Blower or induced draft device for pressurization of flammable, explosive and corrosive gases

A corrosive gas, flammable and explosive technology, applied in the direction of elastic fluid rotary piston type/oscillating piston type pump combination, machine/engine, pump, etc., can solve the problem of high cost of magnetic drive, corrosion damage of motor, production promotion Obstacles and other problems, to achieve the effect of simple structure, low cost, and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The first embodiment:

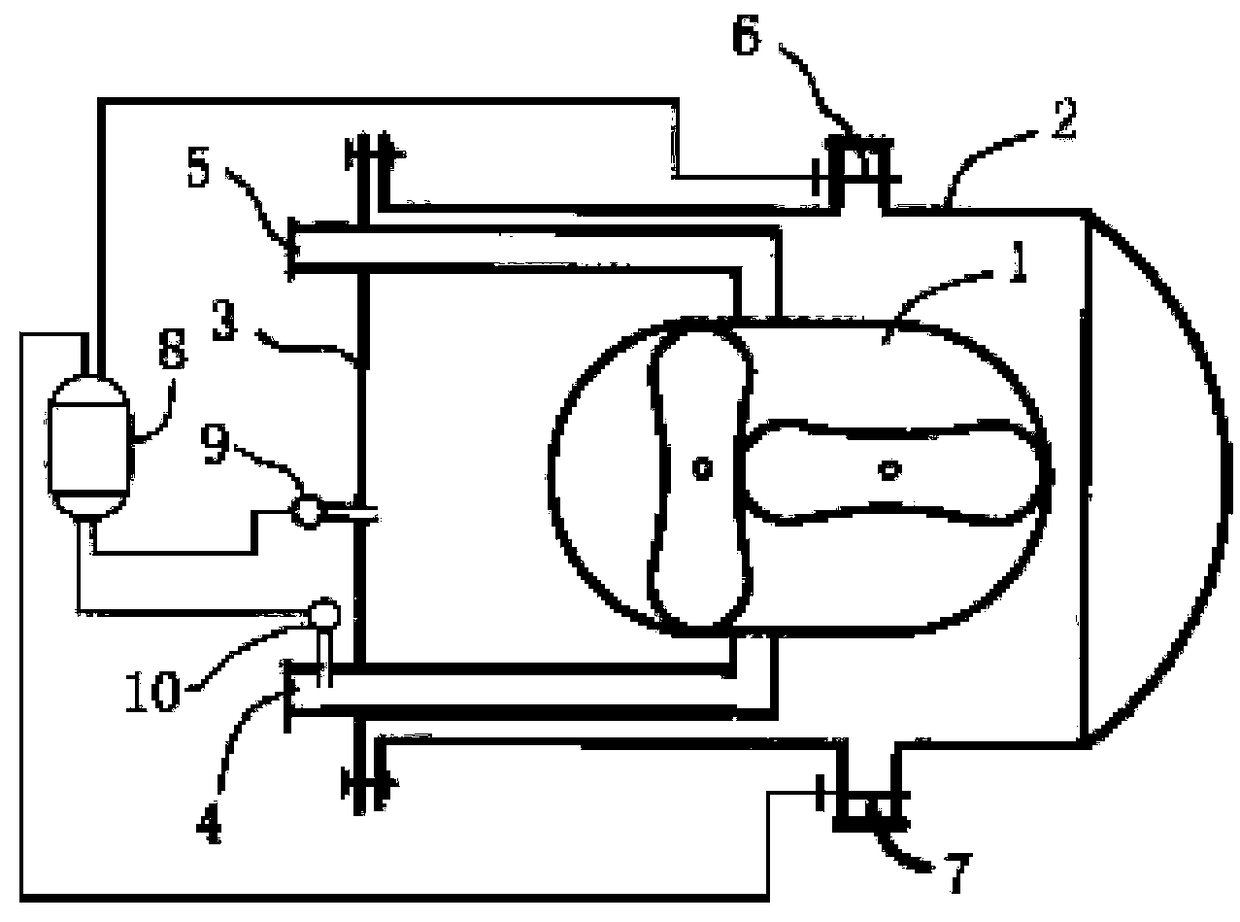

[0023] Such as figure 1 As shown, the blowing or induced draft device for pressurizing flammable, explosive and corrosive gases includes a pressure vessel, a fan 1 and a motor placed in the pressure vessel, and an air inlet 4 and an exhaust port arranged on the pressure vessel 5. The protective gas inlet valve 6 is set on the pressure vessel. The air intake end of the fan is connected to the air inlet, and the air outlet end of the fan is connected to the exhaust port. The pressure vessel is filled with protective gas, and the pressure vessel includes a shell 2 and end cap3.

[0024] The second embodiment:

[0025] Such as figure 1 As shown, the blower or draft device for pressurizing flammable, explosive and corrosive gases includes a pressure vessel and a gas source, a fan 1 and a motor placed in the pressure vessel, an air inlet 4 and an air inlet installed on the pressure vessel. The exhaust port 5, the protective gas inlet valve 6 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com