Friction stir device with adjustable filling pressure and welding method

A technology of filling pressure and friction stir, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as welding defects and missing metal, and achieve the effect of improving performance, metal densification, and reducing the probability of pores and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

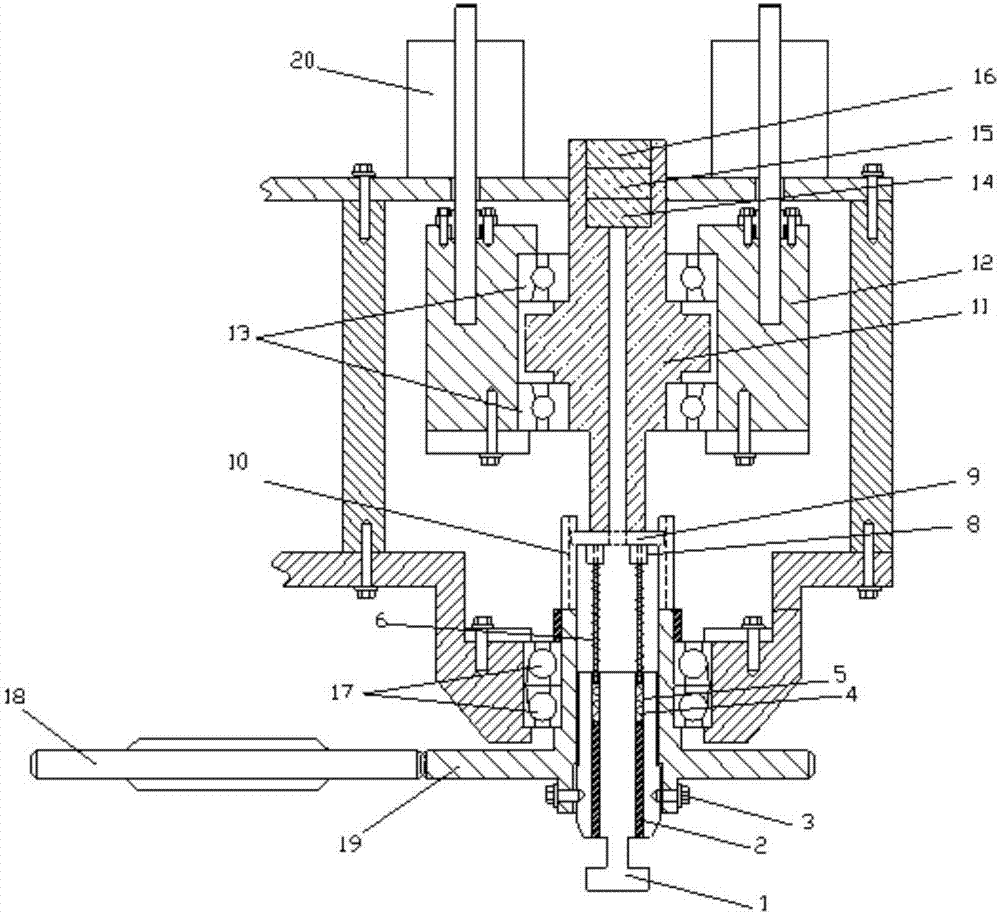

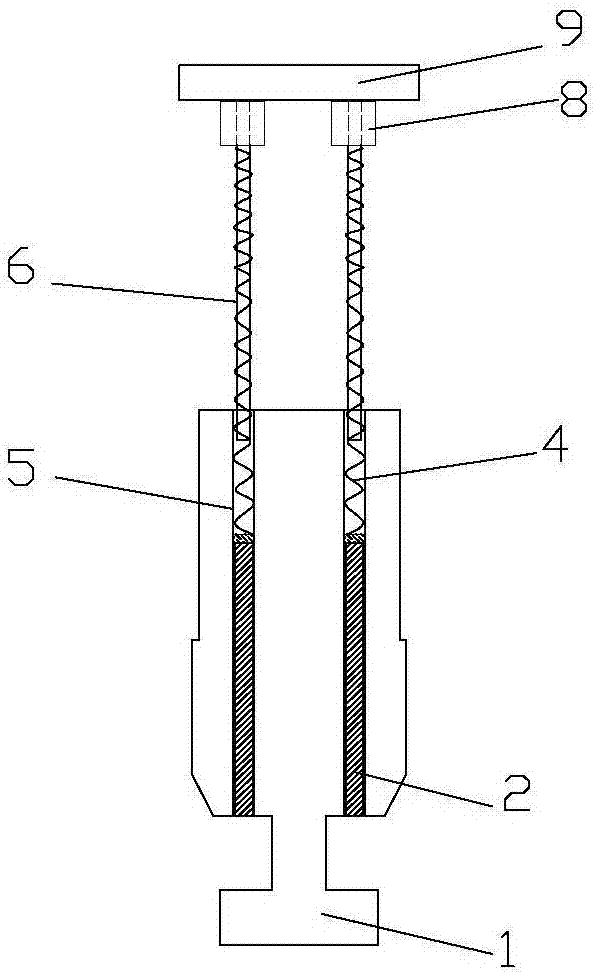

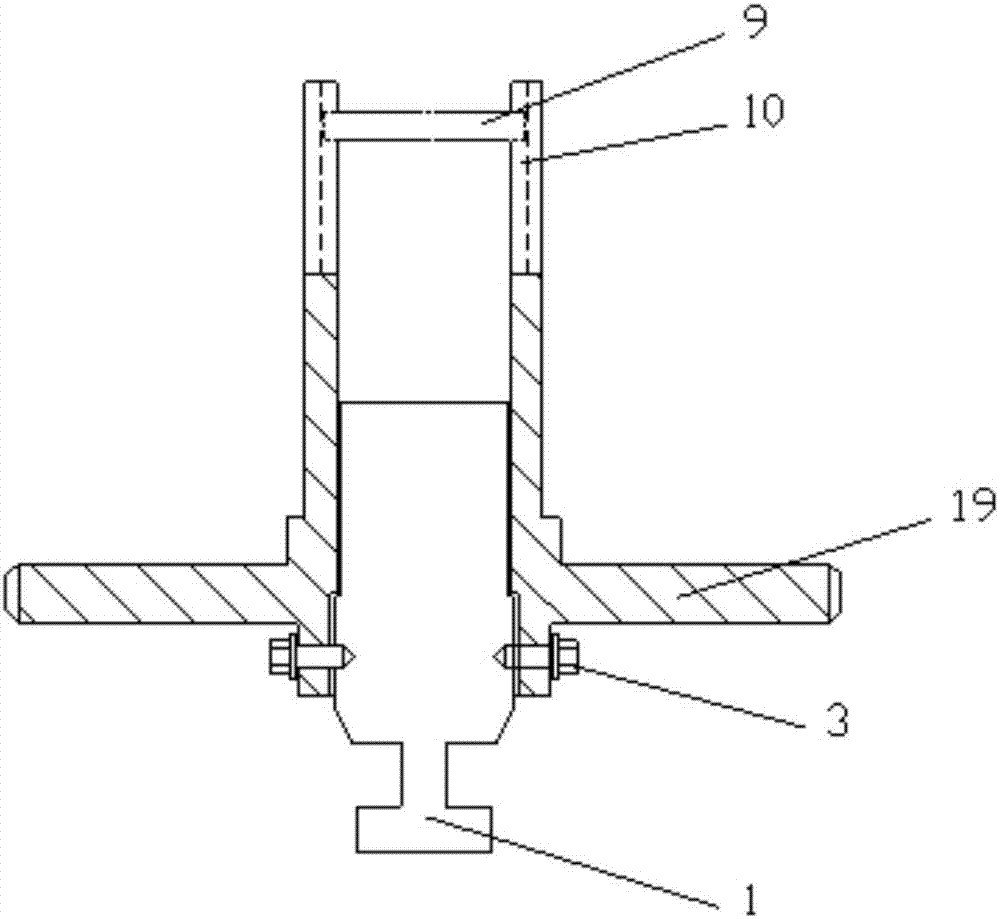

[0026] Such as Figure 1 to Figure 6 As shown, a friction stir device with adjustable filling pressure of the present invention includes a frame on which two linear motors 20 are installed, and each linear motor 20 is connected with a slide block 12 located in the frame, and the slide block 12 There is a cylindrical groove, and a pair of first bearings 13 are installed in the cylindrical groove. The outer ring of the first bearing 13 is clamped by two sliders 12, and the push rod 11 is clamped between the inner rings of the first bearing 13. , the first bearing 13 is sleeved on the push rod 11, the lower end of the push rod 11 is fixedly connected with the support plate 9, and the support plate 9 is fixedly connected with the guide rod 6; Two bearings 17, the second bearing 17 is installed on the rotating device, the second bearing 17 is fixed on the rotating device through a shaft sleeve, the rotating device is fixedly connected with the stirring head body 1, and the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com