High durability corn threshing device

A technology for corn threshing and durability, applied in threshing equipment, cutting equipment, cutters, etc., can solve the problems of inability to handle, low threshing efficiency, complex structure, etc., and achieve the effect of improving efficiency, hardness and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

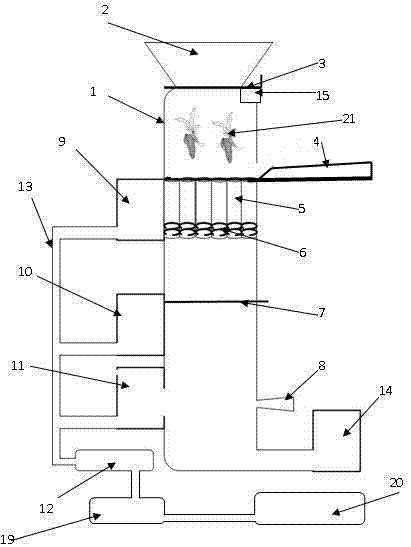

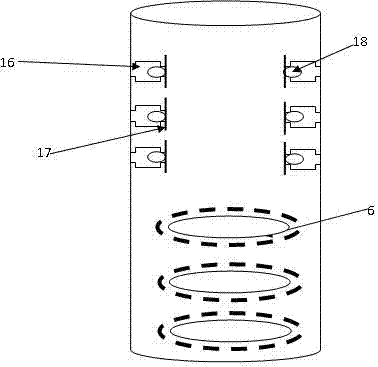

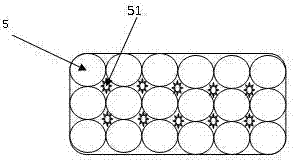

[0029] A high-durability corn threshing device includes a shell, a feeding device, a bract separation device, a corn kernel separation device, a decontamination device, a control device and a by-product recovery device.

[0030] The housing is vertically arranged.

[0031] The feeding device is arranged on the upper part of the shell, and includes a feeding hopper, a feeding control board arranged laterally, and a feeding control board control component.

[0032] The bract separating device includes a bract cutting knife, a bract cutting knife control part, and a bracts collecting and storing box. The bract cutting knife is arranged horizontally, one end of the bract cutting knife is a sharp cutting end, and the other three ends are all A vertical baffle is arranged, a bract collection and storage box is arranged on the side of the cutting end of the bract cutting knife, and a bract cutting knife control part is arranged on the opposite side, and the bract cutting knife control part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com