A maintenance work light

A work light and work technology, which is applied to lighting auxiliary devices, lighting and heating equipment, electric lighting devices with built-in batteries, etc., can solve the problems of difficult maintenance work, troublesome maintenance work, easy loss, etc., and achieve a simple and reliable structure. , The effect of convenient manufacture and loss prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

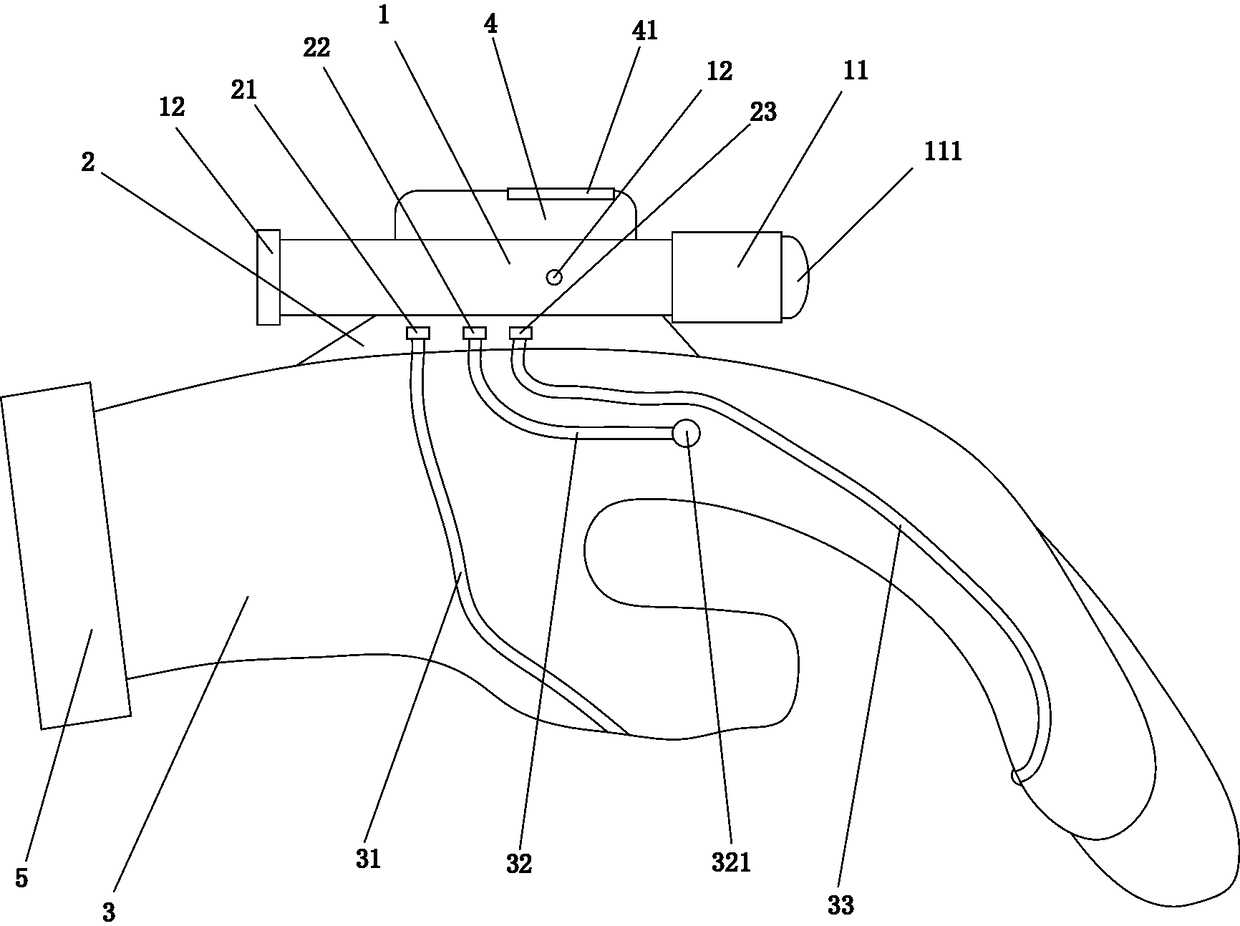

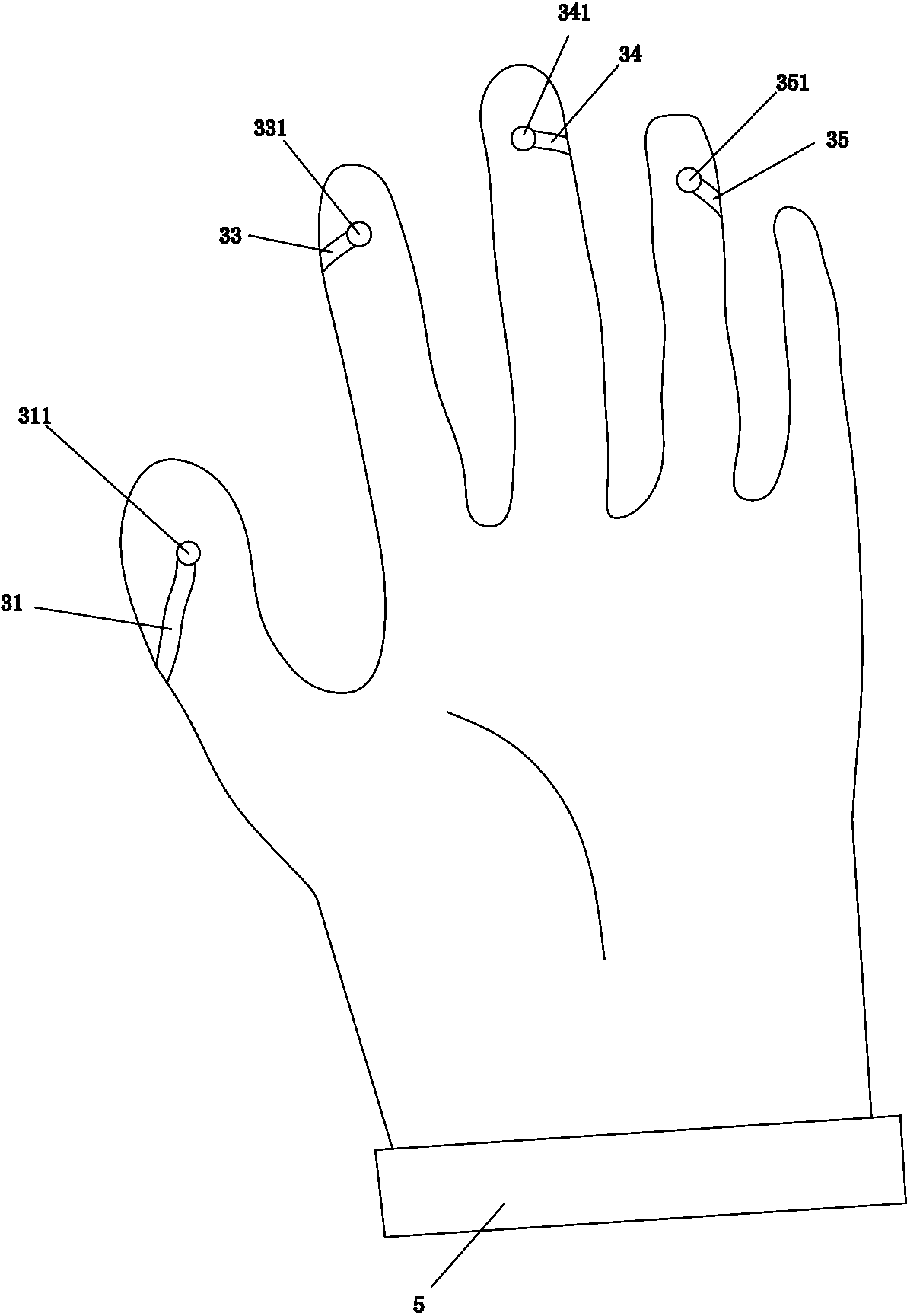

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 2 As shown, a work lamp for inspection and maintenance includes a lamp body 1 and a motor base 2 on which the lamp body 1 is installed. It is connected with the lamp body 1 and can control the rotation of the lamp body 1. The motor base 2 is provided with a first joint 21, a second joint 22 and a third joint 23 on the side of the thumb. A fourth joint and a fifth joint are arranged on the side of the little finger, and the thumb, index finger, middle finger and ring finger of the work glove 3 are respectively provided with a first contact 311, a third contact 331, a fourth Contact 341 and fifth contact 351, the middle part of the side of the index finger of the work glove 3 is provided with a second contact 321, the first contact 311, the second contact 321, the third contact The point 331, the fourth contact 341 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com