Novel electric cylinder structure

An electric cylinder, a new type of technology, applied in the directions of electric components, electrical components, electromechanical devices, etc., can solve the problems of reducing the overall size of the electric cylinder, and achieve the effects of low manufacturing cost, simple and compact structure, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

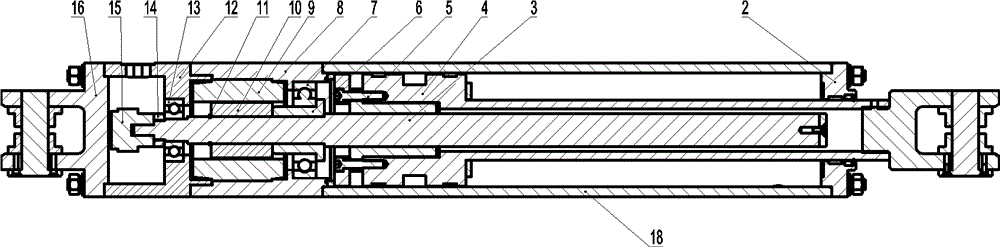

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

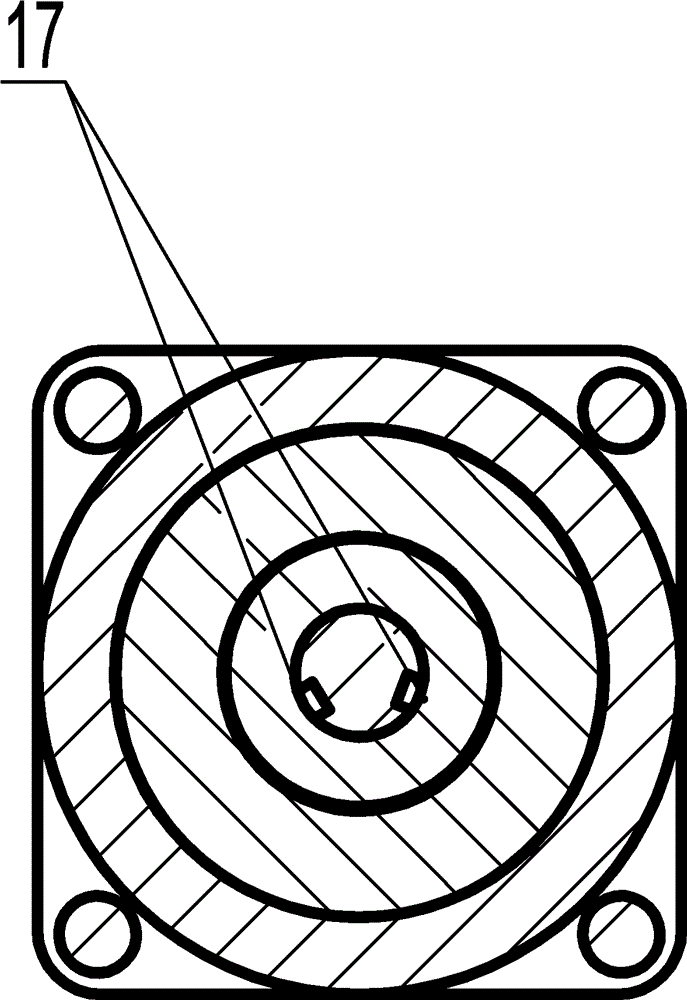

[0014] In the figure, the bearing sleeve (5) is installed together with the screw nut pair (3) by interference fit, and the rotor (10) and the screw nut pair (3) are connected through the A-shaped flat key (17). The sleeve (6) and the B-type shaft are axially positioned with a circlip (11), and the stator (9) is pressed into the bearing seat (8) by a press, and is fixed through the protruding stop of the encoder box (12). Compress to meet the axial positioning, the bearing (7) and the bearing (13) are installed on the screw nut pair (3), and the lock nut (14) is used for positioning and tensioning, and the rotor of the encoder (15) is installed on the screw On the end shaft of the nut pair (3), the encoder (15) stator is fixed on the encoder box (12) by screws. The above steps have realized the transformation of the traditional motor, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com