Extruding speed-adjustable filling friction stir welding device

A friction stir welding and filling technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of welding defects, metal loss, poor repeatability, etc., and achieve the reduction of porosity and cracks, uniform and moderate force, The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

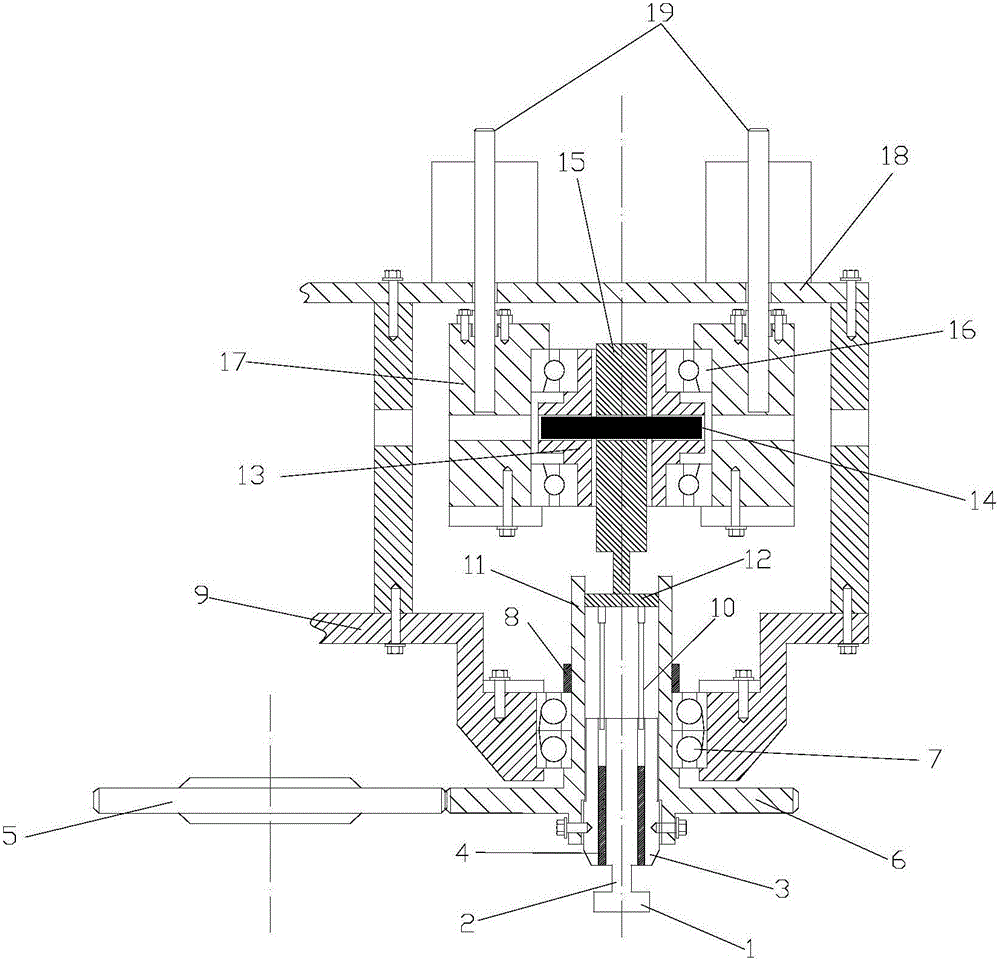

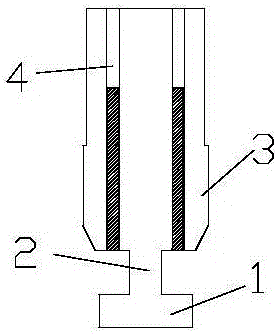

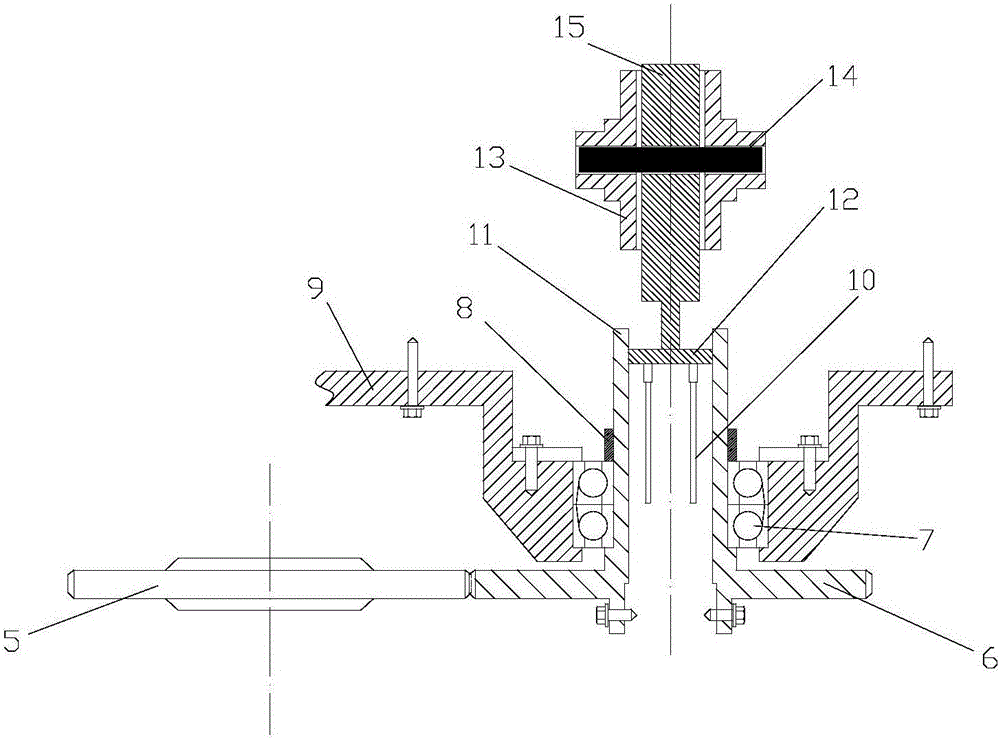

[0026] like Figure 1 to Figure 5 As shown, a filling type friction stir welding device with adjustable extrusion speed of the present invention includes a frame 18 on which several linear motors are installed, and the linear motors are connected to the frame 18 through connecting rods 19. The inner central bushing 17 is connected, and the central bushing 17 is connected with the positioning cylinder 13 through the first bearing 16. There are two first bearings 17, which are respectively located on the two shoulders of the central bushing 17, and the positioning cylinder 13 is set in the center On the shaft 15 and rotate synchronously with the central shaft 15, the central shaft 15 plays the role of transmitting the axial force and resolving the radial force. The central shaft 15 and the positioning cylinder 13 are all provided with through holes, and the positioning key 14 is inserted into the through holes , the central shaft 15 and the positioning cylinder 13 rotate synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com