Direct-current bus voltage control method based on PID algorithm

A technology of DC bus voltage and control method, which is applied in the direction of calculation, instrumentation, data processing, etc., which can solve the problems of lack of market competitiveness of products, power consumption of braking units, and small profit margins, so as to reduce electricity expenses and eliminate wear and tear , the effect of increasing the profit margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

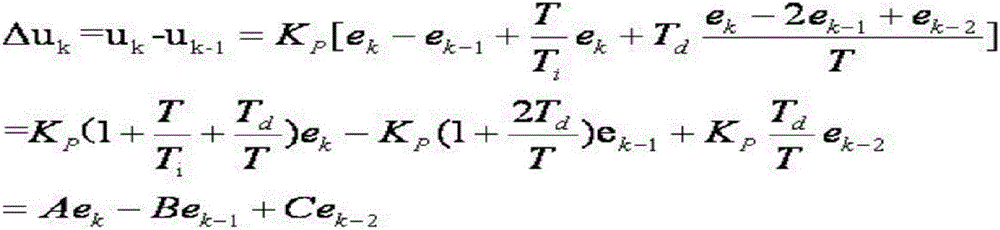

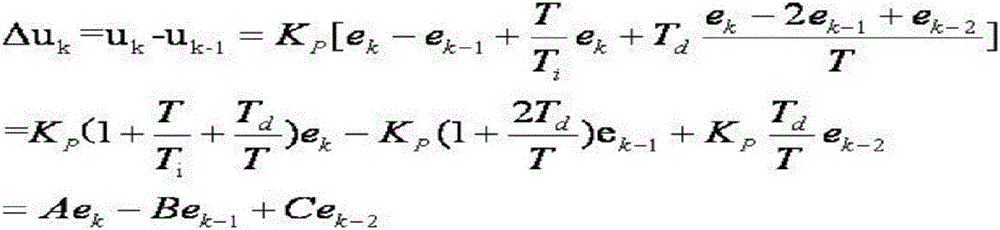

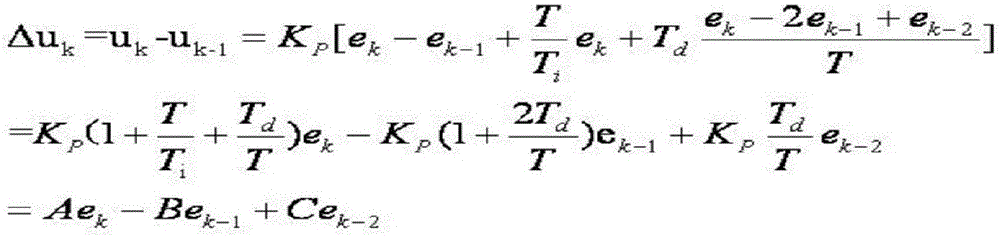

Method used

Image

Examples

Embodiment Construction

[0018] A PID algorithm-based DC bus voltage control method,

[0019] Take the following steps:

[0020] a. Set the given amount S(k) for PID regulation. The value of S(k) is set as the percentage of the three-phase input standard bus voltage Uref and the maximum bus voltage Umax allowed during system operation, that is, Uref / Umax (people The value of different maximum bus voltage Umax can be set according to different equipment, so that the adjustment method of the present invention has a wider adaptability);

[0021] b. Set the feedback amount F(k) for PID adjustment, and the value of F(k) is set as the percentage of the real-time bus voltage Udc to be detected and the maximum bus voltage Umax, that is, Udc / Umax (because there will be Larger voltage fluctuations, so the combination of real-time tracking bus voltage and PID adjustment algorithm can intelligently track voltage fluctuations caused by frequency changes, and compare the difference between the feedback amount obta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap