachment of the product to be transported. At this time, the separation of the clutch plate can be adjusted so that the first synchronous wheel and the locking seat are no longer fixed. The rotation of the motor drives the first synchronous wheel to rotate, and then drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com