Electric heating unit and thermal-storage electric boiler with same

An electric heating and electric heating tube technology, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as troublesomeness and short average service life, and achieve increased connection structure, convenient operation, and guaranteed use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

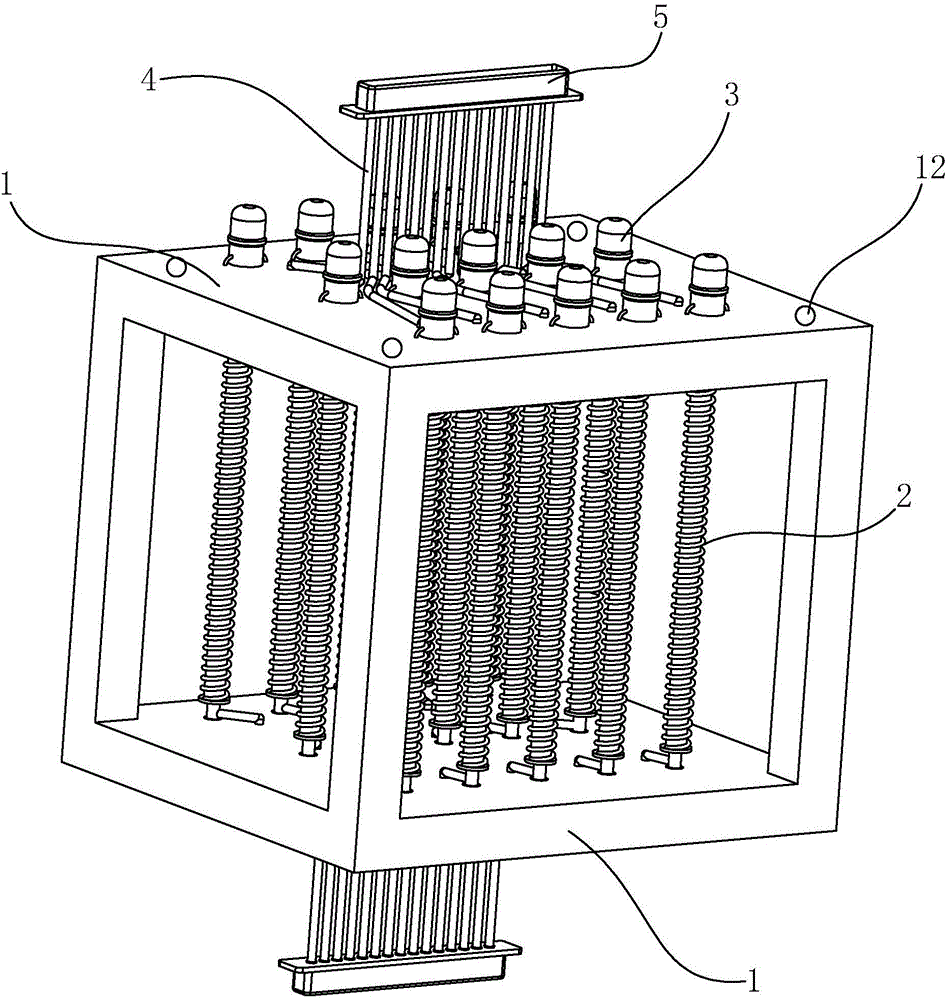

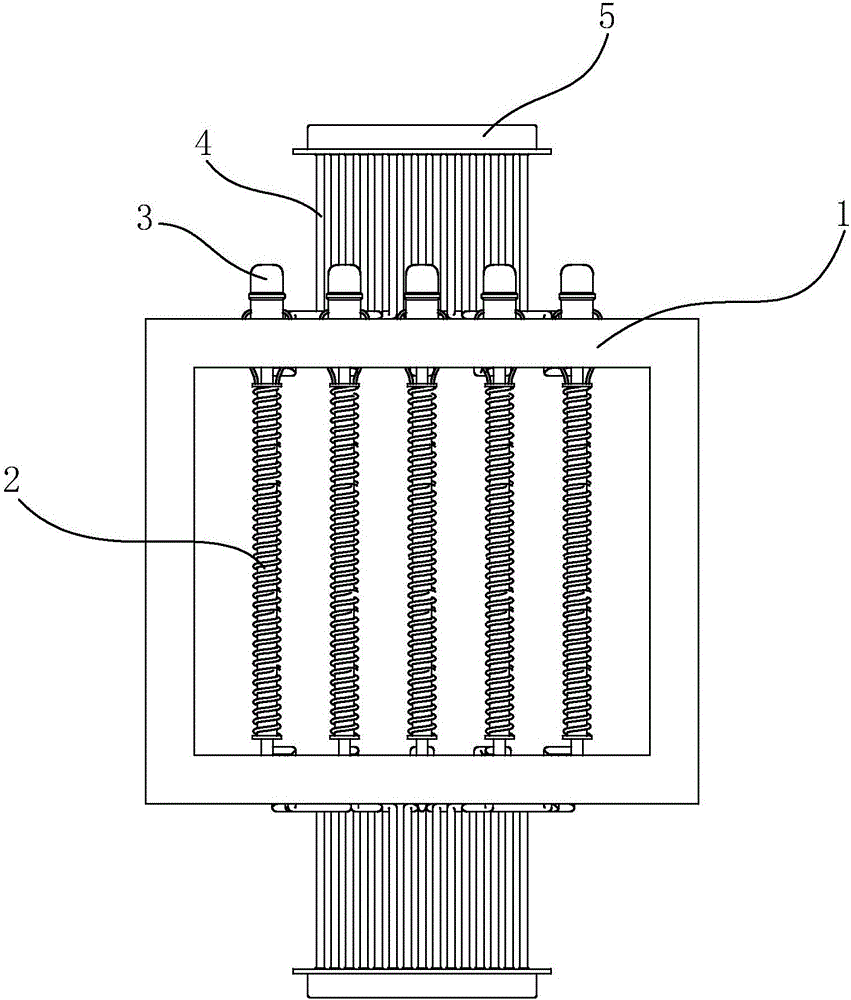

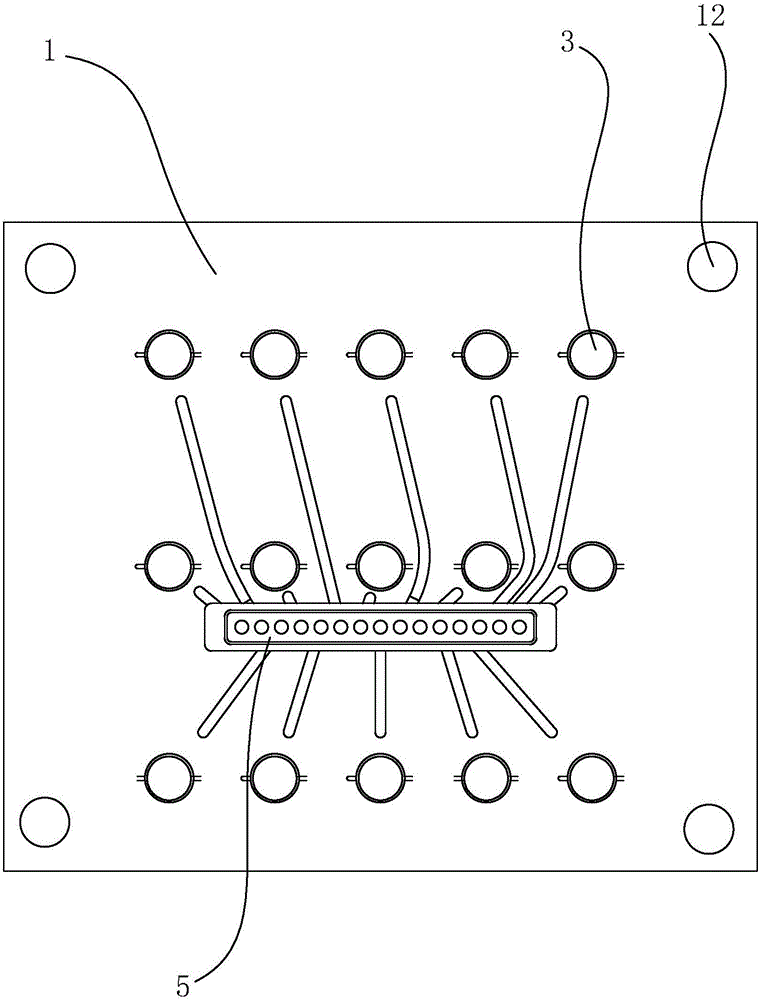

[0044] Embodiment 1: an electric heating unit, such as figure 1 and figure 2 As shown, there are two upper and lower oppositely arranged electric heating tube fixing plates 1 made, and as Figure 4 and Figure 5 As shown, a number of installation holes 7 are opened on the electric heating tube fixing plate 1. The installation holes 7 on the upper and lower two electric heating tube fixing plates 1 are oppositely arranged and their centers are located on the same axis. Between the upper and lower corresponding installation holes 7 The electric heating tube 2 is installed, and the two ends of the electric heating tube 2 are snapped into the installation holes 7 respectively, and a limit assembly is installed in the installation holes 7 for fixing the electric heating tube 2 .

[0045] like Figure 5 As shown, the limit assembly includes a snap ring 8, a hole in the middle of the snap ring 8 is adapted to the electric heating tube 2, and an annular stop protrusion 6 is arrang...

Embodiment 2

[0047] Embodiment two: an electric heating unit, such as Image 6 and Figure 7 As shown, the difference from Example 1 is that the electric heating tube 2 and the snap ring 8 are connected in a different way. An internal thread is provided inside, and an external thread is provided at both ends of the electric heating tube 2, so that the connection mode between the electric heating tube 2 and the snap ring 8 is threaded connection, which can further increase the distance between the electric heating tube 2 and the snap ring 8. The connection is stable, and there will be no accidental detachment due to external vibrations. When installing or disassembling, first press one end of the electric heating tube 2 to the snap ring 8, then make the electric heating tube 2 appear in a vertical state, and then rotate the electric heating tube 2 The heating tube 2 makes the electric heating tube 2 tighten the inside of the snap ring 8 through threads, and then the other end is screwed ag...

Embodiment 3

[0048] Embodiment three: an electric heating unit, such as Figure 8 and Figure 9 As shown, the difference from Embodiment 1 is that the electric heating tube 2 is connected to the snap ring 8 in a different way. In this scheme, a jumping bean spring 10 structure is installed on the inner wall of the hole of the snap ring 8, and the two ends of the electric heating tube 2 are respectively There is a groove 11, so that when the electric heating tube 2 needs to be installed in the snap ring 8, one end of the electric heating tube 2 extends into the hole of the snap ring 8, and then when the electric heating tube 2 is turned, it is in a compressed state. The jumping bean spring 10 just turns into the groove 11 and stretches into the groove 11 to resist it, so that the electric heating tube 2 can be stably fixed, and at this time, under the action of the spring 9, the other end extends into the snap ring 8 In the hole, turn the electric heating tube 2 at this time, the snap ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com