Jet device capable of improving cavitation performance of jet type centrifugal pump

A technology for centrifugal pumps and jets, applied in the field of jets, can solve the problems of induced vibration and noise, drop of head of jet centrifugal pumps, and restricted flow operating range, etc., to achieve the effect of increasing the operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

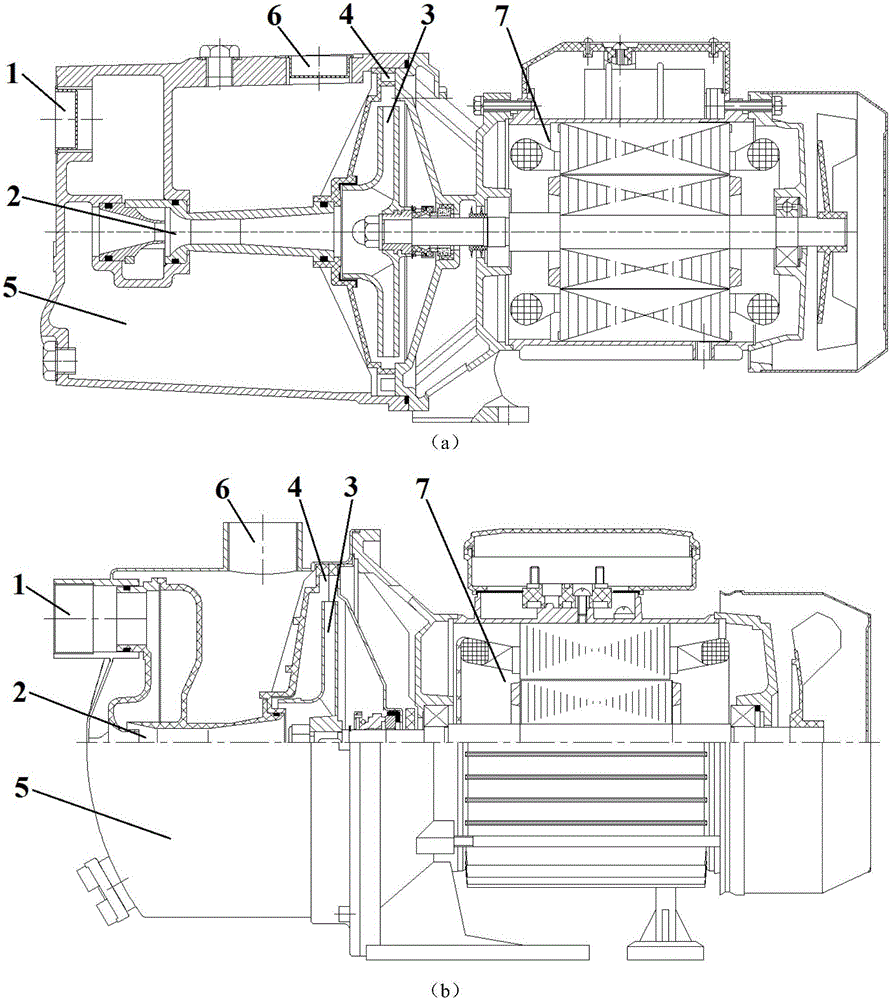

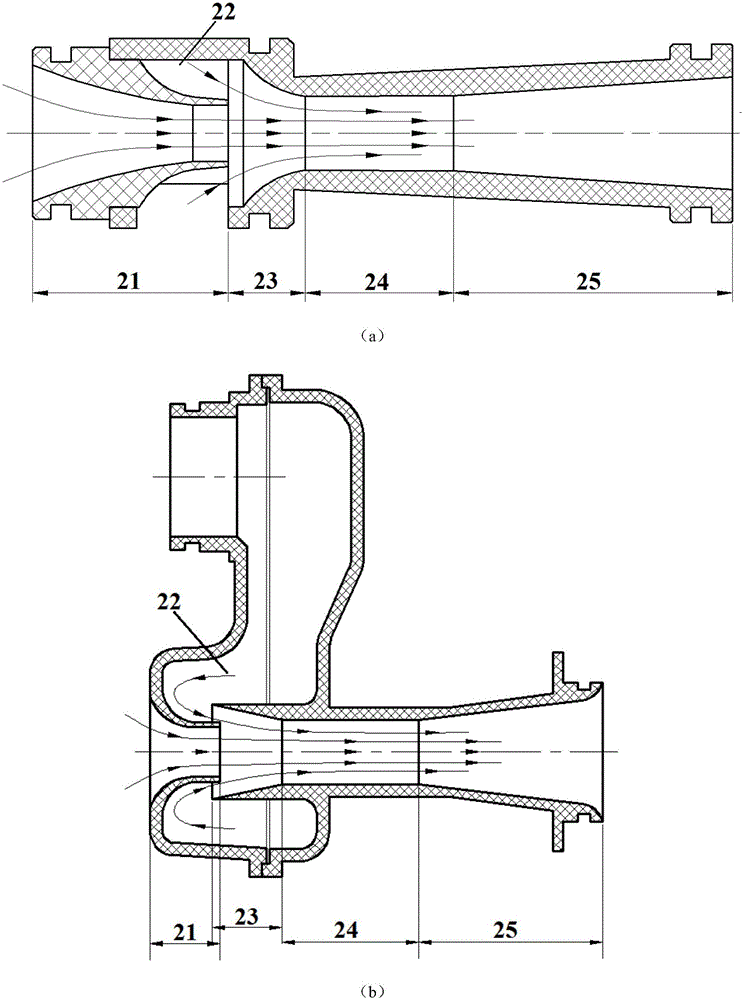

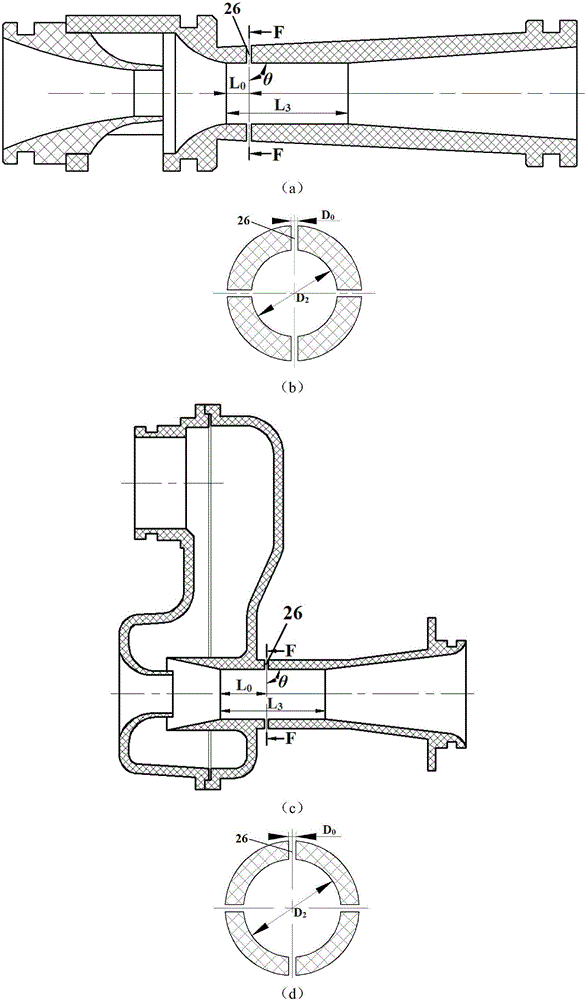

[0031] image 3 Shown is a schematic structural view of an ejector 2 that can improve the cavitation performance of a jet-type centrifugal pump according to the present invention. The ejector 2 of the jet-type centrifugal pump includes a nozzle 21, a drainage section 22, a mixing section 23, a throat Tube 24, diffuser section 25 and booster hole 26.

[0032] Such as figure 2 As shown, when the jet centrifugal pump operates under the condition of large flow rate, cavitation will occur inside the throat of the jet, which will cause the pump head to drop sharply and induce vibration and noise at the same time. Such as Figure 4 As shown, when the booster hole 26 is designed at the throat 24 of the ejector 2, the booster hole 26 introduces the high-pressure liquid in the pump chamber 5 into the low-pressure area of the throat 24, increases the pressure in the low-pressure area of the throat 24, and improves the jet flow. Anti-cavitation performance of centrifugal pump ejec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap