Cabinet door plate and manufacturing method thereof

A manufacturing method and technology for cabinet door panels, which are applied in the direction of manufacturing tools, wood processing appliances, etc., can solve the problems of inability to fully close or open, insufficient hinge supporting force, poor stability of finger joint boards, etc. Occupational health, the effect of improving the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

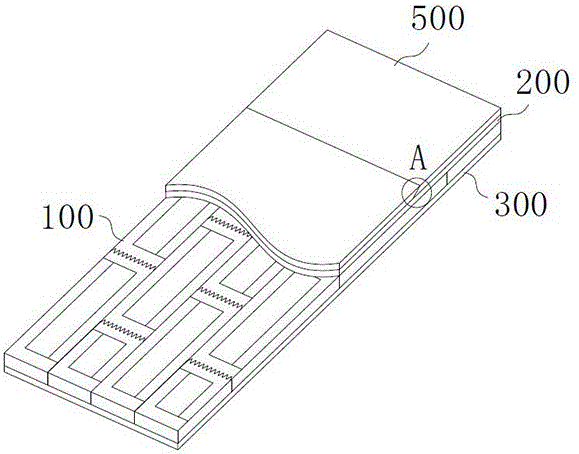

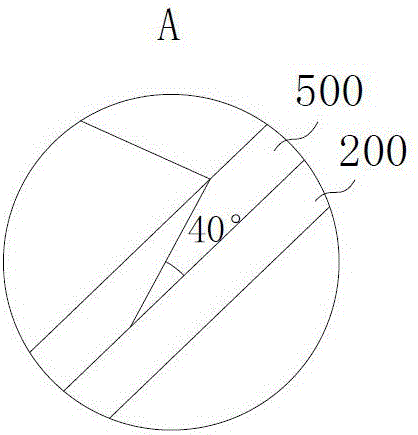

[0037] Embodiment 1: as figure 1 As shown, a cabinet door panel includes a base plate and a liner 200 and a back plate 300 respectively arranged on the front and back sides of the base plate by an adhesive. A leather decoration layer 500 is glued on the top of the liner plate 200. The leather decoration layer 500 includes multiple A decorative single piece, the decorative single piece here is an undyed leather single piece, the width of the decorative single piece is the same as the width of the lining board 200, and the decorative single piece is arranged sequentially along the length direction of the lining board 200, as image 3 As shown, the two sides of the decorative single piece have an angle of 40° with the surface, and two adjacent decorative single pieces are spliced by overlapping the adjacent sides. lap.

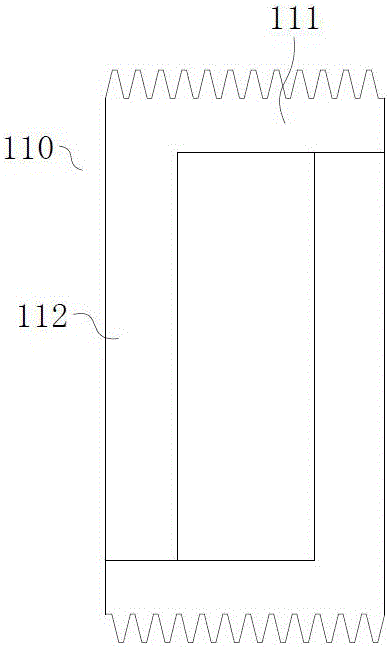

[0038] combine figure 1 and figure 2 As shown, the thickness of the liner 200 is 4 mm, the thickness of the back plate 300 is 6 mm, and the base plate incl...

Embodiment 2

[0047] Embodiment 2: as Figure 4 As shown, a cabinet door panel includes a base plate and a liner 200 and a back plate 300 respectively arranged on the front and back sides of the base plate by an adhesive. A leather decoration layer 500 is glued on the top of the liner plate 200. The leather decoration layer 500 includes multiple A decorative single piece, the decorative single piece here is an undyed leather single piece, the width of the decorative single piece is the same as the width of the liner 200, and the decorative single piece is arranged sequentially along the length direction of the liner 200, the decorative single piece The two sides of the board have an angle of 40° with the surface, and two adjacent decorative single pieces are spliced by overlapping the adjacent sides. The lap joints can be glued or just lapped without glue. The thickness of the liner is 7mm, and the thickness of the backboard is 7mm. The base plate includes a plurality of base plate blocks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com