Centrifugal compaction ridge forming machine

A technology of building a ridge machine and a compacting roller, which is applied in the fields of farming equipment, agricultural machinery and equipment, and application, etc., can solve the problems of poor ridge top compaction effect, inability to achieve the pressure bearing capacity of the ridge body, and the influence of the size of the soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

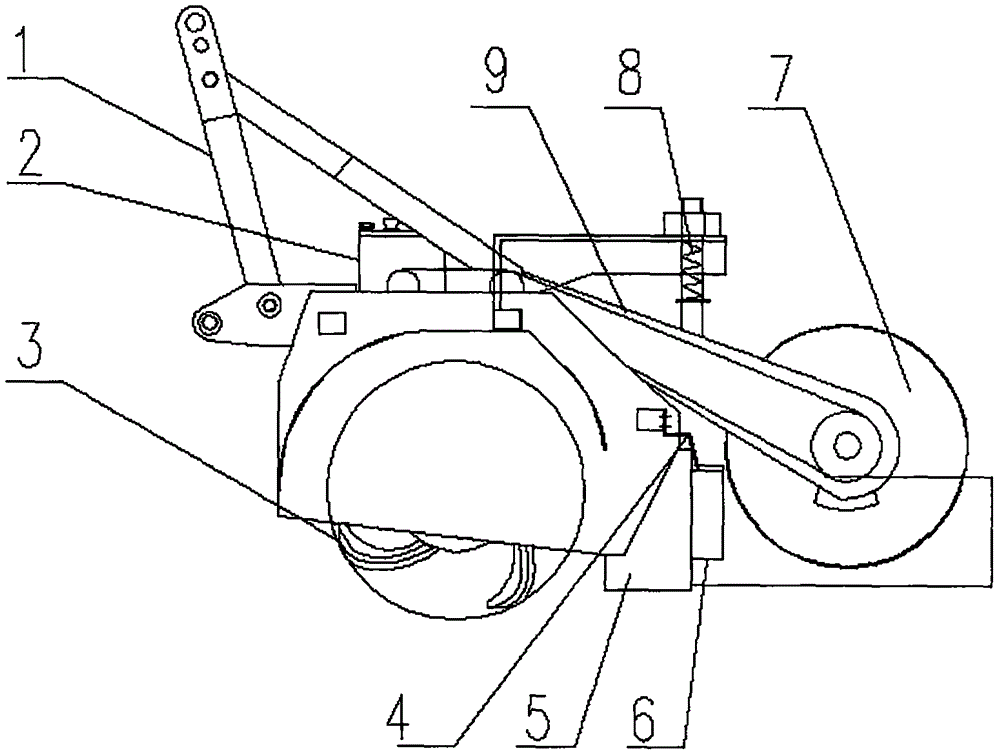

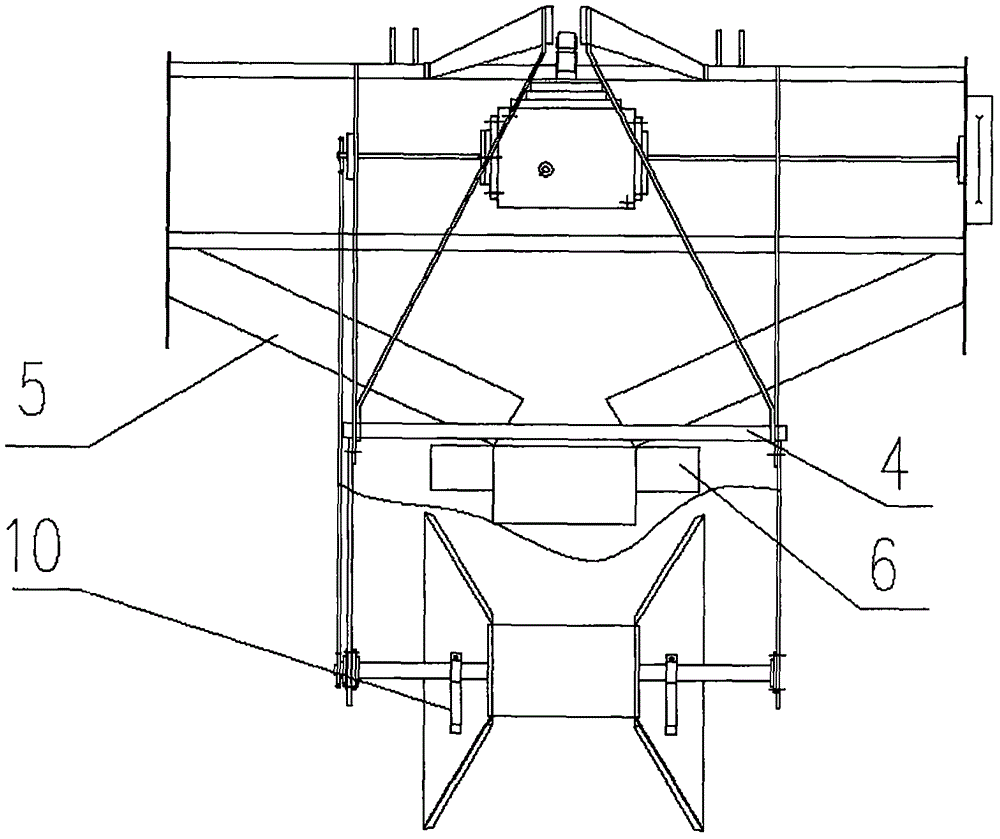

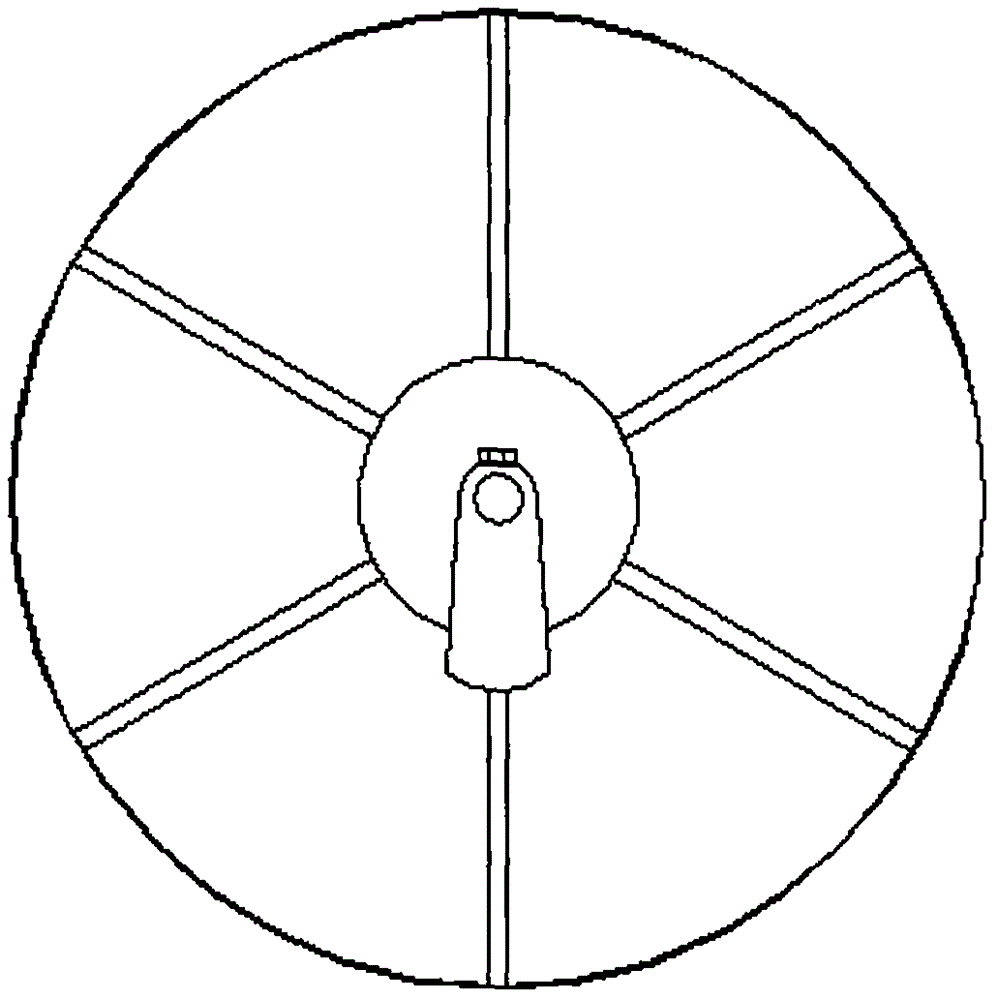

[0011] like figure 1 , figure 2 , image 3 Shown:

[0012] A centrifugal compaction ridge building machine, comprising a suspension frame 1, a frame, a rotary tillage component and a gear box assembly 2, the suspension frame 1 is connected with the frame, the frame is provided with a gear box assembly 2, and the rotary tillage component Including the rotary tiller 3 and the rotary tiller shaft, the rotary tiller is installed on the rotary tiller shaft, the gear box assembly 2 is connected with the rotary tiller shaft through the side chain transmission device, the rotary tiller 3 on the rotary tiller shaft Separate from the middle to form the left and right sides. The left and right rotary tillers are bent to the middle. The left rotary tiller is arranged in a right spiral, and the right rotary tiller is arranged in a left spiral. "Inverted horoscope". The frame is also equipped with a moldboard 5, a top pressure plate 4 and a side forming plate 6, and the moldboard 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com