Automatic coiling machine for inner tyre

An automatic coiling and inner tube technology, which is applied in the field of coiling machines, can solve problems such as difficulty in meeting the needs of inner tube coiling, and achieve the effects of improving coiling efficiency, reducing labor costs, and improving the pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

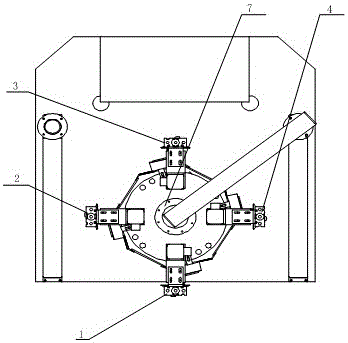

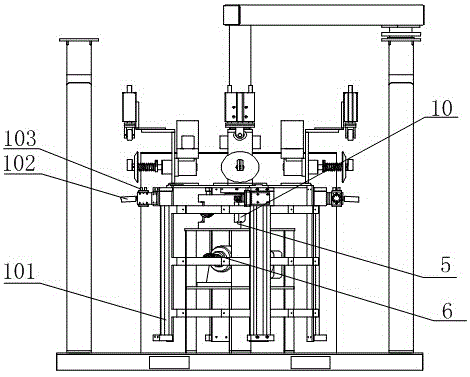

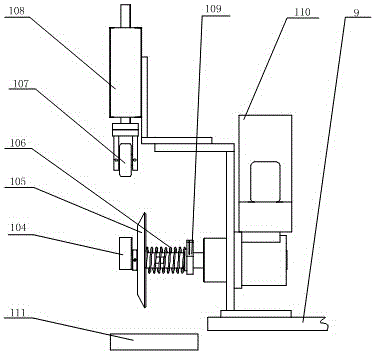

[0022] Such as Figure 1 ~ Figure 4 As shown, the inner tube automatic coiling machine disclosed by the present invention includes a bracket, a first motor reducer installed on the bracket, a turntable located above the first motor reducer and driven by the first motor reducer, and distribution The tire loading station, coiling and folding station, plastic inspection station and take-out station on the turntable, wherein, the tire loading station is provided with a folding seat driven by the second motor reducer, and is located at The pressure wheel driven by the third cylinder above the folding seat, and the tire-folding bar located below the folding seat, and a side plate and a spring are also arranged between the folding seat and the second motor reducer; Rollers driven by the first cylinder and the second cylinder are also arranged on the coiling and folding station.

[0023] Further, an intermittent mechanism is also provided between the first motor reducer and the turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com